SITRANS F flowmeters - ista.com

SITRANS F flowmeters - ista.com

SITRANS F flowmeters - ista.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

■ Overview<br />

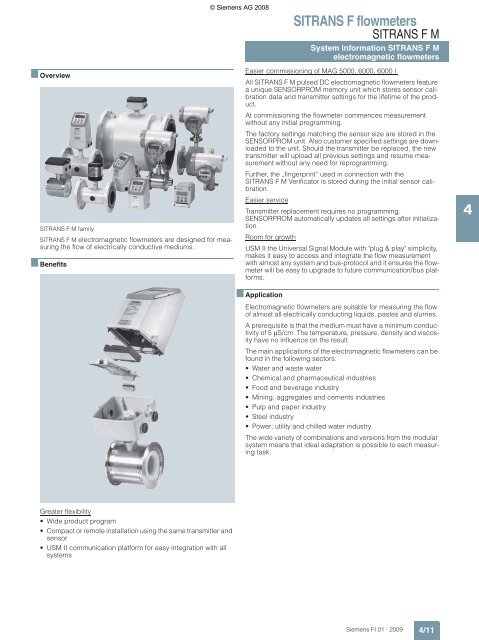

<strong>SITRANS</strong> F M family<br />

<strong>SITRANS</strong> F M electromagnetic <strong>flowmeters</strong> are designed for measuring<br />

the flow of electrically conductive mediums.<br />

■ Benefits<br />

Greater flexibility<br />

• Wide product program<br />

• Compact or remote installation using the same transmitter and<br />

sensor<br />

• USM II <strong>com</strong>munication platform for easy integration with all<br />

systems<br />

©SiemensAG2008<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

System information <strong>SITRANS</strong> F M<br />

electromagnetic <strong>flowmeters</strong><br />

Easier <strong>com</strong>missioning of MAG 5000, 6000, 6000 I<br />

All <strong>SITRANS</strong> F M pulsed DC electromagnetic <strong>flowmeters</strong> feature<br />

a unique SENSORPROM memory unit which stores sensor calibration<br />

data and transmitter settings for the lifetime of the product.<br />

At <strong>com</strong>missioning the flowmeter <strong>com</strong>mences measurement<br />

without any initial programming.<br />

The factory settings matching the sensor size are stored in the<br />

SENSORPROM unit. Also customer specified settings are downloaded<br />

to the unit. Should the transmitter be replaced, the new<br />

transmitter will upload all previous settings and resume measurement<br />

without any need for reprogramming.<br />

Further, the „fingerprint“ used in connection with the<br />

<strong>SITRANS</strong> F M Verificator is stored during the initial sensor calibration.<br />

Easier service<br />

Transmitter replacement requires no programming.<br />

SENSORPROM automatically updates all settings after initialization.<br />

Room for growth<br />

USM II the Universal Signal Module with "plug & play" simplicity,<br />

makes it easy to access and integrate the flow measurement<br />

with almost any system and bus-protocol and it ensures the flowmeter<br />

will be easy to upgrade to future <strong>com</strong>munication/bus platforms.<br />

■ Application<br />

Electromagnetic <strong>flowmeters</strong> are suitable for measuring the flow<br />

of almost all electrically conducting liquids, pastes and slurries.<br />

A prerequisite is that the medium must have a minimum conductivity<br />

of 5 µS/cm. The temperature, pressure, density and viscosity<br />

have no influence on the result.<br />

The main applications of the electromagnetic <strong>flowmeters</strong> can be<br />

found in the following sectors:<br />

• Water and waste water<br />

• Chemical and pharmaceutical industries<br />

• Food and beverage industry<br />

• Mining, aggregates and cements industries<br />

• Pulp and paper industry<br />

• Steel industry<br />

• Power; utility and chilled water industry<br />

The wide variety of <strong>com</strong>binations and versions from the modular<br />

system means that ideal adaptation is possible to each measuring<br />

task.<br />

Siemens FI 01 · 2009<br />

4/11<br />

4

4<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

Transmitter MAG 5000/6000<br />

■ Overview<br />

Transmitter MAG 5000/6000 <strong>com</strong>pact version (left) and 19“ insert version<br />

(right)<br />

The MAG 5000 and 6000 are microprocessor-based transmitters<br />

engineered for high performance, easy installation, <strong>com</strong>missioning<br />

and maintenance. The transmitters evaluate the signals from<br />

the <strong>SITRANS</strong> F M sensors type MAG 1100, MAG 1100 F,<br />

MAG 3100 and MAG 5100 W.<br />

Transmitter types:<br />

• MAG 5000: Max. measuring error 0.5% of rate (incl. sensor)<br />

• MAG 6000: Max. measuring error 0.25% of rate (incl. sensor,<br />

see also sensor specifications) and with additional features<br />

such as: Plug & Play insert bus modules; integrated batch<br />

functions.<br />

■ Benefits<br />

• Superior signal resolution for optimum turn down ratio<br />

• Digital signal processing with many possibilities<br />

• Automatic reading of SENSORPROM data for easy <strong>com</strong>missioning<br />

• User configurable operation menu with password protection.<br />

• 3 lines, 20 characters display in 11 languages.<br />

• Flow rate in various units<br />

• Totalizer for forward, reverse and net flow as well as additional<br />

information available<br />

• Multiple functional outputs for process control, minimum configuration<br />

with analogue, pulse/frequency and relay output<br />

(status, flow direction, limits)<br />

• Comprehensive self-diagnostic for error indication and error<br />

logging (see under <strong>SITRANS</strong> F M diagnostics)<br />

• Batch control<br />

• Custody transfer approval: PTB, OIML R75, R117, OIML R 49<br />

and MI-001,<br />

• MAG 6000 with add-on bus modules for HART, FOUNDATION<br />

Fieldbus H1, DeviceNet, MODBUS RTU/RS485,<br />

PROFIBUS PA and DP<br />

■ Application<br />

The <strong>SITRANS</strong> F M <strong>flowmeters</strong> are suitable for measuring the flow<br />

of almost all electrically conductive liquids, pastes and slurries.<br />

The main applications can be found in:<br />

• Water and waste water<br />

• Chemical and pharmaceutical industries<br />

• Food & beverage industries<br />

• Power generation and utility<br />

4/28<br />

Siemens FI 01 · 2009<br />

©SiemensAG2008<br />

■ Design<br />

The transmitter is designed as either IP67 NEMA 4X enclosure<br />

for <strong>com</strong>pact or wall mounting or 19" version as a 19” insert as a<br />

base to be used in:<br />

• 19" rack systems<br />

• Panel mounting IP65/NEMA 4<br />

• Back of panel mounting IP20/NEMA 2<br />

• Wall mounting IP66/NEMA 4<br />

Several options on 19” versions are available such as:<br />

• Transmitters mounted in safe area for Ex ATEX approved flow<br />

sensors (incl. barriers)<br />

• Transmitters with electrode cleaning unit<br />

■ Function<br />

The MAG 5000/6000 are microprocessor-based transmitters<br />

with a build-in alphanumeric display in several languages. The<br />

transmitters evaluate the signals from the associated electromagnetic<br />

sensors and also fulfil the task of a power supply unit<br />

which provides the magnet coils with a constant current.<br />

Further information on connection, mode of operation and installation<br />

can be found in the data sheets for the sensors.<br />

Displays and controls<br />

Operation of the transmitter can be carried out using:<br />

• Control and display unit<br />

• HART <strong>com</strong>municator<br />

• PC/laptop and SIMATIC PDM software via HART <strong>com</strong>munication<br />

