Benefits of CRAC Supply Control

Summary

A Fortune 50 Telecommunications provider (the Client) wanted to demonstrate the differences between the Return Air Temperature Control and Supply Air Temperature Control, and quantify the benefits of switching to Supply Air Control system. The Client’s Ashburn, VA contained six legacy data centers with the original Return control systems. Purkay Labs’ On-Site Assessment Service was used to benchmark the changes to the data hall environment, and was used to justify the benefits of implementing the change in the Client’s other legacy facilities.

Case Study Highlights

Client

Fortune 50 Telecom

Tier 4 Facility in Ashburn, VA

Facility

Size: 15,000 square feet, Raised Floor

Cabinets: 384 Cabinets

Load: 920 kW It Load

Cooling: 1010 Cooling Capacity

Electricity Cost: 6¢/kWh

Project Goals:

The Client wanted to benchmark the effect of changing from Return Air Control to Supply Air Control in order to implement change throughout their different legacy facilities

Tools Used

Key Results

Reduced electricity bill by $10,238 annually

Increase average inlet temperature by 6°F

Lowered PUE by .03

Increase energy efficiency by 4.8°F

Introduction

QuickScan Mode

Interactive Data Hall Program

A Fortune 50 Telecommunications provider (the Client) wanted to demonstrate the differences between the Return Air Temperature Control and Supply Air Temperature Control, and quantify the benefits of switching to Supply Air Control System. The Client’s Ashburn, VA contained six legacy data centers with the original Return control systems. Purkay Labs’ On-Site Assessment service was used to benchmark the changes to the Data Hall Environment, and was used to justify the benefits of implementing the change in the Client’s other legacy facilities.

The Project

In May 2017, Purkay Labs provided five AUDIT-BUDDY™ systems to measure temperature, humidity and dewpoint at each of the 384 cabinets. This took approximately 4 hours, including set-up time. Purkay Labs captured and imported this data into a custom Interactive Data Hall program.

