Variable-Area Flowmeter Device Description - Adinco bv

Variable-Area Flowmeter Device Description - Adinco bv

Variable-Area Flowmeter Device Description - Adinco bv

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

www.heinrichs-mt.nl<br />

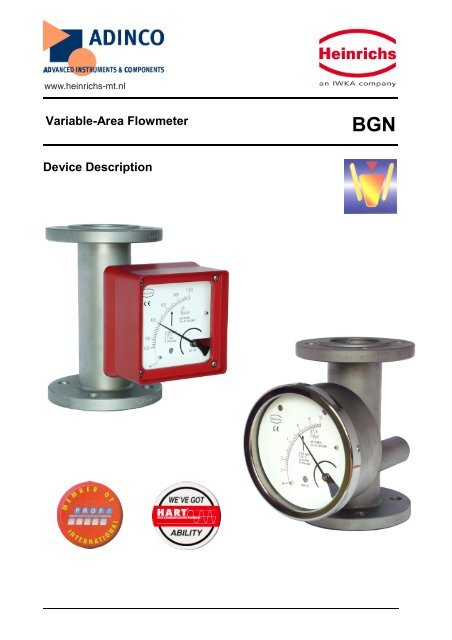

<strong>Variable</strong>-<strong>Area</strong> <strong>Flowmeter</strong><br />

BGN<br />

<strong>Device</strong> <strong>Description</strong>

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

Contents<br />

1 IDENTIFICATION ............................................................................................................................................................. 4<br />

1.1 Supplier/manufacturer .............................................................................................................................4<br />

1.2 Product type ..............................................................................................................................................4<br />

1.3 Product name ............................................................................................................................................4<br />

1.4 Issue date ...................................................................................................................................................4<br />

1.5 Version no..................................................................................................................................................4<br />

2 APPLICATIONS ............................................................................................................................................................... 4<br />

3 OPERATIONAL MODE AND SYSTEM DESIGN.............................................................................................................. 4<br />

3.1 Measuring principle..................................................................................................................................4<br />

3.2 System design ............................................................................................................................................4<br />

4 INPUT ........................................................................................................................................................................ 4<br />

4.1 Measured variable ....................................................................................................................................4<br />

4.2 Measuring range (lower-range and upper-range value)........................................................................4<br />

4.3 Measuring range table..............................................................................................................................5<br />

5 OUTPUT ........................................................................................................................................................................ 6<br />

5.1 Binary output ............................................................................................................................................6<br />

5.1.1 KEI 1 or KEI 2 limit transducers..........................................................................................................6<br />

5.1.2 KEM 1 or KEM 2 limit transducers (special version) ..........................................................................6<br />

5.2 Analog output with the ES magneto-electric transmitter......................................................................6<br />

5.3 Analog output with the KINAX 3W2 angle-of-rotation transmitter ....................................................6<br />

6 CHARACTERISTIC VALUES........................................................................................................................................... 6<br />

6.1 Measuring accuracy..................................................................................................................................6<br />

6.1.1 Reference conditions ............................................................................................................................6<br />

6.1.2 Measured error......................................................................................................................................6<br />

6.1.3 Repeatability.........................................................................................................................................6<br />

6.2 Influence of ambient temperature ...........................................................................................................6<br />

6.3 Influence of fluid temperature .................................................................................................................6<br />

7 CONDITIONS OF USE ..................................................................................................................................................... 6<br />

7.1 Mounting requirements............................................................................................................................6<br />

7.1.1 Mounting/start-up .................................................................................................................................7<br />

7.1.2 <strong>Device</strong> settings......................................................................................................................................7<br />

7.1.3 Adjusting the limit transducer ..............................................................................................................7<br />

7.1.4 Operation in hazardous areas................................................................................................................8<br />

7.2 Ambient conditions ...................................................................................................................................8<br />

7.2.1 Ambient temperature ranges.................................................................................................................8<br />

7.2.2 Storage temperature..............................................................................................................................8<br />

7.2.3 Climatic category..................................................................................................................................8<br />

7.2.4 Degree of protection .............................................................................................................................8<br />

7.2.5 Shock resistance/vibration resistance ...................................................................................................8<br />

7.2.6 Electromagnetic compatibility..............................................................................................................8<br />

7.3 Fluid conditions.........................................................................................................................................9<br />

7.3.1 Fluid temperature ranges ......................................................................................................................9<br />

7.3.2 Diagrams: Max. ambient temperature based on the fluid temperature for the ES ................................9<br />

7.3.3 Fluid pressure limit.............................................................................................................................10<br />

7.3.4 Inlet and outlet sections ......................................................................................................................10<br />

7.3.5 Physical state ......................................................................................................................................10<br />

7.3.6 Density................................................................................................................................................10<br />

7.3.7 Viscosity.............................................................................................................................................10<br />

Page 2 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

7.3.8 Pressure (for gas measurement)..........................................................................................................10<br />

7.3.9 Pressure loss .......................................................................................................................................10<br />