• PC/laptop and SIMATIC PDM software using PROFIBUS or<br />

MODBUS <strong>com</strong>munication<br />

Operating and<br />

display panel<br />

HART <strong>com</strong>munication<br />

Master<br />

Transmitter<br />

HART-<br />

Communicator<br />

PROFIBUS PA <strong>com</strong>munication<br />

+<br />

Coupling<br />

module<br />

PC/<br />

Laptop<br />

RS-232<br />

PROFIBUS DP PROFIBUS PA<br />

Coupler with<br />

power supply<br />

.......<br />

Min. 230W<br />

Transmitter with<br />

PROFIBUS PA interface<br />

T<br />

Bus<br />

terminator

■ Technical specifications<br />

Mode of operation and design<br />

Measuring principle Electromagnetic with pulsed constant<br />

field<br />

Empty pipe Detection of empty pipe (special<br />

cable required in remote mounted<br />

installation)<br />

Excitation frequency Depend on sensor size<br />

Electrode input impedance > 1 x 10 14 Ω<br />

Input<br />

Digital input 11 ... 30 V DC, R i = 4.4 KΩ<br />

• Activation time 50 ms<br />

• Current I DC 11 V = 2.5 mA, I DC 30 V = 7 mA<br />

Output<br />

Current output<br />

• Signal range 0 ... 20 mA or 4 ... 20 mA<br />

• Load < 800 Ω<br />

• Time constant 0.1 … 30 s, adjustable<br />

Digital output<br />

Frequency 0 ... 10 kHz, 50% duty cycle<br />

(uni/bidirectional)<br />

Pulse (active) DC 24 V, 30 mA,<br />

1 KΩ ≤ R i ≤ 10 KΩ, short-circuitprotected<br />

(power supplied from<br />

flowmeter)<br />

Pulse (passive) DC 3 … 30 V, max. 110 mA,<br />

200 Ω ≤ R i ≤ 10 KΩ (powered<br />

from connected equipment)<br />

Time constant 0.1 … 30 s, adjustable<br />

Relay output<br />

Time constant Changeover relay, same as current<br />

output<br />

Load 42 V AC/2 A, 24 V DC/1 A<br />

Low flow cut off 0 ... 9.9% of maximum flow<br />

Galvanic isolation All inputs and outputs are galvanically<br />

isolated<br />

Max. measuring error (incl. sensor<br />

and zero point)<br />

MAG 5000 0.5% of rate<br />

MAG 6000 0.25% of rate<br />

Rated operation conditions<br />

Ambient temperature<br />

• Operation • Display version:<br />

-20 ... +50 °C (-4 ... +122 °F)<br />

• Blind version:<br />

-20 ... +60 °C (-4 ... +140 °F)<br />

• Storage -40 ... +70 °C (-40 ... +158 °F)<br />

Mechanical load<br />

Compact version 18 ... 1000 Hz, 3,17 G rms, sinusoidal<br />

in all directions to<br />

IEC 68-2-36<br />

19“ insert 1 ... 800 Hz, 1 G, sinusoidal in all<br />

directions to IEC 68-2-36<br />

Degree of protection<br />

Compact version IP67/NEMA 4X to IEC 529 and<br />

DIN 40050 (1 mH 2 O 30 min.)<br />

19“ insert IP20/NEMA 2 to IEC 529 and<br />

DIN 40050<br />

©SiemensAG2008<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

Transmitter MAG 5000/6000<br />

EMC performance EN 61326-1 (all environments)<br />

EN 61326-2-5<br />

Display and keypad<br />

Totalizer Two eight-digit counters for forward,<br />

net or reverse flow<br />

Display Background illumination with<br />

alphanumeric text, 3 x 20 characters<br />

to indicate flow rate, totalized<br />

values, settings and faults;<br />

Reverse flow indicated by negative<br />

sign<br />

Time constant Time constant as current output<br />

time constant<br />

Design<br />

Enclosure material<br />

• Compact version Fiber glass reinforced polyamide;<br />

optional (IP67 only):<br />

AISI 316 stainless steel<br />

• 19“-insert Standard 19“ insert of aluminium/steel<br />

(DIN 41494), width:<br />

21 TE, height: 3 HE<br />

• Back of panel IP20/NEMA 2; Aluminium<br />

• Panel mounting IP65/NEMA 4; ABS plastic<br />

• Wall mounting IP66/NEMA 4; ABS plastic<br />

Dimensional drawings<br />

Compact version See dimensional drawings<br />

19“ insert See dimensional drawings<br />

Weight<br />

Compact version 0.75 kg (2 lb)<br />

19“ insert See dimensional drawings<br />

Power supply • 115 ... 230 V AC +10% -15%,<br />

50 ... 60 Hz, 17 VA<br />

• 11 ... 30 V DC or 11 ... 24 V AC<br />

Power consumption • 230 V AC: 17 VA<br />

• 24 V AC : 9 W, I N = 380 mA,<br />

I ST = 8 A (30 ms)<br />

• 12 V DC : 11 W, I N = 920 mA,<br />

I ST = 4 A (250 ms)<br />

Certificates and approvals CE, ULc general purpose, C-tick;<br />

CSA/FM Class 1, div 2<br />

Custody transfer approval<br />

(MAG 5000/6000 CT)<br />

Communication<br />

Standard<br />

• PTB OIML R49 (cold water pattern<br />

approval); MI-001<br />

• PTB and DANAK OIML R75 (hot<br />

water pattern approval)<br />

(MAG 6000 CT)<br />

• PTB and DANAK OIML R117<br />

(cold water/milk, beer etc. pattern<br />

approval) (MAG 6000 CT)<br />

• MAG 5000 Without serial <strong>com</strong>munication or<br />

HART as option<br />

• MAG 6000 Prepared for client mounted addon<br />

modules<br />

Optional (MAG 6000 only) HART, MODBUS RTU/RS485,<br />

FOUNDATION Fieldbus H1,<br />

DeviceNet, PROFIBUS PA,<br />

PROFIBUS DP as add-on modules<br />

• MAG 5000/6000 CT no <strong>com</strong>munication moduls<br />

approved<br />

Siemens FI 01 · 2009<br />

4/29<br />

4

4<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

Transmitter MAG 5000/6000<br />

Safety barrier (e/ia)<br />

Electrode cleaning unit<br />

Cleaning unit<br />

The Siemens cleaning unit can be used with MAG 5000 or 6000<br />

in 19” insert version.<br />

The cleaning unit can be used in applications where the liner<br />

and subsequently the electrodes may be coated with deposits.<br />

If the coating is electrically insulating, the electrode signal will be<br />

reduced. If the coating is electrically inductive, the electrode signal<br />

will be partly short-circuited and in both cases the accuracy<br />

of the meter will decrease (dependent on coating type and thickness).<br />

4/30<br />

Siemens FI 01 · 2009<br />

Application For use with MAG 5000/6000 19” and MAG 1100 Ex ATEX/MAG 3100 Ex ATEX<br />

Ex approval MAG 1100 Ex [EEx e ia] IIB ATEX<br />

Cable parameter<br />

• Electrode<br />

Ambient temperature<br />

MAG 3100 Ex [EEx e ia] IIC ATEX<br />

• During operation -20 ... +50 °C (-4 ... +122 °F)<br />

• During storage -20 ... +70 °C (-4 ... +158 °F)<br />

Enclosure<br />

Group Capacity in µF Inductance in mH<br />

IIC ≤ 4.1 ≤ 80<br />

IIB ≤ 45 ≤ 87<br />

IIA ≤ 45 ≤ 87<br />

• Material Standard 19” insert in aluminium/steel (DIN 41494)<br />

• Width 21 TE (4.75”)<br />

• Height 3 HE (5.25”)<br />

• Rating IP20 / NEMA 2 to EN 60529 and DIN 40050<br />

• Mechanical load 1 g, 1 … 800 Hz sinusoidal in all directions to EN 60068-2-36<br />

EMC performance<br />

• Emission EN 50081-1 (Light industry)<br />

• Immunity EN 50082-2 (Industry)<br />

Application For use with transmitters MAG 5000 and 6000 19” to clean the electrodes on<br />

sensors MAG 1100 or MAG 3100<br />

Cleaning voltage<br />

AC cleaning 60 V AC<br />

DC cleaning 30 V DC<br />

Cleaning period 60 s + 60 s pause period<br />

Relay<br />

• Load 42 V/2 A<br />

NB: Must not be used with intrinsically safe ATEX sensors<br />

NB: Not to be used with sensors with Hastelloy and Tantalum electrodes<br />

Operation Switch relay activated when cleaning is in progress<br />

• Automatic Yes<br />

• Manual No<br />

Indicator lamps LEDs: “ON” and “CLEANING”<br />

Supply voltage and power<br />

consumption<br />

Ambient temperature<br />

• During operation -20 ... +50 °C (-4 ... +122 °F)<br />

• During storage -20 ... +70 °C (-4 ... +158 °F)<br />

Enclosure<br />

115 … 230 V AC, +10% … -15%, 50 … 60 Hz, 7 VA cleaning, 5 VA stand by<br />

11 … 30 V DC / 11 … 24 V AC, 50 … 60 Hz, 7 VA cleaning, 5 VA stand by<br />

• Material Standard 19” insert in aluminium/steel (DIN 41494)<br />

• Width 21 TE (4.75”)<br />

• Height 3 HE (5.25”)<br />

©SiemensAG2008<br />

• Rating IP20 / NEMA 2 to EN 60529 and DIN 40050<br />

• Mechanical load 1 g, 1 … 800 Hz sinusoidal in all directions to EN 60068-2-36<br />

Note:<br />

The cleaning unit cannot be used for inflammable or explosive<br />

media!

Mode of operation<br />

The cleaning unit cleans the electrodes electro-chemically by<br />

applying a voltage to the electrodes for approx. 60 seconds.<br />

While cleaning, the transmitter stores and holds the latest measured<br />

flow reading on the display and also the signal outputs. After<br />

an additional pausing period of 60 seconds the flowmeter resumes<br />

normal measurement and the cleaning is now <strong>com</strong>pleted.<br />

The relay in the transmitter activates the cleaning cycle. In the relay<br />

output menu (under cleaning) the cleaning interval can be<br />

set between 1 hour and 24 hours.<br />

AC cleaning<br />

AC-cleaning is used to remove fatty deposits on the electrodes.<br />

These fatty deposits are seen in waste water applications, in abattoirs<br />

and water applications with oil residuals. During the<br />

cleaning process, the surface of the electrodes get warmer,<br />

which tends to soften grease particles and the gas bubbles generated<br />

mechanically lift deposits away from the surface of the<br />

electrodes.<br />

Note:<br />

Do not use AC-cleaning on sensors with Tantalum or Hastelloy<br />

electrodes.<br />

DC cleaning<br />

DC-cleaning is used to eliminate electrically conductive deposits<br />

in the measuring pipe influencing the measuring accuracy.<br />

Particularly in district heating applications an electrically conductive<br />

deposit (magnetite) may occur and short-circuit the<br />

electrode signal. In this case the accuracy of the meter decreases<br />

and the signal/noise conditions of the meter be<strong>com</strong>e inferior.<br />

The problem only arises if the conductivity of the water is<br />

less than approx. 250 µS/cm.<br />

During DC-cleaning electrolysis takes place where the flow of<br />

electrons removes the particle deposits from the electrode area.<br />

Note:<br />

Do not use DC-cleaning on sensors with Tantalum or Hastelloy<br />

electrodes.<br />

©SiemensAG2008<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

Transmitter MAG 5000/6000<br />

Cleaning should only take place with liquid in the pipe.This can<br />

be detected via the empty pipe function. It is therefore re<strong>com</strong>mended<br />