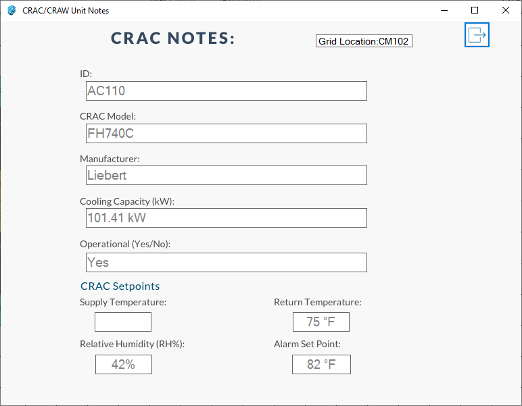

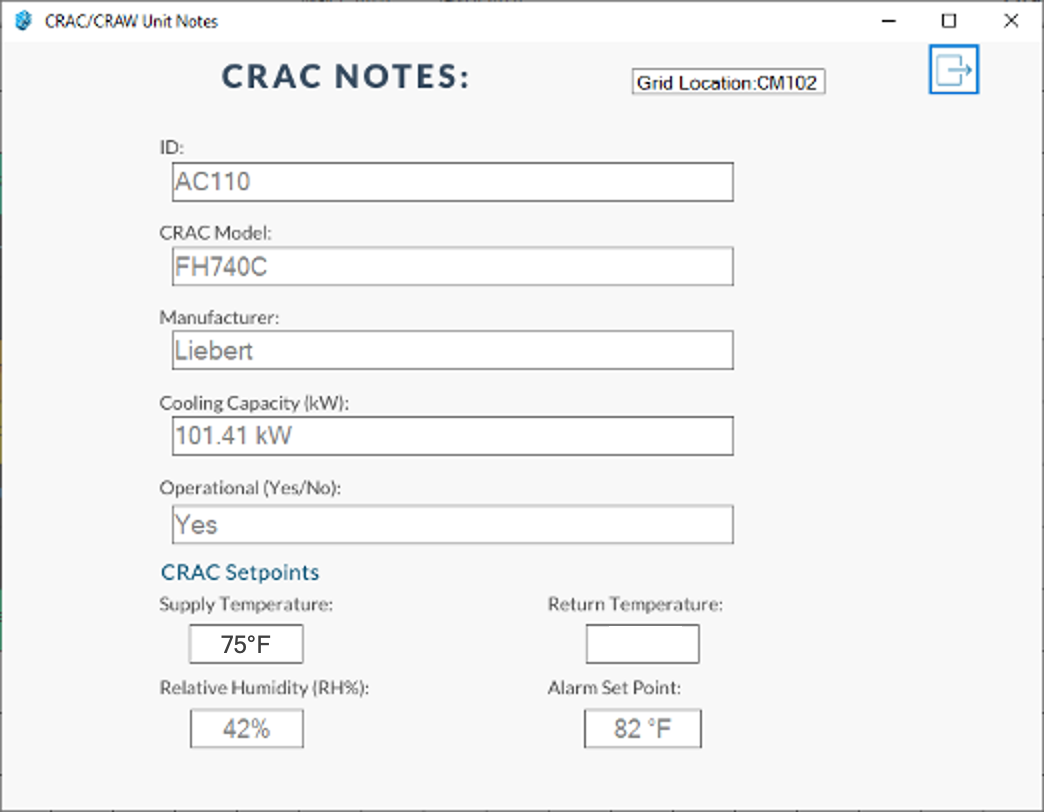

After the first benchmark assessment, Purkay Labs founded that there was a significant difference between the average inlet temperature (67.7°F) and the CRAC set points (75°F).

This is significant for two reasons:

1) The CRAC Units used a single sensor point to control & respond to the ambient temperature. This assumes that there is little to no variation between the average inlet temperature and the CRAC sensor. The On-Site Assessment Service showed that there was both variation across the aisles as well as in front of the CRAC Unit.

2) The Return Air Control assumes a closed loop system, where the supplied air goes to the server and directly back to the CRAC unit. In this case, the fact that the average inlet temperatures were significantly lower than the return temperatures showed that cold air was mixing and diluting the closed loop system. August 2017 Results- The “After” View

Before View - Aisle Average Temp of 68.4°F

Return Control Set Point: 75°F

After View - Aisle Average Temp 73.6°F

Supply Control Set Point: 75°F

Purkay Labs first assessment showed that the Return Air Control was not functioning as designed.

Between June and July, the Client switched to the Supply Air Control features, and in August, Purkay Labs returned to benchmark the facility again. The Client maintained the same 75°F set point for the Supply Air Control. Purkay Labs found that the average inlet temperature increased from 67.7°F to 72°F, and several areas that fell below ASHRAE recommended standards had significantly improved.

Conclusion:

The Client was able to use data collected through the On-Site Assessment to make an informed decision to change the CRAC Control system. The initial data showed that the Return Air Temperature Control system was not working as intended, and justified the switch. The second set of data proved that the Supply Air Temperature Control was more efficient, allowed the Data Center Manager more control over the environment. Ultimately, the Client was able to add more load to the Data Hall and still reduce the PUE. This resulted in a $10,238 savings annually. The Client was able to implement the same changes throughout the facility.

Key Take-Aways

Gaps in Coverage

The Client had a comprehensive BMS system and permanent sensors on every third rack. However, there was not enough information to capture the temperature variations in the areas without permanent sensors; in between inlet sensors and the hot aisles.

Actionable Data

The Interactive Data Hall program provided a comprehensive baseline for the before & after. Moreover, the Client could easily filter through the data to confirm all temperatures met ASHRAE standards and isolate the sections at risk, like Cabinets BA128-BA32. The Interactive Data Hall allows you to quickly switch between cabinet level data to room temperatures.

Clear Results

The “before” view quickly showed that the room was significantly overcooled, and their was a wide variation between individual cabinets and aisle. This information was crucial in proving the need to switch to a “supply control” to mitigate inlet temperature variation. Once the “after” view was complete, the success was clearly visible, as the color scale was more uniform.

The Importance of Switching to Supply Control

This case study proves that switching the supply control is the most efficient way to optimize the cooling system. Before the return control relied on a single sensor to reflect the total room ambient, when in reality the inlet temperatures varied widely. By switching to the supply control, the facility manager can more easily control and respond to temperature variations and influences on mixed cooling.