8 CONSTRUCTION DETAILS........................................................................................................................................... 11<br />

8.1 Type of construction/dimensions ...........................................................................................................11<br />

8.1.1 Aluminum indicator housing ..............................................................................................................11<br />

8.1.2 Dimension drawing for heating connection........................................................................................11<br />

8.1.3 Indicator housing made of stainless steel............................................................................................12<br />

8.2 Weight......................................................................................................................................................12<br />

8.3 Material....................................................................................................................................................13<br />

8.4 Process connection ..................................................................................................................................13<br />

8.5 Magnetic filter .........................................................................................................................................13<br />

8.6 Electrical connection...............................................................................................................................14<br />

8.6.1 Wiring diagram for ES transmitter (signal output 4-20 mA with HART®).......................................14<br />

8.6.2 Wiring diagram for ES transmitter with 4-20 mA output and 2 limit transducers..............................14<br />

8.6.3 Wiring diagram for ES transmitter with 4- 20 mA output, pulse output and limit transducer............15<br />

8.6.4 Wiring diagram for inductive limit transducers..................................................................................15<br />

8.6.5 Wiring diagram for KINAX 3W2 transmitter with 4-20 mA output, 2 wires.....................................16<br />

8.6.6 Wiring diagram for KINAX 3W2 transmitter with 4-20 mA output, 3 wires.....................................16<br />

8.6.7 Wiring diagram for KINAX 3W2 transmitter with 4-20 mA output, 4 wires.....................................17<br />

8.6.8 Wiring diagram for KEM 1 and KEM 2 double-throw microswitches...............................................17<br />

9 INDICATOR UNIT........................................................................................................................................................... 18<br />

10 AUXILIARY POWER...................................................................................................................................................... 18<br />

11 CE MARK ...................................................................................................................................................................... 18<br />

12 ORDER INFORMATION................................................................................................................................................. 18<br />

12.1 Available accessories...............................................................................................................................18<br />

13 STANDARDS AND DIRECTIVES, CERTIFICATES AND APPROVALS........................................................................ 18<br />

14 REPLACEMENT PARTS................................................................................................................................................ 18<br />

15 EXPLODED VIEWS........................................................................................................................................................ 19<br />

15.1 Fitting with measuring element .............................................................................................................19<br />

15.1.1 BGN-.... Standard version..................................................................................................................19<br />

15.1.2 BGN-.... with spring stop...................................................................................................................19<br />

15.1.3 BGN-.... with damping piston.............................................................................................................19<br />

15.1.4 BGN-.... with damping piston and spring stop ...................................................................................20<br />

15.1.5 BGN-.... small measuring ranges........................................................................................................20<br />

15.2 Indicator unit...........................................................................................................................................21<br />

15.2.1 Complete indicator unit, local with scale............................................................................................21<br />

15.2.2 Complete indicator unit with 1 SJ 3,5 N limit transducer...................................................................21<br />

15.2.3 Complete indicator unit with 2 SJ 3,5 N limit transducers .................................................................21<br />

15.2.4 Complete indicator unit with E2 KINAX Ex transmitter....................................................................22<br />

15.2.5 Complete indicator unit with E2 KINAX Ex transmitter and 1 SJ 3,5 N limit transducer .................22<br />

15.2.6 Indicator unit with transmitter type ES Ex HART® ..........................................................................22<br />

16 EC TYPE EXAMINATION CERTIFICATE ...................................................................................................................... 23<br />

17 SALES REPRESENTATIVES ........................................................................................................................................ 28<br />

18 NOTES ...................................................................................................................................................................... 28<br />

Page 3 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

1 Identification<br />

1.1 Supplier/manufacturer<br />

Heinrichs Messtechnik GmbH<br />

Robert-Perthel-Str. 9 ⋅ D-50739 Köln<br />

Phone +49 (221) 49708 - 0<br />

Fax +49 (221) 49708 - 92<br />

Internet: http://www.heinrichs-mt.nl<br />

E-mail: mailto:info@heinrichs-mt.nl<br />

1.2 Product type<br />

<strong>Flowmeter</strong> in all-metal design based on the float principle<br />