to select “empty pipe detection” ON when using the<br />

cleaning.<br />

The cleaning sequence can also be controlled manually through<br />

the electrical input of the transmitter. Before this is done, ensure<br />

that the measuring pipe is full.<br />

i £ 20 mA<br />

i £ 80 mA<br />

Siemens FI 01 · 2009<br />

4/31<br />

4

4<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

Transmitter MAG 5000/6000<br />

■ Selection and Ordering Data<br />

Transmitter MAG 5000<br />

Description Order No.<br />

Transmitter MAG 5000 Blind<br />

for <strong>com</strong>pact and wall mounting;<br />

IP67/NEMA 4X, fibreglass<br />

reinforced polyamide<br />

• 11 ... 30 V DC /<br />

11 ... 24 V AC<br />

Transmitter MAG 6000<br />

4/32<br />

Siemens FI 01 · 2009<br />

7ME6910-<br />

1AA30-0AA0<br />

• 115/230 V AC, 50/60 Hz 7ME6910-<br />

1AA10-0AA0<br />

Transmitter MAG 5000 Display<br />

for <strong>com</strong>pact and wall<br />

mounting;<br />

IP67/NEMA 4X, fibre-glass<br />

reinforced polyamide<br />

• 11 ... 30 V DC /<br />

11 ... 24 V AC<br />

} 7ME6910-<br />

1AA30-1AA0<br />

• 115/230 V AC, 50/60 Hz } 7ME6910-<br />

1AA10-1AA0<br />

• 115/230 V AC, 50/60 Hz,<br />

with HART<br />

Transmitter MAG 5000 CT<br />

for <strong>com</strong>pact and wall mounting,<br />

approved for custody<br />

transfer;<br />

IP67/NEMA 4X, fibre-glass<br />

reinforced polyamide<br />

• 11 ... 30 V DC /<br />

11 ... 24 V AC<br />

7ME6910-<br />

1AA10-1BA0<br />

7ME6910-<br />

1AA30-1AB0<br />

• 115/230 V AC, 50/60 Hz 7ME6910-<br />

1AA10-1AB0<br />

Transmitter MAG 5000<br />

for 19” rack and wall mounting<br />

• 11 ... 30 V DC /<br />

11 ... 24 V AC<br />

7ME6910-<br />

2CA30-1AA0<br />

• 115/230 V AC, 50/60 Hz 7ME6910-<br />

2CA10-1AA0<br />

Description Order No.<br />

Transmitter MAG 6000 Blind<br />

for <strong>com</strong>pact and wall mounting;<br />

IP67/NEMA 4X, fibre-glass<br />

reinforced polyamide<br />

• 11 ... 30 V DC /<br />

11 ... 24 V AC<br />

7ME6920-<br />

1AA30-0AA0<br />

• 115/230 V AC, 50/60 Hz 7ME6920-<br />

1AA10-0AA0<br />

Transmitter MAG 6000<br />

for <strong>com</strong>pact and wall mounting;<br />

• 11 ... 30 V DC /<br />

11 ... 24 V AC<br />

7ME6920-<br />

1AA30-1AA0<br />

• 115/230 V AC, 50/60 Hz 7ME6920-<br />

1AA10-1AA0<br />

IP67/NEMA 4X, AISI 316<br />

stainless steel (only for sensor<br />

with SS terminal box )<br />

• 11 ... 30 V DC /<br />

11 ... 24 V AC<br />

7ME6920-<br />

1QA30-1AA0<br />

• 115/230 V AC, 50/60 Hz 7ME6920-<br />

1QA10-1AA0<br />

} Available ex stock<br />

©SiemensAG2008<br />

Description Order No.<br />

Transmitter MAG 6000 CT<br />

for <strong>com</strong>pact and wall mounting,<br />

approved for custody<br />

transfer (no <strong>com</strong>munication<br />

moduls possible);<br />

IP67/NEMA 4X, fibre-glass<br />

reinforced polyamide<br />

• 11 ... 30 V DC /<br />

11 ... 24 V AC<br />

7ME6920-<br />

1AA30-1AB0<br />

• 115/230 V AC, 50/60 Hz 7ME6920-<br />

1AA10-1AB0<br />

Transmitter MAG 6000 SV<br />

for <strong>com</strong>pact and wall mounting;<br />

special excitation 44 Hz<br />

settings for Batch application<br />

DN ≤ 25/1“<br />

IP67/NEMA 4X, fibre-glass<br />

reinforced polyamide<br />

11 ... 30 V DC /<br />

11 ... 24 V AC<br />

7ME6920-<br />

1AB30-1AA0<br />

115/230 V AC, 50/60 Hz 7ME6920-<br />

1AB10-1AA0<br />

Transmitter MAG 6000 for<br />

19“ rack and wall mounting<br />

• 11 ... 30 V DC /<br />

11 ... 24 V AC<br />

7ME6920-<br />

2CA30-1AA0<br />

• 115/230 V AC, 50/60 Hz 7ME6920-<br />

2CA10-1AA0<br />

Transmitter MAG 6000 SV<br />

for 19“ rack and wall mounting;<br />

special excitation 44 Hz<br />

settings for Batch application<br />

DN ≤ 25/1“<br />

• 11 ... 30 V DC /<br />

11 ... 24 V AC<br />

7ME6920-<br />

2CB30-1AA0<br />

• 115/230 V AC, 50/60 Hz 7ME6920-<br />

2CB10-1AA0<br />

MAG 6000 with<br />

IP66/NEMA 4X enclosure;<br />

115/230 V AC, 50/60 Hz<br />

MAG 6000 with electrode<br />

cleaning unit, <strong>com</strong>plete<br />

mounted with<br />

IP66/NEMA 4X mounting<br />

enclosure<br />

• 11 ... 30 V DC /<br />

11 ... 24 V AC<br />

7ME6920-<br />

2EA10-1AA0<br />

7ME6920-<br />

2PA30-1AA0<br />

• 115/230 V AC, 50/60 Hz 7ME6920-<br />

2PA10-1AA0<br />

MAG 6000 with safety barrier<br />

for ATEX 2G D approved<br />

sensors, <strong>com</strong>plete mounted<br />

with IP66/NEMA 4X wall<br />

mounting enclosure, ATEX,<br />

115/230 V AC, 50/60 Hz<br />

• For ATEX 2G D sensors 7ME6920-<br />

2MA11-1AA0<br />

MAG 6000 SV, 19” insert, in<br />

IP66/NEMA 4X , ABS plastic<br />

enclosure, excitation frequency<br />

44 Hz for Batch<br />

application DN ≤ 25/1“,<br />

11 … 30 V DC,<br />

11 … 24 V AC, 50/60 Hz<br />

7ME6920-<br />

2EB30-1AA0

Communication modules for MAG 6000<br />

Description Order No.<br />

HART<br />

(not for MAG 6000 I)<br />

} FDK-085U0226<br />

MODBUS RTU/RS485 } FDK-085U0234<br />

PROFIBUS PA Profile 3 } FDK-085U0236<br />

PROFIBUS DP Profile 3 } FDK-085U0237<br />

DeviceNet } FDK-085U0229<br />

FOUNDATION Fieldbus H1 } A5E02054250<br />

Accessories for MAG 5000 and MAG 6000<br />

Description Order No.<br />

Wall mounting unit for<br />

IP67/NEMA 4X version,<br />

wall bracket, terminal box in<br />

polyamide<br />

• 4 x M20 cable glands } FDK-085U1018<br />

• 4 x ½“ NPT cable glands } FDK-085U1053<br />

Cable for standard electrode<br />

or coil, 3 x 1.5 mm² /<br />

18 gage with shield PVC<br />

• 10 m (33 ft) } FDK-083F0121<br />

• 20 m (65 ft) } FDK-083F0210<br />

• 40 m (130 ft) } FDK-083F0211<br />

• 60 m (200 ft) } FDK-083F0212<br />

• 100 m (330 ft) FDK-083F0213<br />

• 150 m (500 ft) FDK-083F3052<br />

• 200 m (650 ft) FDK-083F3053<br />

• 500 m (1650 ft) FDK-083F3054<br />

Electrode cable for empty<br />

pipe or low conductivity,<br />

double shielded,<br />

3 x 0.25 mm²<br />

• 10 m (33 ft) FDK-083F3020 D)<br />

• 20 m (65 ft) } FDK-083F3095 D)<br />

• 40 m (131 ft) FDK-083F3094 D)<br />

• 60 m (200 ft) FDK-083F3093 D)<br />

• 100 m (330 ft) FDK-083F3092 D)<br />

• 150 m (500 ft) FDK-083F3056 D)<br />

• 200 m (650 ft) FDK-083F3057 D)<br />

• 500 m (1650 ft) FDK-083F3058 D)<br />

Cable kit with standard coil<br />

cable, 3 x 1.5 mm²/18 gage<br />

with shield PVC and electrode<br />

cable double<br />

shielded, 3 x 0.25 mm²<br />

• 10 m (33 ft) A5E01181647 F)<br />

• 20 m (65 ft) A5E01181656 F)<br />

• 40 m (130 ft) A5E01181686 F)<br />

• 60 m (200 ft) A5E01181689 F)<br />

• 100 m (330 ft) A5E01181691 F)<br />

• 150 m (500 ft) A5E01181699 F)<br />

• 200 m (650 ft) A5E01181703 F)<br />

• 500 m (1640 ft) A5E01181705 F)<br />

©SiemensAG2008<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

Description Order No.<br />

Cable glands, for above<br />

cable, 2 pcs.<br />

• M20 A5E00822490<br />

• ½“ NPT A5E00822501<br />

Sealing screws for sensor/<br />

transmitter, 2 pcs<br />

Terminal box, in polyamide,<br />

inclusive lid<br />

Transmitter MAG 5000/6000<br />

FDK-085U0221<br />

• M20 } FDK-085U1050<br />

• ½" NPT FDK-085U1052<br />

Terminal box lid, in polyamid FDK-085U1003<br />

Terminal box for MAG 6000, in<br />

stainless steel, inclusive lid<br />

• M20 A5E00836867<br />

• ½" NPT A5E00836868<br />

Terminal box (3A) for<br />

MAG 1100 Food in polyamide,<br />

inclusive lid<br />

• M20 A5E00822478<br />

• ½" NPT A5E00822479<br />

Potting kit for terminal box of<br />

MAG sensors for<br />

IP68/NEMA 6P (not ATEX)<br />

19“ cleaning unit for electrode<br />

cleaning (21TE) incl.<br />

back plate<br />

• 11 ... 30 V DC /<br />

11 ... 24 V AC<br />

} FDK-085U0220<br />

FDK-083F5039<br />

• 115 ... 230 V AC, 50/60 Hz FDK-083F5036<br />

19“ safety barrier (21 TE)<br />

[EEx e ia] IIC for MAG 1100<br />

ATEX and MAG 3100 ATEX,<br />

incl. back plate<br />

Panel mounting enclosure<br />

for 19“ insert (21 TE);<br />

IP65/NEMA 4 enclosure in<br />

ABS plastic for front panel<br />

mounting<br />

Panel mounting enclosure<br />

for 19“ insert (42 TE);<br />

IP65/NEMA 4 enclosure in<br />

ABS plastic for front panel<br />

mounting<br />

Back of panel mounting<br />

enclosure for 19“ insert<br />

(21 TE); IP20/NEMA 2 enclosure<br />

in aluminium<br />

} Available ex stock<br />

FDK-083F5034<br />

FDK-083F5030<br />

FDK-083F5031<br />

FDK-083F5032<br />

D) Subject to export regulations AL: N, ECCN: EAR99H.<br />

F) Subject to export regulations AL: 9I999, ECCN: N.<br />

½“ NPT<br />

Siemens FI 01 · 2009<br />

M20<br />

4/33<br />

4

4<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

Transmitter MAG 5000/6000<br />

Description Order No.<br />

Back of panel mounting<br />

enclosure for 19“ insert<br />

(42 TE); IP20/NEMA 2 enclosure<br />

in aluminium<br />

IP66/NEMA 4, wall mounting<br />

enclosure for 19“ inserts<br />

(without backplates)<br />

Back plates (if wall enclosure IP66 is used as part)<br />

4/34<br />

Siemens FI 01 · 2009<br />

FDK-083F5033<br />

• 21 TE FDK-083F5037<br />

• 42 TE } FDK-083F5038<br />

Front cover (7TE) FDK-083F4525<br />

} Available ex stock<br />

Description Order No.<br />

Wall unit enclosure IP66,<br />

12 ... 24 V, 115 ... 230 V<br />

• Transmitter FDK-083F4121<br />

• Transmitter ia/e and safety<br />

barrier<br />

• Transmitter ia/ib and safety<br />

barrier (only for sensors<br />

produced before October<br />

2007)<br />

• Transmitter and cleaning<br />

unit<br />

FDK-083F4122<br />

FDK-083F4120<br />

FDK-083F4124<br />

©SiemensAG2008<br />

Spare parts<br />

Description Order No.<br />

Connection plate<br />

• 12 ... 24 V FDK-083F4149<br />

• 115 ... 230 V FDK-083F4148<br />

19“ enclosure, 12 ... 24 V,<br />

115 ... 230 V<br />

• Connection plate for standard<br />

19“ transmitter<br />

• Connection plate for transmitter<br />

ia and safety barrier<br />

• Connection plate for transmitter<br />

ia/ib and safety barrier<br />

(only for sensors<br />

produced before October<br />

2007)<br />

• Connection plate for transmitter<br />

and cleaning unit<br />

SENSORPROM memory unit<br />

(Sensor code and serial<br />

numbers must be specified<br />

on order)<br />

• 2 kB<br />

(for MAG 5000/6000/<br />

MAG 6000 I)<br />

• 250 B<br />

(for MAG 2500/3000)<br />

Display unit<br />

for MAG 5000/6000<br />

FDK-083F4117<br />

FDK-083F4118<br />

FDK-083F4119<br />

FDK-083F4123<br />

FDK-085U1005<br />

FDK-085U1008<br />

• black neutral front FDK-085U1038<br />

• Siemens front FDK-085U1039<br />

Sun Shields for MAG 5000/6000 transmitters<br />

Description Order No.<br />

Sun shield for remote<br />

MAG 5000/6000 transmitters<br />

Sun Shield for <strong>com</strong>pact<br />

MAG 5000/6000 transmitters<br />

on MAG 3100<br />

(DN 15 ... 2000 (½" ... 78") or<br />

MAG 5100<br />

(DN 150 ... 1200 (6" ... 48")<br />

A5E01209496<br />

A5E01209500

■ Dimensional drawings<br />

Transmitter IP67/NEMA 4X <strong>com</strong>pact polyamide<br />

Transmitter <strong>com</strong>pact mounted<br />

Transmitter, 19” IP20/ NEMA 2 standard unit<br />

����������<br />

155 (6.10)<br />

����������<br />

6 (0.24)<br />

����������<br />

���������<br />

131 (5.16)<br />

©SiemensAG2008<br />

178 (7.01)<br />

Transmitter wall mounted<br />

����������<br />

����������<br />

����������<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

���������<br />

����������<br />

��������<br />

Transmitter MAG 5000/6000<br />

���������<br />

���������<br />

���������������������������������������<br />

Siemens FI 01 · 2009<br />

4/35<br />

4

4<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

Transmitter MAG 5000/6000<br />

Transmitter, wall mounting IP66/NEMA 4, 21 TE<br />

13 (0.51)<br />

13(0.51)<br />

Transmitter, wall mounting IP66/NEMA 4, 42 TE<br />

13 (0.51) 90 (3.54) 120 (4.72)<br />

13 (0.51)<br />

4/36<br />

120 (4.72)<br />

90 (3.54)<br />

Siemens FI 01 · 2009<br />

210 (8.27)<br />

192 (7.56)<br />

357 (14.05)<br />

339 (13.35)<br />

Weight excl. transmitter: 2.9 kg (7.0 lbs)<br />

©SiemensAG2008<br />

22 (0.86)<br />

146 (5.75)<br />

90 (3.54)<br />

22 (0.87)<br />

90 (3.54) 146 (5.75)<br />

235 (9.25)<br />

Weight excl. transmitter: 2.3 kg (5.0 lbs)<br />

235 (9.25)

Transmitter, panel front IP65/NEMA 4, 21 TE<br />

144 (5.67)<br />

197 (7.75)<br />

Weight excl. transmitter: 1.2 kg (2.7 lbs)<br />

Transmitter, panel front IP65/NEMA 4, 42 TE<br />

144 (5.67)<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

184 (7.24) 198 (7.80) 50 (1.97)<br />

294 (1.57)<br />

281 (1.06)<br />

Weight excl. transmitter: 1.6 kg (3.5 lbs)<br />

©SiemensAG2008<br />

140 (5.51)<br />

140 (5.51)<br />

185 (7.28)<br />

Transmitter MAG 5000/6000<br />

198 (7.80) 50 (1.97)<br />

282 (1.10)<br />

Siemens FI 01 · 2009<br />

4/37<br />

4

4<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

Transmitter MAG 5000/6000<br />

Transmitter, back of panel IP20/NEMA 2, 21 TE<br />

4/38<br />

132 (5.20)<br />

57 (2.24)<br />

Weight: 0.7 kg (1.6 lbs)<br />

Transmitter, back of panel IP20/NEMA 2, 42 TE<br />

132 (5.20)<br />

57 (2.24)<br />

Weight: 0.9 kg (2.0 lbs)<br />

Siemens FI 01 · 2009<br />

163 (6.42)<br />

144 (5.67)<br />

269 (10.59)<br />

253 (9.96)<br />

©SiemensAG2008<br />

218 (8.58)<br />

218 (8.58)

■ Schematics<br />

Electrical connection<br />

Grounding<br />

PE must be connected due to safety class 1 power supply.<br />

Mechanical counters<br />

When mounting a mechanical counter to terminals 57 and 58<br />

(active output), a 1000 µF capacitor must be connected to the<br />

terminals 56 and 58. Capacitor + is connected to terminal 56<br />

and capacitor - to terminal 58.<br />

Output cables<br />

If the output cable length is long in noisy environment, we<br />

re<strong>com</strong>mend to use screened cable.<br />

1)<br />

������������<br />

� �<br />

�<br />

Shield<br />

1) Note<br />

Special cable with individual wire shields (shown as dotted lines)<br />

are only required when using empty pipe function or long cables<br />

�<br />

�<br />

©SiemensAG2008<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

Transmitter MAG 5000/6000<br />

Siemens FI 01 · 2009<br />

4/39<br />

4

4<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

MAG 5100 W<br />

■ Overview<br />

The <strong>SITRANS</strong> F M MAG 5100 W is an electromagnetic flow sensor<br />

designed to meet ground water, drinking water, waste water,<br />

sewage or sludge applications.<br />

■ Benefits<br />

• DN 25 to DN 1200 (1” to 48”)<br />

• Connection flanges EN 1092-1 (DIN 2501), ANSI, AWWA and<br />

AS.<br />

• NBR Hard Rubber liner for all water applications<br />

• Drinking water EPDM liner with approvals<br />

• Hastelloy integrated grounding and measuring electrodes<br />

• Increased low flow accuracy for water leak detection, due to<br />

coned liner design.<br />

• Drinking water approvals<br />

• Suitable for direct burial and constant flooding<br />

• Build-in length according to ISO 13359<br />

• Easy <strong>com</strong>missioning, SENSORPROM unit automatically uploads<br />

calibration values and settings.<br />

• Designed that patented in-situ verification can be conducted.<br />

Using SENSORPROM fingerprint.<br />

4/58<br />

Siemens FI 01 · 2009<br />

©SiemensAG2008<br />

■ Application<br />

The main applications of the <strong>SITRANS</strong> F M electromagnetic flow<br />

sensors can be found in the following fields:<br />

• Water abstraction<br />

• Water treatment<br />

• Water distribution network (leak detection management)<br />

• Custody transfer water meters<br />

• Irrigation<br />

• Waste water treatment<br />

• Filtration plant (e.g. reverse osmosis and ultra filtration)<br />

• Industrial water applications<br />

■ Mode of operation<br />

The flow measuring principle is based on Faradays law of electromagnetic<br />

induction were the sensor converts the flow into an<br />

electrical voltage proportional to the velocity of the flow.<br />

■ Function<br />

• Highly res<strong>ista</strong>nt to a wide range of chemicals<br />

- Pattern approval OIML R49 (Denmark, Germany)<br />

- conforms to ISO 4064 and EN 14154<br />

- MI-001 Custody Transfer approval for billing (EU)<br />

• Meets EEC directives: PED, 97/23/EC pressure directive for<br />

EN1092-1 flanges<br />

• Simple onsite or factory upgrade to IP68/NEMA 6P of a standard<br />

sensor.<br />

■ Integration<br />

The <strong>com</strong>plete flowmeter consists of a flow sensor and an associated<br />

transmitter <strong>SITRANS</strong> F M MAG 5000, MAG 6000 or<br />

MAG 6000 I.<br />

The flexible <strong>com</strong>munication concept USM II simplifies integration<br />

and update to a variety of fieldbus systems, e.g. HART,<br />

FOUNDATION Fieldbus H1, DeviceNet, PROFIBUS DP and PA,<br />

MODBUS RTU/RS485.

■ Technical specifications<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

Design Full bore sensor Coned bore sensor Full bore sensor<br />

Siemens FI 01 · 2009<br />

MAG 5100 W<br />

Nominal size DN 25 ... 40 (1” ... 1½”) DN 50 ... 300 (2” ... 12”) DN 350 ... 1200 (14” ... 48”)<br />

Measuring principle Electromagnetic induction<br />

Excitation frequency 12.5 Hz • DN 50 ... 65 (2” ... 2½“): 12.5 Hz<br />

• DN 80 ... 150 (3” ... 6“): 6.25 Hz<br />

Process connection<br />

• DN 200 ... 300 (8” ... 12“):<br />

3.125 Hz<br />

Flanges Flat face flanges<br />

• EN 1092-1 PN 40 (580 psi) • DN 50 ... 300: PN 16<br />

(2“ ... 12“: 230 psi)<br />

• DN 200 ... 300: PN 10<br />

(8“ ... 12“: 145 psi)<br />

• ANSI B16.5 Class 150 lb Class 150 lb ~20 bar (290 psi) --<br />

1.56 Hz<br />

• PN 10 (145 psi)<br />

• PN 16 (230 psi)<br />

• AWWA C-207 -- -- 28” ... 48”: Class D<br />

• AS4087 PN 16 (230 psi) DN 50 ... 1200 (2" ... 48"), 14 bar (232 psi)<br />

Rated Operation conditions<br />

Ambient temperature<br />

• Sensor -40 ... +70 °C (-40 ... +158 °F)<br />

• With <strong>com</strong>pact transmitter<br />

MAG 5000/6000<br />

• With <strong>com</strong>pact transmitter<br />

MAG 6000 I<br />

-20 ... +50 °C (-4 ... +122 °F)<br />

-20 ... +60 °C (-4 ... +140 °F)<br />

Operating pressure (Abs) 0.01 ... 40 bar (0.15 ... 580 psi) 0.03 ... 20 bar (0.44 ... 290 psi) 0.01 ... 16 bar (0.15 ... 232 psi)<br />

Enclosure rating<br />

• Standard IP67 to EN 60529 / NEMA 4X/6 (1 mH 2O for 30 minutes)<br />

• Option IP68 to EN 60529 / NEMA 6P (10 mH 2 O continuously)<br />

Pressure drop at 3 m/s (10 ft/s) As straight pipe Max. 25 mbar (0.36 psi) As straight pipe<br />