1.3 Product name<br />

BGN with subgroups<br />

BGN-S (stainless steel)<br />

BGN-P (PTFE)<br />

BGN-H (Hastelloy)<br />

1.4 Issue date<br />

09/07/2003<br />

1.5 Version no.<br />

2.0<br />

File: BGN_GB_02_eng<br />

2 Applications<br />

The BGN meter is suitable for flow measurement of liquid or<br />

gaseous products in pipes. It shows the current flow rate in<br />

volume or mass per unit in time.<br />

Applications: flow measurement, dosing, monitoring,<br />

adjusting and control of liquid and gaseous products.<br />

The meter’s design makes it ideal for processes under<br />

difficult and adverse operating conditions.<br />

The devices are available with additional electrical<br />

equipment for process monitoring and control.<br />

3 Operational mode and system<br />

design<br />

3.1 Measuring principle<br />

The measuring element consists of a sharp-edged<br />

measuring ring (1) and a conical float (2). A medium flows<br />

from the bottom to the top through the measuring ring, lifting<br />

the float until the buoyancy force (A) and the weight of the<br />

float (Gs) establish equilibrium. As the height of the float<br />

varies, an annular clearance (S) proportional to the flow<br />

appears between the float and the measuring ring. The<br />

height of the float in the measuring ring is a measure of the<br />

flow. The permanent magnet (3) embedded in the float then<br />

transmits this measure to the scale and the optional<br />

electronic evaluators through a magnet tracking indicator<br />

system (4).<br />

3.2 System design<br />

The meter consists of a cylindrical fitting pipe with flange<br />

connections on both sides. For the measuring range from<br />

5 to 50 l/h, a measuring ring is inserted in the tube in which a<br />

conical float can move with vertical freedom. For small<br />

measuring ranges of up to 4–40 l/h, the measuring cell<br />

consists of a conical measuring tube with cylindrical float.<br />

The height of the float resulting from the flow rate is<br />

transmitted in a rotary motion by a built-in permanent<br />

magnet through a magnet tracking indicator system in a<br />

rotation to the pointer axis of the analog indicator unit.<br />

4 Input<br />

4.1 Measured variable<br />

Volume flow<br />

4.2 Measuring range (lower-range and<br />

upper-range value)<br />

The lower-range value is considered 10% of the upper-range<br />

value. Measuring range span: 10-100%<br />

Smallest measuring range: 0.5-5.0 l/h water<br />

Largest measuring range: 8.000-80.000 l/h water (stainless<br />

steel)<br />