Medium conditions<br />

Temperature of medium<br />

• NBR -10 ... +70 °C (14 ... +158 °F)<br />

• EPDM -10 ... +70 °C (14 ... +158 °F)<br />

EMC 89/336 EEC<br />

Design<br />

Weight See dimensional drawings<br />

Material<br />

• Housing and flanges Carbon steel, St 37.2<br />

• Terminal box Standard Fibre glass reinforced polyamide<br />

• Measuring pipe AISI 304 (1.4301)<br />

• Liner NBR Hard Rubber (hydro carbon resistent)<br />

EPDM<br />

• Electrodes Hastelloy C276<br />

• Grounding electrodes standard Hastelloy C276<br />

Certificates and approvals<br />

Custody Transfer (only together with<br />

MAG 5000/6000 CT), order as special<br />

Approvals CSA/FM Class 1, Div 2<br />

Drinking water approvals<br />

OIML R 49 pattern approval cold water (Denmark and Germany): DN 50 ... 300 (2“ ... 12")<br />

MI 001 cold water (EU): DN 50 ... 300 (2“ ... 12")<br />

• EPDM NSF61 (Cold water, US)<br />

WRAS (WRc, BS6920 cold water, GB)<br />

ACS listed (F),<br />

DVGW W270 (D)<br />

Belaqua (B)<br />

• NBR NSF61 (Cold water, US)<br />

Approvals PED – 97/23 EC 1) , CRN<br />

©SiemensAG2008<br />

1) For sizes larger than 600 mm (24”) in PN 16 PED conformity is available as a cost added option. The basic unit will carry the LVD (Low Voltage Directive) and<br />

EMC approval.<br />

4/59<br />

4

4<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

MAG 5100 W<br />

Selection and Ordering data Order No.<br />

<strong>SITRANS</strong> F M Flowsensor MAG 5100 W<br />

Hastelloy electrodes, carbon steel flanges<br />

Diameter<br />

DN 25 (1“) } 2 D<br />

DN 40 (1½“) } 2 R<br />

DN 50 (2“) } 2 Y<br />

DN 65 (2½“) } 3 F<br />

DN 80 (3“) } 3 M<br />

DN 100 (4“) } 3 T<br />

DN 125 (5“) } 4 B<br />

DN 150 (6“) } 4 H<br />

DN 200 (8“) } 4 P<br />

DN 250 (10“) } 4 V<br />

DN 300 (12“) } 5 D<br />

DN 350 (14“) } 5 K<br />

DN 400 (16“) } 5 R<br />

DN 450 (18“) } 5 Y<br />

DN 500 (20“) } 6 F<br />

DN 600 (24“) } 6 P<br />

DN 700 (28“) } 6 Y<br />

DN 750 (30“) } 7 D<br />

DN 800 (32“) } 7 H<br />

DN 900 (36“) } 7 M<br />

DN 1000 (40“) } 7 R<br />

42“ } 7 U<br />

44“ } 7 V<br />

DN 1200 (48“) } 8 B<br />

Flange norm and pressure rating<br />

to EN 1092-1<br />

PN 10 (DN 200 ... 1200/8“ ... 48“) } B<br />

PN 16 (DN 50 ... 1200/2“ ... 48“) } C<br />

PN 16, non PED (DN 700 ... 1200/28“ ... 48“) D<br />

PN 40 (DN 25 ... 40/1“ ... 1½“) } F<br />

to ANSI B16.5<br />

class 150 (1“ ... 24“) } J<br />

to AWWA C-207<br />

Class D (28“ ... 48“) L<br />

to AS 4087<br />

PN 16 N<br />

Liner material<br />

4/60<br />

Siemens FI 01 · 2009<br />

7 M E 6 5 2 0 -<br />

777 17 - 2777<br />

EPDM 2<br />

NBR Hard Rubber 3<br />

Transmitter<br />

Sensor for remote transmitter (Order transmitter<br />

separately)<br />

MAG 6000 I, Aluminum, 18 ... 90 V DC,<br />

115 ... 230 V AC<br />

MAG 6000, Polyamid, 11 ... 30 V DC/11 ... 24V AC H<br />

MAG 6000, Polyamid, 115/230 V AC J<br />

MAG 5000, Polyamid, 11 ... 30 V DC/11 ... 24V AC K<br />

MAG 5000, Polyamid, 115/230 V AC L<br />

©SiemensAG2008<br />

A<br />

C<br />

Selection and Ordering data Order No.<br />

<strong>SITRANS</strong> F M Flowsensor MAG 5100 W<br />

Hastelloy electrodes, carbon steel flanges<br />

Communication<br />

None } A<br />

HART B<br />

PROFIBUS PA Profile 3<br />

(only MAG 6000/MAG 6000 I)<br />

F<br />

PROFIBUS DP Profile 3<br />

(only MAG 6000/MAG 6000 I)<br />

G<br />

MODBUS RTU/RS 485<br />

(only MAG 6000/MAG 6000 I)<br />

E<br />

FOUNDATION Fieldbus H1<br />

(only MAG 6000/MAG 6000 I)<br />

J<br />

Cable glands/terminal box<br />

Metric 1<br />

½" NPT 2<br />

} Available ex stock<br />

Selection and Ordering data Order code<br />

Additional information<br />

Please add “-Z“ to Order No. and specify Order<br />

code(s) and plain text.<br />

Customer specific converter setup Y20<br />

Tag name plate, stainless steel fixed with SS wire<br />

(add plain text)<br />

,<br />

MAG 5000/6000 transmitters and sensors are packed in separate<br />

boxes, the final assembly takes place during installation at<br />

the customer's place. MAG 6000 I transmitters and sensors are<br />

delivered <strong>com</strong>pact mounted from factory.<br />

Communication module will be pre-mounted in the transmitter.<br />

Please use online Product selector to get latest updates.<br />

Product selector link:<br />

www.pia-selector.automation.siemens.<strong>com</strong><br />

Y17<br />

Tag name plate, plastic (self adhesive) Y18<br />

Factory certificate according to EN 10204-2.1 C15<br />

Factory certificate according to EN 10204-2.2 C14<br />

Sensor cables wired (specify cable order no.) Y40<br />

Sensor for remote transmitter's junction box potted to<br />

IP68 with wired cable (specify cable order no.)<br />

Y41<br />

Other postproduction requirements (add desired text) Y99<br />

Description Order No.<br />

Potting kit for terminal box<br />

of <strong>SITRANS</strong> F M sensors for<br />

IP68/NEMA 6P (Not ATEX)<br />

FDK-085U0220<br />

7 M E 6 5 2 0 -<br />

Please also see www.siemens.<strong>com</strong>/<strong>SITRANS</strong>Fordering<br />

for practical examples of ordering<br />

777 17 - 2777

■ Dimensional drawings<br />

- not available<br />

DN 25...40<br />

DN 350...1200<br />

A 153 (6.0)<br />

Nominal size A L<br />

L<br />

©SiemensAG2008<br />

M20 (½" NPT)<br />

153 (6.0)<br />

A<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

L<br />

M20 (½" NPT)<br />

PN 10 PN 16 PN 40 Class 150 / AWWA AS<br />

Siemens FI 01 · 2009<br />

MAG 5100 W<br />

DN 50...300<br />

[mm] [inch] [mm] [inch] [mm] [inch] [mm] [inch] [mm] [inch] [mm] [inch] [mm] [inch]<br />

25 1 187 7.4 - - - - 200 7.9 200 7.9 200 7.87<br />

40 1½ 197 7.8 - - - - 200 7.9 200 7.9 200 7.87<br />

50 2 188 7.4 - - 200 7.9 - - 200 7.9 200 7.87<br />

65 2½ 194 7.6 - - 200 7.9 - - 200 7.9 200 7.87<br />

80 3 200 7.9 - - 200 7.9 - - 200 7.9 200 7.87<br />

100 4 207 8.1 - - 250 9.8 - - 250 9.8 250 9.84<br />

125 5 217 8.5 - - 250 9.8 - - 250 9.8 250 9.84<br />

150 6 232 9.1 - - 300 11.8 - - 300 11.8 300 11.81<br />

200 8 257 10.1 350 13.8 350 13.8 - - 350 13.8 350 13.78<br />

250 10 284 11.2 450 17.7 450 17.7 - - 450 17.7 450 17.72<br />

300 12 310 12.2 500 19.7 500 19.7 - - 500 19.7 500 19.69<br />

350 14 382 15.0 550 21.7 550 21.7 - - 550 21.7 550 21.65<br />

400 16 407 16.0 600 23.6 600 23.6 - - 600 23.6 600 23.62<br />

450 18 438 17.2 600 23.6 600 23.6 - - 600 23.6 600 23.62<br />

500 20 463 18.2 600 23.6 600 23.6 - - 600 23.6 600 23.6<br />

600 24 514 20.2 600 23.6 600 23.6 - - 600 23.6 600 23.6<br />

700 28 564 22.2 700 27.6 700 27.6 - - 700 27.6 700 27.6<br />

750 30 591 23.3 - - - - - - 750 29.5 750 -<br />

800 32 616 24.3 800 31.5 800 31.5 - - 800 31.5 800 31.5<br />

900 36 663 26.1 900 35.4 900 35.4 - - 900 35.4 900 35.4<br />

1000 40 714 28.1 1000 39.4 1000 39.4 - - 1000 39.4 1000 39.4<br />

42 714 28.1 - - - - - - 1000 39.4 - -<br />

44 765 30.1 - - - - - - 1100 43.3 - -<br />

1200 48 820 32.3 1200 47.2 1200 47.2 - - 1200 47.2 1200 47.2<br />

4/61<br />

4

4<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

MAG 5100 W<br />

MAG 5100 W / 6000 I Compact<br />

- not available<br />

4/62<br />

218 (8.58)<br />

131 (5.16) 155 (6.10)<br />

Siemens FI 01 · 2009<br />

1<br />

A<br />

Nominal size A A 1 L<br />

©SiemensAG2008<br />

208 (8.19)<br />

L<br />

2 x M25<br />

M20 (½“ NPT)<br />

A<br />

1<br />

A<br />

208 (8.19)<br />

155 (6.10)<br />

PN 10 PN 16 PN 40 Class 150/AWWA AS<br />

L<br />

2 x M25<br />

M20 (½“ NPT)<br />

[mm] [inch] [mm] [inch] [mm] [inch] [mm] [inch] [mm] [inch] [mm] [inch] [mm] [inch] [mm] [inch]<br />

25 1 187 7.4 340 13.4 - - - - 200 7.9 200 7.9 200 7.87<br />

40 1½ 197 7.8 350 13.8 - - - - 200 7.9 200 7.9 200 7.87<br />

50 2 188 7.4 341 13.4 - - 200 7.9 - - 200 7.9 200 7.87<br />

65 2½ 194 7.6 347 13.7 - - 200 7.9 - - 200 7.9 200 7.87<br />

80 3 200 7.9 353 13.9 - - 200 7.9 - - 200 7.9 200 7.87<br />

100 4 207 8.1 360 14.2 - - 250 9.8 - - 250 9.8 250 9.84<br />

125 5 217 8.5 370 14.6 - - 250 9.8 - - 250 9.8 250 9.84<br />

150 6 232 9.1 385 15.2 - - 300 11.8 - - 300 11.8 300 11.81<br />

200 8 257 10.1 410 16.1 350 13.8 350 13.8 - - 350 13.8 350 13.78<br />

250 10 284 11.2 437 17.2 450 17.7 450 17.7 - - 450 17.7 450 17.72<br />

300 12 310 12.2 463 18.2 500 19.7 500 19.7 - - 500 19.7 500 19.69<br />

350 14 382 15.0 535 21.1 550 21.7 550 21.7 - - 550 21.7 550 21.65<br />

400 16 407 16.0 560 22.1 600 23.6 600 23.6 - - 600 23.6 600 23.62<br />

450 18 438 17.2 591 23.3 600 23.6 600 23.6 - - 600 23.6 600 23.62<br />

500 20 463 18.2 616 24.3 600 23.6 600 23.6 - - 600 23.6 600 23.6<br />

600 24 514 20.2 667 26.3 600 23.6 600 23.6 - - 600 23.6 600 23.6<br />

700 28 564 22.2 717 28.2 700 27.6 700 27.6 - - 700 27.6 700 27.6<br />

750 30 591 23.3 744 29.3 - - - - - - 750 29.5 750 -<br />

800 32 616 24.3 779 30.7 800 31.5 800 31.5 - - 800 31.5 800 31.5<br />

900 36 663 26.1 826 32.5 900 35.4 900 35.4 - - 900 35.4 900 35.4<br />

1000 40 714 28.1 877 34.5 1000 39.4 1000 39.4 - - 1000 39.4 1000 39.4<br />

42 714 28.1 877 34.5 - - - - - - 1000 39.4 - -<br />

44 765 30.1 928 36.5 - - - - - - 1100 43.3 - -<br />

1200 48 820 32.3 983 38.7 1200 47.2 1200 47.2 - - 1200 47.2 1200 47.2<br />

A

Weight<br />

©SiemensAG2008<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

Nominal size PN 10 PN 16 PN 40 Class 150/AWWA AS<br />

Siemens FI 01 · 2009<br />

MAG 5100 W<br />

[mm] [inch] [kg] [lbs] [kg] [lbs] [kg] [lbs] [kg] [lbs] [kg] [lbs]<br />

25 1 - - - - 4 9 4 9 4 9<br />

40 1½ - - - - 7 15 6 13 7 15<br />

50 2 - - 9 20 - - 8 20 9 20<br />

65 2½ - - 10.7 24 - - 11 24 10.7 24<br />

80 3 - - 11.6 26 - - 13 28 11.6 26<br />

100 4 - - 15.2 33 - - 19 41 15.2 33<br />

125 5 - - 20.4 45 - - 24 52 20.4 45<br />

150 6 - - 26 57 - - 29 64 26 57<br />

200 8 48 106 48 106 - - 56 124 48 106<br />

250 10 64 141 69 152 - - 79 174 69 152<br />

300 12 76 167 86 189 - - 110 243 86 189<br />

350 14 104 229 125 274 - - 139 307 115 254<br />

400 16 119 263 143 314 - - 159 351 125 277<br />

450 18 136 299 173 381 - - 182 400 141 311<br />

500 20 163 359 223 491 - - 225 495 189 418<br />

600 24 236 519 338 744 - - 320 704 301 664<br />

700 28 270 595 314 692 - - 273 602 320 704<br />

750 30 - - - - - - 329 725 - -<br />

800 32 346 763 396 873 - - 365 804 428 944<br />

900 36 432 951 474 1043 - - 495 1089 619 1362<br />

1000 40 513 1130 600 1321 - - 583 1282 636 1399<br />

42 - - - - - - 687 1512 - -<br />

44 - - - - - - 763 1680 - -<br />

1200 48 643 1415 885 1948 - - 861 1896 813 1789<br />

- not available<br />

With transmitter MAG 5000 and MAG 6000 <strong>com</strong>pact, weight is increased by approximately 0.8 kg (1.8 lbs), with MAG 6000 I, weight is increased by 5.5 kg<br />

(12.1 lb).<br />

4/63<br />

4

4<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

MAG 3100<br />

■ Overview<br />

The <strong>SITRANS</strong> F M MAG 3100 is an electromagnetic flow sensor<br />

in a large variety that meets the demands of almost every flow<br />

application.<br />

■ Benefits<br />

• Wide range of sizes: DN 15 to DN 2000 (½” to 78”)<br />

• Wide pressure range: PN 6 to PN 100<br />

ANSI Class 150 / 300, AS 2129 / AS 4087. On request up to<br />

690 bar (10000 psi)<br />

• Wide range of electrode and liner material to fit even the most<br />

extreme process media<br />

• Fully welded construction provides a ruggedness that suits<br />

the toughest applications and environments<br />

• Easy <strong>com</strong>missioning, the SENSORPROM unit automatically<br />

updates settings.<br />

• Designed to allow patented <strong>SITRANS</strong> F M in-situ verification<br />

using the SENSORPROM fingerprints.<br />

■ Application<br />

The main applications of the <strong>SITRANS</strong> F M electromagnetic flow<br />

sensors can be found in the following fields:<br />

• Process industry<br />

• Chemical industry<br />

• Steel industry<br />

• Mining<br />

• Utility<br />

• Power generation & distribution<br />

• Oil & gas / HPI<br />

• Water & waste water<br />

4/64<br />

Siemens FI 01 · 2009<br />

©SiemensAG2008<br />

■ Design<br />

• Compact or remote mounting possible<br />

• Easy “plug & play“ field changeability of transmitter<br />

• Ex ATEX and CSA/FM versions<br />

• High temperature sensor for applications with temperatures<br />

up to 180 °C (356 °F)<br />

• Approvals for PTB, OIML R75 and OIML R117<br />

• Meets EEC directives: PED, 97/23/EC pressure directive for<br />

EN1092-1 flanges<br />

• Build-in length according to ISO 13359<br />

• Onsite or factory upgrade to IP68/NEMA 6P of a standard sensor.<br />

■ Mode of operation<br />

The flow measuring principle is based on Faraday’s law of electromagnetic<br />

induction were the sensor converts the flow into an<br />

electrical voltage proportional to the velocity of the flow.<br />

■ Integration<br />

The <strong>com</strong>plete flowmeter consists of a flow sensor and an associated<br />

transmitter MAG 5000, 6000 and 6000 I.<br />

The flexible <strong>com</strong>munication concept USM II simplifies integration<br />

and update to a variety of fieldbus systems such as HART,<br />

FOUNDATION Fieldbus H1, DeviceNet, PROFIBUS DP and PA,<br />

MODBUS RTU/RS485.

■ Technical specifications<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

Version MAG 3100 MAG 3100 HT (High Temperature) MAG 3100 P<br />

Nominal size DN 15 ... DN 2000 (½” ... 78“) DN 15 … DN 300 (½“ ... 12“) DN 15 … DN 300 (½“ ... 12“)<br />

Measuring principle electromagnetic induction<br />

Excitation frequency • DN 15 ... 65 (½“ … 2½”): 12.5 Hz<br />

• DN 80 ... 150 (3” ... 6”): 6.25 Hz<br />

Process connection<br />

• DN 200 ... 1200 (8” ... 48”): 3.125 Hz<br />

• DN 1400 ... 2000 (54” ... 78”):<br />

1.5625 Hz<br />

Flanges EN 1092-1, raised face<br />

(EN 1092-1, DIN 2501 & BS 4504 have<br />

the same mating dimensions)<br />

Rated operation conditions<br />

Ambient temperature (conditions<br />

also dependent on<br />

liner characteristiques)<br />

• DN 65 ... 2000 (2½“ … 48”): PN 6<br />

(87 psi)<br />

• DN 200 ... 2000 (8“ … 48“): PN 10<br />

(145 psi)<br />

• DN 65 ... 2000 (2½“ … 78“): PN 16<br />

(232 psi)<br />

• DN 200 ... 600 (8“ … 24”): PN 25<br />

(362 psi)<br />

• DN 15 ... 600 (½“ … 24”): PN 40<br />

(580 psi)<br />

• DN 50 ... 300 (2“ … 12“): PN 63<br />

(913 psi)<br />

• DN 25 ... 300 (1“ … 12“): PN 100<br />

(1450 psi)<br />

ANSI B16.5 (~BS 1560), raised face<br />

• ½” ... 24”: Class 150 (20 bar<br />

(290 psi))<br />

• ½” ... 24”: Class 300 (50 bar<br />

(725 psi))<br />

AWWA C-207, flat face 28” ... 78”:<br />

Class D (10 bar)<br />

AS 2129, raised face ½” ... 48”:<br />

Table E<br />

AS 4087, raised face:<br />

• PN 16 (DN 50 ... 1200, 16 bar<br />

(232 psi))<br />

• PN 21 (DN 50 ... 600, 21 bar<br />

(304 psi))<br />

• PN 35 (DN 50 ... 600, 35 bar<br />

(508 psi))<br />

Other flanges and pressure ratings on<br />

request<br />

• DN 15 ... 65 (½“ … 2½”): 12.5 Hz<br />

• DN 80 ... 150 (3” ... 6”): 6.25 Hz<br />

• DN 200 ... 300 (8” ... 12”): 3.125 Hz<br />

EN 1092-1, raised face<br />

(EN 1092-1, DIN 2501 & BS 4504 have<br />

the same mating dimensions)<br />

• DN 15 ... 300 (½“ … 12”): PN 40<br />

(580 psi)<br />

• DN 65 ... 300 (2½“ … 12”): PN 16<br />

(232 psi)<br />

• DN 200 ... 300 (8“ … 12“): PN 10<br />

(145 psi)<br />

• DN 200 ... 300 (8“ … 12”): PN 25<br />

(362 psi)<br />

ANSI B16.5 (~BS 1560), raised face:<br />

• ½” ... 12”: Class 150 (20 bar<br />

(290 psi))<br />

• ½” ... 12”: Class 300 (50 bar<br />

(725 psi))<br />

AS 2129, raised face ½” ... 12”:<br />

Table E<br />

Other flanges and pressure ratings on<br />

request<br />

Siemens FI 01 · 2009<br />

MAG 3100<br />

• DN 15 ... 65 (½“ … 2½”): 12.5 Hz<br />

• DN 80 ... 150 (3” ... 6”): 6.25 Hz<br />

• DN 200 ... 300 (8” ... 12”): 3.125 Hz<br />

EN 1092-1, raised face<br />

(EN 1092-1, DIN 2501 & BS 4504 have<br />

the same mating dimensions)<br />

• DN 15 ... 50 (½“ … 2”): PN 40<br />

(580 psi)<br />

• DN 65 ... 300 (2½“ … 12”): PN 16<br />

(232 psi)<br />

• DN 200 ... 300 (8“ … 12“): PN 10<br />

(145 psi)<br />

ANSI B16.5 (~BS 1560), raised face<br />

• ½” ... 12”: Class 150 (20 bar<br />

(290 psi))<br />

• Sensor -40 … +100 ºC (-40 … +212 °F) -40 … +100 ºC (-40 … +212 °F) -40 … +100 ºC (-40 … +212 °F)<br />