Page 4 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

4.3 Measuring range table<br />

Nominal<br />

size (DN)<br />

Measuring<br />

range<br />

Measuring range for<br />

water at 1000 kg/m3<br />

Measuring range for air<br />

at 1.013 bars absolute<br />

pressure<br />

Pressure loss<br />

(mbar)<br />

Remarks<br />

15 A 0.5– 5.0 I/h 0.015 – 0.15 m 3 /h 40 1)+2)<br />

B 1.0 – 10 I/h 0.03 – 0.30 m 3 /h 44 1)+2)<br />

C 1.6 – 16 I/h 0.045 – 0.48 m 3 /h 40 1)+2)<br />

D 2.5 – 25 I/h 0.075 – 0.75 m 3 /h 40 +2)<br />

E 4.0 – 40 I/h 0.13 – 1.3 m 3 /h 40 +2)<br />

F 5.0 – 50 I/h 0.15 – 1.5 m 3 /h 40<br />

G 7.0 – 70 I/h 0.2 – 2.1 m 3 /h 40<br />

H 10 – 100 I/h 0.3 – 3.0 m 3 /h 60<br />

I 16 – 160 I/h 0.5 – 4.6 m 3 /h 60<br />

J 25 – 250 I/h 0.7 – 7.0 m 3 /h 60<br />

K 40 – 400 I/h 1.0 – 11 m 3 /h 70<br />

L 60 – 600 I/h 1.7 – 17 m 3 /h 80<br />

M 100 – 1000 I/h 3 – 30 m 3 /h 60 5)<br />

N 160 - 1600 I/h 4 – 46 m 3 /h 70 5)<br />

P 250 – 2500 I/h 7 – 70 m 3 /h 100 5)<br />

25 A 0.5 – 5.0 I/h 0.015 – 0.15 m 3 /h 40 1)+2)<br />

B 1.0 –10 I/h 0.03 – 0.30 m 3 /h 40 1)+2)<br />

C 1.6 –16 I/h 0.045 – 0.48 m 3 /h 40 1)+2)<br />

D 2.5 – 25 I/h 0.075 – 0.75 m 3 /h 40 +2)<br />

E 4.0 – 40 I/h 0.13 – 1.3 m 3 /h 40 +2)<br />

F 5.0 – 50 I/h 0.15 – 1.5 m 3 /h 40<br />

G 7.0 – 70 I/h 0.2 – 2.1 m 3 /h 40<br />

H 10 – 100 I/h 0.3 – 3.0 m 3 /h 60<br />

I 16 – 160 I/h 0.5 – 4.6 m 3 /h 60<br />

J 25 – 250 I/h 0.7 – 7.0 m 3 /h 60<br />

K 40 – 400 I/h 1.0 – 11 m 3 /h 70<br />

L 60 – 600 I/h 1.7 – 17 m 3 /h 80<br />

M 100 – 1000 I/h 3 – 30 m 3 /h 60<br />

N 160 – 1600 I/h 4 – 46 m 3 /h 70<br />

P 250 – 2500 I/h 7 – 70 m 3 /h 100<br />

Q 400 – 4000 I/h 11 – 110 m 3 /h 240 3)+ 4)<br />

40 P 250 – 2500 I/h 7 – 70 m 3 /h 50 3)<br />

Q 400 – 4000 I/h 11 – 110 m 3 /h 120 3)<br />

R 600 – 6000 I/h 17 – 170 m 3 /h 180 3)<br />

50 Q 400 – 4000 I/h 11 – 110 m 3 /h 80<br />

R 600 – 6000 I/h 17 – 170 m 3 /h 90<br />

S 1000 – 10000 I/h 29 – 290 m 3 /h 110<br />

T 1600 –16000 I/h 46 – 460 m 3 /h 230<br />

U 2500 – 25000 I/h 70 – 700 m 3 /h 500 3)+ 4)<br />

80 T 1600 – 16000 I/h 46 – 460 m 3 /h 70<br />

U 2500 – 25000 I/h 70 – 700 m 3 /h 100<br />

V 4000 – 40000 I/h 110 – 1100 m 3 /h 350<br />

100 V 4000 – 40000 I/h 110 – 1100 m 3 /h 120<br />

W 6000 – 60000 I/h 170 – 1700 m 3 /h 360<br />

X 8000 – 80000 I/h 240 - 2400 m 3 /h 600 3)+ 4)<br />

1) for P version (PTFE), float with tantalic collar, cone of borosilicate glass<br />

measuring range: A 0.7–7.0 l/h, B 1.2–12 l/h, C 2.0–20 l/h<br />

2) gas throttle in S version for gas measurement included in price (pressure loss 200 mbar)<br />

3) not available in P version<br />

4) conversion not possible<br />

5) only in S and H version, only with smaller sealing strip<br />

Page 5 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

5 Output<br />

Various electrical contact makers or transmitters may be<br />

installed in the indicator unit.<br />

5.1 Binary output<br />

Using the segments of the slot-type initiators or the eccentric<br />

discs of the microswitches, any switching point between 10%<br />

and 90% of the flow rate can be set.<br />

5.1.1 KEI 1 or KEI 2 limit transducers<br />

1 or 2 limit transducers,<br />

type SJ 3,5N, make Pepperl+Fuchs<br />

(special switch possible, e.g. SN version)<br />

Safety class: PTB Nr. 99 ATEX 2219 X<br />

PTB Nr. 00 ATEX 2048 X<br />

5.1.2 KEM 1 or KEM 2 limit transducers<br />

(special version)<br />

Double-throw microswitches whose switching point is<br />

activated by a cam plate.<br />

KEM 1 = 1 Double-throw microswitch<br />

KEM 2 = 2 Double-throw microswitches<br />

Maximum make-break capacity:<br />

230 VAC 50/60Hz 6 A<br />

24 VDC 0.5 A<br />

110 VDC 0.2 A<br />

5.2 Analog output with the ES<br />

magneto-electric transmitter<br />

The magneto-electric transmitter is factory-calibrated to the<br />

scale values upon shipment. The signal output is supplied<br />

exclusively in a two-wire connection at 4-20 mA. Normally,<br />

the 4-20 mA signal has the HART® protocol; alternatively it<br />

can have PROFIBUS PA.<br />

Additional options: 2 limit values, alternatively 1 limit value<br />

and 1 pulse output<br />

The signal output and the limit values can be configured<br />

using a HART® modem operating on the following<br />

configuration programs: SensorPort from Bopp & Reuther,<br />

PDM from Siemens or AMS from Rosemount. Furthermore,<br />

a HART® hand-held terminal (with DD software) can also be<br />

used. For more information about configuration, please refer<br />

to the separate Operating Instructions for the ES.<br />

Safety class: DMT 00 ATEX 075 / II2G EEx ia IIC T6<br />

When installing electrical equipment in hazardous areas,<br />

the conditions and provisions specified in the approval<br />

docmuments must be followed.<br />

5.3 Analog output with the KINAX 3W2<br />

angle-of-rotation transmitter<br />

The signal output of the angle-of-rotation transmitter is<br />

factory-calibrated to the scale values. The signal output is 4-<br />

20 mA in 2-wire connection; or alternatively 0-20 mA in 4- or<br />

3-wire connection. The signal output of 4 mA corresponds to<br />

the flow rate scale value of 0 (0 mA for the 0-20 mA version).<br />

5.6 mA corresponds to 10% of the flow rate scale value<br />

(2 mA). 20 mA corresponds to 100% of the flow rate scale<br />

value.<br />

Use in hazardous areas:<br />

The angle-of-rotation transmitter is a component approved<br />

for hazardous areas. When used in hazardous areas, all the<br />

values and instructions indicated in the certificate of approval<br />

must be observed. Auxiliary power is fed through an<br />

approved intrinsically safe circuit of 12-30 V. To prove<br />

intrinsic safety, only authorized electrical equipment may be<br />

interconnected. Please take note of the maximum<br />

permissible ambient temperature of 60°C/75°C for the<br />

transmitter and the process temperature.<br />

Safety class:<br />

PTB 97 ATEX 2271 / II 2G EEx ia IIC T6<br />

6 Characteristic values<br />

6.1 Measuring accuracy<br />

6.1.1 Reference conditions<br />

Water 20°C<br />

6.1.2 Measured error<br />

(for liquids)<br />

BGN-S/H/P +/- 1.6% of URV for local display<br />

(URV = upper-range value)<br />

(for gases)<br />

BGN-S/H/P +/- 2.0% of URV for local display<br />

Additional inaccuracy for:<br />

ES = +/- 0.2%<br />

KINAX 3W2 = +/- 0.5%<br />

6.1.3 Repeatability<br />

+/- 0.5 % of upper-range value<br />

6.2 Influence of ambient temperature<br />

1. Without electrical equipment and with limit transducer<br />

without influence<br />

2. With KINAX transmitter:<br />

+/- 0.2 % / 10 K reference temperature 23°C<br />

3. With ES transmitter:<br />

+/- 0.5 % / 10 K reference temperature 22°C<br />

6.3 Influence of fluid temperature<br />

Deviations in fluid temperature from the temperature<br />

observed during calibration can result in a proportional<br />

display fault because of the corresponding change in<br />

density. Changes in viscosity cause a non-linear display<br />

fault.<br />

7 Conditions of use<br />

The VDI/VDE guidelines 3513, Sheet 3, must be observed.<br />

The meter is suitable for :<br />

1) Liquids with sufficient flowability that are free of<br />

solids, do not bond and do not tend to settle.<br />

2) Gases with linear flow behavior and an adequate<br />

inlet pressure.<br />

7.1 Mounting requirements<br />

The mounting location must be suitable for a vertical<br />

direction of flow from the bottom to the top.<br />

Important: If that is impossible, then the device type BGF<br />

may be utilized. This device can be used for both horizontal<br />

and vertical direction of flow.<br />

Page 6 of 28

Heinrichs Messtechnik<br />

The limit values for temperature and air humidity at the<br />

mounting location must be maintained. Avoid corrosive<br />

atmospheres. If this cannot be avoided, ventilation must be<br />

installed.<br />

Please make sure that there is adequate clearance from<br />

parts that might cause magnetic interferences such as<br />

solenoid valves and ferromagnetic components like steel<br />

brackets/supports. We recommend that the minimum lateral<br />

distance between two adjacently mounted devices be<br />

300 mm. The devices can be mounted close together if<br />

vertically offset by one device length. The minimum lateral<br />

clearance for interfering steel parts should be 200 mm. In<br />

case of doubt, check the interference by moving the device<br />

back and forth in the selected distance by about 200 mm<br />

and testing whether the pointer position changes.<br />

Select the mounting location so as to enable a reliable<br />

reading of the scale values. Please take note as well of the<br />

space requirement for any possible disassembly of the<br />

device. As a rule, inlet and outlet sections in front of and<br />

behind the device are unnecessary if the medium has a<br />

linear flow profile. Avoid mounting accessories converging<br />

on one side in front of the device. However, if this is<br />

indispensable maintain a minimum device length of 250 mm<br />

as an inlet section.<br />

The nominal size of the pipes to be connected must<br />

correspond to that of the meter. Avoid fittings converging on<br />

one side directly in front of the device. As a rule, install<br />

valves behind the measuring equipment if there are gases<br />

involved.<br />

7.1.1 Mounting/start-up<br />

The device must be mounted in accordance with the<br />

direction of flow from the bottom to the top (perpendicularly).<br />

Please observe the prior reference to the BGF-type device.<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