• Sensor ATEX -20 … +60 ºC (-4 … +140 °F) for up to 150 °C (302 °F) temperature<br />

of medium:<br />

-20 … +60 ºC (-4 … +140 °F)<br />

• With <strong>com</strong>pact transmitter<br />

MAG 5000/6000<br />

• With <strong>com</strong>pact transmitter<br />

MAG 6000 I<br />

• With <strong>com</strong>pact transmitter<br />

MAG 6000 I Ex d<br />

©SiemensAG2008<br />

for 150 ... 180 °C (302 ... 356 °F)<br />

temperature of medium:<br />

-20 … +50 ºC (-4 … +122 °F)<br />

-20 … +60 ºC (-4 … +140 °F)<br />

-20 … +50 ºC (-4 … +122 °F) -20 … +50 ºC (-4 … +122 °F) -20 … +50 ºC (-4 … +122 °F)<br />

-20 … +60 ºC (-4 … +140 °F) -20 … +60 ºC (-4 … +140 °F) -20 … +60 ºC (-4 … +140 °F)<br />

-10 … +60 ºC (14 … 140 °F) -10 … +60 ºC (14 … 140 °F) -10 … +60 ºC (14 … 140 °F)<br />

4/65<br />

4

4<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

MAG 3100<br />

Version MAG 3100 MAG 3100 HT (High Temperature) MAG 3100 P<br />

Operating pressure<br />

Operating pressure [abs.<br />

bar] (maximum operating<br />

pressure decreases with<br />

increasing operating temperature<br />

and with stainless steel<br />

flanges)<br />

4/66<br />

Siemens FI 01 · 2009<br />

• Neoprene 0.01 ... 100 bar<br />

(0.15 ... 1450 psi)<br />

• EPDM 0.01 ... 40 bar (0.15 ... 580 psi)<br />

• Linatex ® 0.01 ... 40 bar<br />

(0.15 ... 580 psi)<br />

• Ebonite 0.01 ... 100 bar<br />

(0.15 ... 1450 psi)<br />

• PTFE (DN ≤ 300, 0.3 ... 50 bar/<br />

≤ 12“, 4 ... 725 psi)<br />

(350 ≤ DN ≤ 600/14“ ≤ DN ≤ 24“)<br />

0.3 ... 40 bar (4 ... 580 psi)<br />

• PFA<br />

- DN 25 ... 100 (1“ … 4”):<br />

0.01 ... 50 bar (0.15 ... 725 psi)<br />

Enclosure rating IP67/NEMA 4X/6 to EN 60529, 1 mH 2 O<br />

for 30 min<br />

Option: IP68/NEMA 6P to<br />

EN 60529,10 mH 2O cont. (no ATEX)<br />

• PTFE Teflon<br />

- DN 15 ... 300 (½“ … 12”)<br />

(130/180 °C (266 °F/356ºF)):<br />

0.3/0.6 ... 50 bar (4/8 ... 725 psi)<br />

(180 ºC (356 ºF) PTFE has factory<br />

mounted grounding SS rings type E<br />

& SS terminal box)<br />

• PFA<br />

- DN 25 ... 100 (1“ … 4”):<br />

0.01 ... 50 bar (0.15 ... 725 psi)<br />

IP67/NEMA 4X/6 to EN 60529, 1 mH 2 O<br />

for 30 min<br />

Option: IP68/NEMA 6P to<br />

EN 60529,10 mH 2O cont. (no ATEX)<br />

Pressure drop at 3 m/s As straigth pipe<br />

Test pressure 1.5 x PN (where applicable)<br />

Mechanical load • 18 ... 1000 Hz random in x, y z, directions<br />

for 2 hours according to<br />

EN 60068-2-36<br />

• Sensor: 3.17 grms<br />

• Sensor with <strong>com</strong>pact MAG 5000/<br />

6000 mounted transmitter: 3.17 grms<br />

• Sensor with <strong>com</strong>pact MAG 6000 I/<br />

6000 I Ex mounted transmitter:<br />

1.14 grms<br />

• EPDM -10 … +70 °C (14 … 158 °F)<br />

• Linatex ® (rubber) -40 … +70 °C<br />

(-40 … +158 °F) (for temperatures<br />

below -20 °C (-4 °F) AISI 304 or 316<br />

flanges must be used)<br />

• Ebonite 0 … 95 °C (32 … 203 °F)<br />

• PTFE -20 … +100 °C (-4 … +212 °F)<br />

• PFA -20 … +100 °C (-4 … +212°F)<br />

• 18 ... 1000 Hz random in x, y z, directions<br />

for 2 hours according to<br />

EN 60068-2-36<br />

• Sensor: 3.17 grms<br />

• Sensor with <strong>com</strong>pact MAG 5000/<br />

6000 mounted transmitter: 3.17 grms<br />

• Sensor with <strong>com</strong>pact MAG 6000 I/<br />

6000 I Ex mounted transmitter:<br />

1.14 grms<br />

• PTFE -20 … +180 °C (-4 ... +356 °F)<br />

Factory mounted grounding rings<br />

type E and SS terminal box. Can only<br />

be used with remote transmitter.<br />

• PFA -20 … +150 °C (-4 … +300 °F)<br />

• PTFE Teflon<br />

- DN 15 ... 300 (½“ … 12”) :<br />

0.3 ... 40 bar (4 ... 580 psi)<br />

• PFA<br />

- DN 15 ... 100 (1“ … 4”):<br />

0.01 ... 50 bar (0.15 ... 725 psi)<br />

IP67/NEMA 4X/6 to EN 60529, 1 mH 2 O<br />

for 30 min<br />

Option: IP68/NEMA 6P to EN 60529,<br />

10 mH 2O cont. (no ATEX)<br />

• 18 ... 1000 Hz random in x, y z, directions<br />

for 2 hours according to<br />

EN 60068-2-36<br />

• Sensor: 3.17 grms<br />

• Sensor with <strong>com</strong>pact MAG 5000/<br />

6000 mounted transmitter: 3.17 grms<br />

• Sensor with <strong>com</strong>pact MAG 6000 I/<br />

6000 I Ex mounted transmitter:<br />

1.14 grms<br />

Temperature of medium • Neoprene 0 … +70 °C (32 … 158 °F) • PTFE -20 … +130 °C (-4 … +266 °F) • PTFE -20 … +130 °C (-4 … +266 °F)<br />