If there is risk of dirt or solid matter penetrating the process<br />

pipes, flush them beforehand so that these materials do not<br />

get caught in the device. Ferromagnetic solid matter such<br />

as spatter can lead to the breakdown of the device. If these<br />

materials are still present during normal operating<br />

conditions, mount a magnetic filter (accessory) in front of the<br />

device. When using liquids, flush to avoid a surge of gas<br />

bubbles. Slowly increase the supply pressure when using<br />

gases to prevent pressure surges. Basically, avoid<br />

activation using solenoid valves to prevent the float from<br />

shooting upwards.<br />

7.1.1.1 Gas measurement<br />

When using gases, slowly let the operating pressure rise. At<br />

the same time, vary the operating pressure through a setting<br />

valve so that the float is not knocked around since otherwise<br />

this would damage the measuring element.<br />

7.1.2 <strong>Device</strong> settings<br />

The measuring equipment is delivered ready for operation<br />

according to your order specifications. The limit<br />

transducers are set to the desired values. If you have<br />

submitted no requirements, the basic setting for<br />

1 contact device: - Minimum contact switching point at 10%<br />

of descending flow (damped/closed-circuit principle).<br />

2 contact devices: Minimum contact switching point at 10%<br />

of descending flow and maximum contact switching point at<br />

90% of ascending flow.<br />

7.1.3 Adjusting the limit transducer<br />

The contacts are adjustable through the contact position<br />

indicators located on the scale. Dismantle the indicator<br />

cover, unfasten the contact position indicators, set to the<br />

desired value and reattach them.<br />

The nominal size of the device and that of the pipes must be<br />

the same. The pressure stages and, hence, the dimensions<br />

of the flanges must coincide. The surface roughness of the<br />

flange sealing surface must be suitable for the prescribed<br />

gaskets.<br />

Please check whether possible accessories like spring<br />

stops, gas/liquid-type dampers are still correctly sitting on the<br />

flange. Check whether the mounting clearance between the<br />

flanges of the pipes corresponds to the assembly dimension<br />

of the device plus two gaskets. To achieve stress-free<br />

mounting, the flanges of the pipes must be aligned parallel to<br />

each other.<br />

Use connecting bolts and gaskets in the prescribed<br />

dimensions. The gaskets must be suitable for the operating<br />

pressure, the temperature and the measured medium. With<br />

PTFE-coated devices, use gaskets whose interior and<br />

exterior diameter correspond to the sealing strip of the<br />

device.<br />

Tighten the screws crosswise so that the process<br />

connections are tight. See to the tightening torques of<br />

screws especially with PTFE-coated devices.<br />

The maximum torques for PTFE-coated devices are:<br />

DN15/DN25 = 14 Nm/DN50 = 25 Nm/DN80 = 35 Nm/DN100<br />

= 42 Nm (following VDI/VDE Guideline 3513).<br />

Please check whether the pipe is adequately stable to rule<br />

out the possibility of vibration or swinging of the device. (Do<br />

not use steel mounting parts on the device.)<br />

When gas is used as the medium, pay special attention to<br />

the position of the valve. If the device is calibrated to more<br />

than 1.013 bars absolute pressure, the valve is usually<br />

installed behind the flowmeter. At 1.013 bars absolute<br />

pressure (free exhaust) install it in front of the device.<br />

Page 7 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

7.1.4 Operation in hazardous areas<br />

7.1.4.1 Without electrical equipment<br />

The basic version of the flowmeter is a non-electrical device<br />

without its own ignition sources and meets DIN EN 13463-1<br />

requirements. It can be used in hazardous areas that<br />

require Category 2 equipment.<br />

Example for calculating the max. fluid temperature<br />

based on the max. ambient temperature for the built-in<br />

sensor Type ES for DN 15/25.<br />

T a = 70°C<br />

T amb = 60°C<br />

F = 0.2<br />

Marking:<br />

II 2GD c<br />

Tech. File Ref. 03-02 X<br />

⎛ Ta −Tamb<br />

⎞ ⎛ 70 ° C − 60°<br />

C ⎞<br />

Tm = ⎜ ⎟ + Tamb = ⎜<br />

⎟ + 60°<br />

C = 110°<br />

C<br />

⎝ F ⎠ ⎝ 0,2 ⎠<br />

Since the device does not have its own power sources that<br />

would result in a temperature increase, the fluid temperature<br />

is decisive for the maximum surface temperature.<br />

When used in potentially explosive dust atmospheres, the<br />

device must be cleaned regularly in order to avoid deposits<br />

exceeding 5 mm.<br />

7.1.4.2 With built-in electrical limit transducers<br />

When the limit transducers are installed, the device becomes<br />

an electrical assembly and receives a marking in accordance<br />

with DIN EN 50014 from the entire device with the built-in<br />

electrical limit transducers.<br />