EMC 89/336 ECC 89/336 ECC 89/336 ECC<br />

Design<br />

Weight See dimensional drawings<br />

Flange and housing material Carbon steel ASTM A 105, with corrosion<br />

res<strong>ista</strong>nt two <strong>com</strong>ponent epoxy<br />

coating (min. 150 µm)<br />

or<br />

AISI 304 (1.4301) flanges and carbon<br />

steel housing, with corrosion res<strong>ista</strong>nt<br />

two <strong>com</strong>ponent epoxy coating (min.<br />

150 µm)<br />

or<br />

AISI 316 L (1.4404) flanges and housing,<br />

polished<br />

Measuring pipe material AISI 304 (1.4301)<br />

(AISI 316L (1.4404) flanges and housing,<br />

polished has measuring pipe of<br />

AISI 316L (1.4435))<br />

Electrode material • AISI 316 Ti (1.4571)<br />

• Hastelloy C276 (PFA: Hastelloy C22)<br />

• Platinum/Iridium,<br />

• Titanium<br />

• Tantalum<br />

Grounding Electrode material Material as measuring electrodes:<br />

Exceptions - see ordering data<br />

©SiemensAG2008<br />

Carbon steel ASTM A 105, with corrosion<br />

res<strong>ista</strong>nt two <strong>com</strong>ponent epoxy<br />

coating (min. 150 µm)<br />

or<br />

AISI 304 (1.4301) flanges and carbon<br />

steel housing, with corrosion res<strong>ista</strong>nt<br />

two <strong>com</strong>ponent epoxy coating (min.<br />

150 µm)<br />

or<br />

AISI 316 L (1.4404) flanges and housing,<br />

polished<br />

AISI 304 (1.4301)<br />

(AISI 316L (1.4404) flanges and housing,<br />

polished has measuring pipe of<br />

AISI 316L (1.4435))<br />

• AISI 316 Ti (1.4571)<br />

• Hastelloy C276 (PFA: Hastelloy C22)<br />

• Platinum/Iridium,<br />

• Titanium<br />

• Tantalum<br />

• PFA -20 … +150 °C (-4 … +300 ºF)<br />

Carbon steel ASTM A 105, with corrosion<br />

res<strong>ista</strong>nt two <strong>com</strong>ponent epoxy<br />

coating (min. 150 µm)<br />

AISI 304 (1.4301)<br />

Hastelloy C276 (PFA: Hastelloy C22)<br />

No grounding electrodes No grounding electrodes

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

Version MAG 3100 MAG 3100 HT (High Temperature) MAG 3100 P<br />

Design (continued)<br />

Terminal box (remote version<br />

only)<br />

• Standard Fibre glass-reinforced<br />

polyamide<br />

• Option Stainless steel AISI 316<br />

(1.4436)<br />

• Ex ATEX (remote version only) Stainless<br />

steel AISI 316 (1.4436)<br />

Cable entries • Remote installation 2 x M20 or<br />

2 x ½ NPT<br />

Certificates and approvals<br />

• Compact installation<br />

- MAG 5000/MAG 6000: 4 x M20 or<br />

4 x ½”NPT<br />

- MAG 6000 I: 2 x M25<br />

(for supply/output)<br />

- MAG 6000 I Ex. d: 2 x M20 (for supply/output)<br />

Technical specification for transmitter - please see transmitter pages.<br />

• Stainless steel AISI 316 (1.4436)<br />

• Ex ATEX (remote version only) Stainless<br />

steel AISI 316 (1.4436)<br />

• Remote installation 2 x M20 or<br />

2 x ½ NPT<br />

Siemens FI 01 · 2009<br />

MAG 3100<br />

• Standard Fibre glass-reinforced<br />

polyamide<br />

• Option Stainless steel AISI 316<br />

(1.4436)<br />

• Ex ATEX (remote version only) Stainless<br />

steel AISI 316 (1.4436)<br />

• Remote installation 2 x M20 or<br />

2 x ½ NPT<br />

• Compact installation<br />

- MAG 5000/MAG 6000: 4 x M20 or<br />

4 x ½”NPT<br />

- MAG 6000 I: 2 x M25<br />

(for supply/output)<br />

- MAG 6000 I Ex. d: 2 x M20 (for supply/output)<br />

Conforms to PED – 97/23 EC, CRN PED – 97/23 EC, CRN PED – 97/23 EC, CRN<br />

Material certificate<br />

EN 10204 3.1<br />

On request On request Pipe and flange certificate available as<br />

option<br />

Ex approvals ATEX 2G D sensor<br />

• DN 15 ... 300: EEx d e ia IIC T4 - T6<br />

• DN 350 ... 2000 EEx e ia IIC T4 - T6<br />

Non ATEX sensors<br />

• FM Class 1 Div 2<br />

• CSA Class 1, Div 2<br />

Drinking water approvals EPDM lining:<br />

Custody transfer (CT)<br />

(≤ DN2000)<br />

(only together with<br />

MAG 5000/6000 CT), order<br />

as special<br />

• WRAS (WRc, BS6920 cold water, GB)<br />

• ACS listed (F)<br />

• DVGW W270 (D)<br />

• Belaqua (B)<br />

Cold water pattern approval - DANAK<br />

TS 22.36.001, PTB (Denmark and Germany)<br />

Heat meter pattern approval -<br />

OIML R 75 (Denmark)<br />

Hot water pattern approval - PTB<br />

(Germany)<br />

Other media than water - OIML R 117<br />

(Denmark)<br />

©SiemensAG2008<br />

ATEX 2G D sensor<br />

• DN 15 ... 300: EEx d e ia IIC T3 - T6<br />

Non ATEX sensors<br />

• FM Class 1 Div 2<br />

• CSA Class 1, Div 2<br />

Cold water pattern approval - DANAK<br />

TS 22.36.001, PTB (Denmark and Germany)<br />

Heat meter pattern approval -<br />

OIML R 75 (Denmark)<br />

Hot water pattern approval - PTB<br />

(Germany)<br />

Other media than water - OIML R 117<br />

(Denmark)<br />

ATEX 2G D sensor<br />

• DN 15 ... 300: EEx d e ia IIC T3 - T6<br />

Non ATEX sensors<br />

• FM Class 1 Div 2<br />

• CSA Class 1, Div 2<br />

Cold water pattern approval - DANAK<br />

TS 22.36.001, PTB (Denmark and Germany)<br />

Heat meter pattern approval -<br />

OIML R 75 (Denmark)<br />

Hot water pattern approval - PTB<br />

(Germany)<br />

Other media than water - OIML R 117<br />

(Denmark)<br />

4/67<br />

4

4<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

MAG 3100<br />

Selection and Ordering data Order No.<br />

Sensor <strong>SITRANS</strong> F M MAG 3100 7 M E 6 3 1 0 -<br />

Diameter<br />

DN 15 (½“) (PTFE liner only) 1 V<br />

DN 25 (1“) 2 D<br />

DN 40 (1½“) 2 R<br />

DN 50 (2“) 2 Y<br />

DN 65 (2½“) 3 F<br />

DN 80 (3“) 3 M<br />

DN 100 (4“) 3 T<br />

DN 125 (5“) 4 B<br />

DN 150 (6“) 4 H<br />

DN 200 (8“) 4 P<br />

DN 250 (10“) 4 V<br />

DN 300 (12“) 5 D<br />

DN 350 (14“) 5 K<br />

DN 400 (16“) 5 R<br />

DN 450 (18“) 5 Y<br />

DN 500 (20“) 6 F<br />

DN 600 (24“) 6 P<br />

DN 700 (28“) 6 Y<br />

DN 750 (30“) 7 D<br />

DN 800 (32“) 7 H<br />

DN 900 (36“) 7 M<br />

DN 1000 (40“) 7 R<br />

DN 1050 (42“) 7 U<br />

DN 1100 (44“) 7 V<br />

DN 1200 (48“) 8 B<br />

DN 1400 (54“) 8 F<br />

DN 1500 (60“) 8 K<br />

DN 1600 (66“) 8 P<br />

DN 1800 (72“) 8 T<br />

DN 2000 (78“) 8 Y<br />

Flange norm and pressure rating<br />

to EN 1092-1<br />

PN 6 (DN 65 ... 2000 (2½“ ... 78“)) A<br />

PN 10 (DN 200 ... 2000 (8“ ... 78“)) B<br />

PN 16 (DN 65 ... 1200 (2½“ ... 48“)) C<br />

PN 16, non PED (DN 700 ... 2000 (28“ ... 78“))<br />

D<br />

PN 25 (DN 200 ... 600 (8“ ... 24“)) E<br />

PN 40 (DN 15 ... 600 (½“ ... 24“)) F<br />

PN 63 (DN 50 ... 300 (2“ ... 12“)), not PTFE or PFA G<br />

PN 100 (DN 25 ... 300 (1“ ... 12“)), not PTFE or PFA H<br />

to ANSI B16.5<br />

Class 150 (½“ ... 24“) J<br />

Class 300 (½“ ... 24“) K<br />

to AWWA C207<br />

Class D (28“ ... 78“) L<br />

to AS<br />

2129, table E M<br />

4087, PN 16 (DN 50 ... 1200 (2“ ... 48“)) N<br />

4087, PN 21 (DN 50 ... 600 (2“ ... 24“)) P<br />

4087, PN 35 (DN 50 ... 600 (2“ ... 24“)) Q<br />

Flange material<br />

Carbon steel flanges ASTM A 105 1<br />

Stainless steel flanges, AISI 304 2<br />

Stainless steel flanges and sensor body, AISI 316L, 3<br />

polished<br />

Please also see www.siemens.<strong>com</strong>/<strong>SITRANS</strong>Fordering<br />

for practical examples of ordering<br />

4/68<br />

Siemens FI 01 · 2009<br />

©SiemensAG2008<br />

77777 -7777<br />

Selection and Ordering data Order No.<br />

Sensor <strong>SITRANS</strong> F M MAG 3100 7 M E 6 3 1 0 -<br />

Liner material<br />

Neoprene 1<br />

EPDM 2<br />

PTFE (DN ≤ 300, PN ≤ 50 bar / ≤ 12“, PN ≤ 725 psi),<br />

PTFE (350 ≤ DN ≤ 600, PN ≤ 40 bar /<br />

14“ ≤ DN ≤ 24“, PN ≤ 580 psi)<br />

3<br />

Ebonite 4<br />

Linatex (PN ≤ 40 bar (580 psi) DN ≤ 600 (24“)) 5<br />

PFA (DN 25, 50, 80, 100 (1", 2", 3", 4"))<br />

(PN ≤ 40 bar (580 psi))<br />

7<br />

Electrode material<br />

(Grounding electrodes not for PTFE/PFA liner or<br />

Pressure PN 100)<br />

AISI 316 TI 1<br />

Hastelloy C276 (PFA liner: Hastelloy C22) 2<br />

Platinum (DN ≤ 300/12") (no grounding electrodes) 3<br />

Titanium (not PFA liner) 4<br />

Tantalum (DN ≤ 600 (24")) (no grounding electrodes) 5<br />

Transmitter with display<br />

Sensor for remote transmitter (Order transmitter sep.) A<br />

Sensor ATEX 2G D for remote transmitter (Order<br />

transmitter separately)<br />

B<br />

MAG 6000 I, Alu.18 ... 90 V DC, 115 ... 230 V AC C<br />

MAG 6000 I Alu. 18 ... 30 V DC, ATEX 2G D D<br />

MAG 6000 I Alu. 115 ... 230 V, ATEX 2G D E<br />

MAG 6000 Polyamid, 11… 30 V DC / 11…24 V AC H<br />

MAG 6000, Polyamid, 115/230 V AC J<br />

MAG 5000, Polyamid, 11… 30 V DC / 11…24 V AC K<br />

MAG 5000, Polyamid, 115/230 V AC L<br />

Communication<br />

No <strong>com</strong>munication, add-on possible A<br />

HART B<br />

PROFIBUS PA Profile 3<br />

F<br />

(only MAG 6000/MAG 6000 I)<br />

PROFIBUS DP Profile 3 (no ATEX)<br />

G<br />

(only MAG 6000/MAG 6000 I)<br />

MODBUS RTU/RS 485 (no ATEX)<br />

E<br />

(only MAG 6000/MAG 6000 I)<br />

FOUNDATION Fieldbus H1<br />

J<br />

(only MAG 6000/MAG 6000 I)<br />

Cable glands/terminal box<br />

77777 -7777<br />

Metric: Polyamid terminal box or 6000I <strong>com</strong>pact 1<br />

½" NPT: Polyamid terminal box or 6000I <strong>com</strong>pact 2<br />

Metric: SS terminal box (mandatory for Stainless<br />

steel MAG 6000 Transmitter)<br />

3<br />

½" NPT: SS terminal box (mandatory for Stainless<br />

steel MAG 6000 Transmitter)<br />

4

Selection and Ordering data Order code<br />

Additional information<br />

Please add “-Z“ to Order No. and specify Order<br />

code(s) and plain text.<br />

Customer specific converter setup Y20<br />

Tag name plate, stainless steel fixed with SS wire<br />

(add plain text)<br />

Please use online Product selector to get latest updates.<br />

Product selector link:<br />

www.pia-selector.automation.siemens.<strong>com</strong><br />

Y17<br />

Tag name plate, plastic (self adhesive) Y18<br />

Factory certificate according to EN 10204-2.1 C15<br />

Factory certificate according to EN 10204-2.2 C14<br />

Sensor cables wired (specify cable order no.) Y40<br />

Sensor for remote transmitter's junction box potted to<br />

IP68 with wired cable (specify cable order no.)<br />

(no ATEX)<br />

Y41<br />

Other postproduction requirements (add desired text) Y99<br />

Description Order No.<br />

Potting kit for terminal box<br />

of <strong>SITRANS</strong> F M sensors for<br />

IP68/NEMA 6P (Not ATEX)<br />

FDK-085U0220<br />

MAG 5000/6000 transmitters and sensors are packed in separate<br />

boxes, the final assembly takes place during installation at<br />

the customer's place. MAG 6000 I/MAG 6000 I ATEX 2G D transmitters<br />

and sensors are delivered <strong>com</strong>pact mounted from factory.<br />

Communication module will be pre-mounted in the transmitter.<br />

©SiemensAG2008<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

Siemens FI 01 · 2009<br />

MAG 3100<br />

4/69<br />

4

4<br />

<strong>SITRANS</strong> F <strong>flowmeters</strong><br />

<strong>SITRANS</strong> F M<br />

MAG 3100<br />

Selection and Ordering data Order No.<br />

Sensor <strong>SITRANS</strong> F M<br />

MAG 3100 HT (High Temperature) 7 M E 6 3 2 0 -<br />

Diameter<br />

DN 15 (½“) 1 V<br />

DN 25 (1“) 2 D<br />

DN 40 (1½“) 2 R<br />