The electrical and thermal data and the special conditions of<br />

the EC Type Examination Certificate of the built-in limit<br />

transducers must be observed (see also the diagram in<br />

Section 7.3.2).<br />

The influence of the fluid temperature on the built-in limit<br />

transducers must be observed. The overtemperature of the<br />

maximum fluid temperature based on the maximum ambient<br />

temperature must be considered with a factor according to<br />

the following table:<br />

Nominal size<br />

Factor for<br />

standard<br />

version<br />

DN15 and DN25 0.2 0.07<br />

DN40 and DN50 0.25 0.085<br />

DN80 and DN100 0.3 0.1<br />

Example for built-in limit transducer for<br />

DN 15 and DN 25:<br />

Max. ambient temperature T amb = 40°C<br />

Max. fluid temperature T m = 120°C<br />

Factor for brought-in heat F = 0.2<br />

Temperature class T4<br />

T ü =<br />

T a =<br />

Overtemperature<br />

Ambient temperature of<br />

limit transducer<br />

Tü = Tm −Tamb<br />

= 120 ° C − 40°<br />

C = 80°<br />

C<br />

Ta = Tü * F + Tamb = 80°<br />

C *0,2 + 40°<br />

C = 56°<br />

C<br />

Factor for the<br />

device with the<br />

indicator pulled<br />

forward<br />

In accordance with the tables in the<br />

PTB 99 ATEX 2219 X EC Type Examination Certificate, the<br />

SJ 3,5-... N... inductive sensor must be operated in the<br />

T5 temperature class with an intrinsically safe circuit that<br />

does not exceed the maximum values of the Type 3 circuit.<br />

When using the device in hazardous areas, follow the<br />

applicable national installation rules.<br />

7.1.4.2.1 Marking for the device when the<br />

SJ 3,5...N... limit transducer is built in<br />

PTB 99 ATEX 2219 X<br />

II 2G EEx ia IIC T6-T4<br />

7.1.4.2.2 Marking for the device when the ES magnetoelectric<br />

transmitter is built in<br />

DMT 00 ATEX 075<br />

II2G EEx ia IIC T6<br />

7.1.4.2.3 Marking for the device when the KINAX 3W2<br />

angle-of-rotation transmitter is built in<br />

PTB 97 ATEX 2271<br />

II 2G EEx ia IIC T6<br />

7.2 Ambient conditions<br />

7.2.1 Ambient temperature ranges<br />

Without electrical accessories:<br />

-40°C to +80°C<br />

With limit transducer:<br />

-40 °C to +65°C<br />

With KINAX signal output:<br />

-40°C to +60°C<br />

With ES signal output:<br />

-40°C to +70°C<br />

For the hazardous area version, take note of the maximum<br />

ambient temperatures depending on the temperature class<br />

as specified in the Type Examination Certificate.<br />

7.2.2 Storage temperature<br />

The storage temperatures are identical to the ambient<br />

temperature ranges.<br />

7.2.3 Climatic category<br />

Weather-protected and/or unheated locations, class C<br />

7.2.4 Degree of protection<br />

IP 65<br />

7.2.5 Shock resistance/vibration resistance<br />

The meter should be protected from extreme shocks and<br />

vibrations, which could cause damage.<br />

7.2.6 Electromagnetic compatibility<br />

EN 61000-6-2:1999 Immunity industrial environment<br />

EN 50081-1 Emitted interference residential environment<br />

EN 55011:1998+A1:1999 Group 1, Class B<br />

NAMUR recommendation NE 21<br />

Page 8 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

7.3 Fluid conditions<br />

7.3.1 Fluid temperature ranges<br />

BGN-S/H : - 40°C to +200°C<br />

Special design: -80°C to +350°C<br />

BGN-P : - 20°C to +125°C<br />

7.3.2 Diagrams: Max. ambient temperature based on the fluid temperature for the ES<br />

Standard version<br />

70,0<br />

Max. ambient temperature [°C]<br />

60,0<br />

50,0<br />

40,0<br />

30,0<br />

20,0<br />

70 80 90 100 110 120 130 140 150 160 170 180 190 200<br />

Fluid temperature [°C]<br />

DN15/25 DN40/50 DN80/100<br />

Indicator pulled forward<br />

70,0<br />

Max. ambient temperature [°C]<br />

65,0<br />

60,0<br />

55,0<br />

70 80 90 100 110 120 130 140 150 160 170 180 190 200<br />

Fluid temperature [°C]<br />

DN15/25 DN40/50 DN80/100<br />

Page 9 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

7.3.3 Fluid pressure limit<br />

Standard design BGN-S/H – DN 15/25/40/50/80 PN 40;<br />

DN 100 PN 16<br />

Special design – up to PN 400<br />

BGN-P – DN 15/25/50/80/100 PN 16<br />

7.3.4 Inlet and outlet sections<br />

Inlet and outlet sections are not required for a linear flow<br />

profile of the fluid. For an extremely non-linear flow profile<br />

(e.g. shut-off/control valves are located in front of the meter),<br />

we recommend an inlet section with a mounting length of<br />

250 mm (see also guidelines in accordance with<br />

VDI/VDE 3513).<br />

7.3.5 Physical state<br />

Liquid or gaseous<br />

7.3.6 Density<br />

Liquids: up to 2.0 kg/l<br />

Gases: no restrictions<br />

7.3.7 Viscosity<br />

The influence of viscosity depends on various factors.<br />

Therefore, it must be calculated for each application.<br />

7.3.8 Pressure (for gas measurement)<br />

The measured values only apply to the calibrated fluid data<br />

stated on the scale. Any change or deviation in pressure will<br />

cause a display fault.<br />

7.3.9 Pressure loss<br />

Depends on the meter size and the measuring range (see<br />

Measuring range table).<br />

Page 10 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

8 Construction details<br />

8.1 Type of construction/dimensions<br />

8.1.1 Aluminum indicator housing<br />

8.1.2 Dimension drawing for heating<br />

connection<br />

Deviating mounting dimensions:<br />

(1) With preceding magnetic filter, 50 mm longer<br />

plus 2 gaskets<br />

(2) 265 mm with the indicator pulled forward<br />

(3) 175 mm with the indicator pulled forward<br />

(4) For special design DN 100: 120 mm<br />

8.1.2.1 Connections for heating jacket<br />

Pipe for<br />

Ermeto 12 mm<br />

Flange in acc. with DIN DN 15 or DN 25 PN 40<br />

Flange in acc. with ANSI ½“ 150 lbs<br />

The DN 25 flange is a special version.<br />

Dimensions:<br />

DN PN Inside diameter A<br />

15 40 26 74<br />

25 40 32 77<br />

40 40 46 88<br />

50 40 70 97<br />

80 16 102 113<br />

Page 11 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

8.1.3 Indicator housing made of stainless<br />

steel<br />

8.2 Weight<br />

Nominal size Weight [kg]<br />

DN 15 3<br />

DN 25 4.2<br />

DN 40 6<br />

DN 50 7.5<br />

DN 80 13<br />

DN 100 18<br />

Nominal size<br />

¾“, 150 lbs, ANSI<br />

B16.5<br />

1“, 150 lbs, ANSI<br />

B16.5<br />

1 ½“, 150 lbs, ANSI<br />

B16.5<br />

2“, 150 lbs, ANSI<br />

B16.5<br />

3“, 150 lbs, ANSI<br />

B16.5<br />

4“, 150 lbs, ANSI<br />

B16.5<br />

Weight [kg]<br />

3<br />

4.2<br />

6<br />

7.5<br />

13<br />

18<br />

Nominal size<br />

¾“, 300 lbs, ANSI<br />

B16.5<br />

1“, 300 lbs, ANSI<br />

B16.5<br />

1 ½“, 300 lbs, ANSI<br />

B16.5<br />

2“, 300 lbs, ANSI<br />

B16.5<br />

3“, 300 lbs, ANSI<br />

B16.5<br />

4“, 300 lbs, ANSI<br />

B16.5<br />

Weight [kg]<br />

3.4<br />

4.7<br />

6.8<br />

8.5<br />

14.5<br />

20<br />

DN PN Inside diameter A<br />

15 40 26 100<br />

25 40 32 103<br />

40 40 46 110<br />

50 40 70 122<br />

80 16 102 138<br />

Deviating mounting dimensions:<br />

(1) 265 mm with the indicator pulled forward<br />

Page 12 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

8.3 Material<br />

Fitting<br />

Type<br />

Measuring tube Lining of<br />

measuring<br />

tube<br />

Flanges Flange lining Float<br />

BGN – S Stainless steel none Stainless steel none Stainless steel<br />

BGN – P Stainless steel PTFE Stainless steel PTFE PTFE<br />

BGN – H DN15/25 ¾“/1“ Hastelloy HC4 none Hastelloy HC4 none Hastelloy HC4<br />

BGN – H > DN40 / 1½” Hastelloy HC4 none Stainless steel Hastelloy HC4 Hastelloy HC4<br />

Indicator<br />

Type Base plate Housing<br />

BGN – S/P/H Aluminum Aluminum, safety glass window<br />

Optional Stainless steel Stainless steel, safety glass window<br />

8.4 Process connection<br />

BGN-S/H<br />

BGN-P<br />

DN 15 PN 40 PN 16<br />

DN 25 PN 40 PN 16<br />

DN 40 PN 40 PN 16<br />

DN 50 PN 40 PN 16<br />

DN 80 PN 40 PN 16<br />

DN 100 PN 16 PN 16<br />

BGN S/ H<br />

BGN P<br />

ANSI ¾“ B16.5 150 lbs 1) 300 lbs 1) 150 lbs 2) 300 lbs 2)<br />

ANSI 1“ B16.5 150 lbs 1) 300 lbs 1) 150 lbs 2) 300 lbs 2)<br />

ANSI 1 ½“ B16.5 150 lbs 1) 300 lbs 1) 150 lbs 2) 300 lbs 2)<br />

ANSI 2“ B16.5 150 lbs 1) 300 lbs 1) 150 lbs 2) 300 lbs 2)<br />

ANSI 3“ B16.5 150 lbs 1) 300 lbs 1) 150 lbs 2) 300 lbs 2)<br />

ANSI 4“ B16.5 150 lbs 2) 300 lbs 2) 150 lbs 2) 300 lbs 2)<br />

1) Entire device PN 40 2) Entire device PN 16<br />

Additional equipment: special flanges, union, food connection, welding connection<br />

The S/H versions in special design are available up to PN 400.<br />

8.5 Magnetic filter<br />

The BGN flowmeter is sensitive to impure media. Before<br />

installing the device, clean the pipes of dirt, spatter and other<br />

foreign matter. If the medium comes with solid particles,<br />

connect a suitable filter in series. When dealing with flow<br />

media with ferrous particles, we recommend the connection<br />

of a magnetic filter.<br />

To protect both magnetic filter types, MF-S (stainless steel)<br />

and MF-P/S (PTFE/stainless steel), from corrosion,<br />

encapsulated permanent magnets are laid out in spiral form.<br />

The spiral mounting produces optimum effect at small<br />

pressure loss. The filter can be supplied with groove or<br />

tongue, projection or return, other standards or special<br />

connections according to customer wishes.<br />

Dimensions:<br />

DN<br />

g (mm)<br />

15 45<br />

25 68<br />

40 88<br />

50 102<br />

65 122<br />

80 138<br />

100 158<br />

Page 13 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

8.6 Electrical connection<br />

Wiring<br />

To connect the auxiliary power, remove the indicator cover, insert the connector cable into the cable gland and attach it to the<br />

terminals according to terminal diagram. Tighten the cable gland securely, remount the indicator cover and close it tightly.<br />

8.6.1 Wiring diagram for ES transmitter (signal output 4-20 mA with HART®)<br />

8.6.2 Wiring diagram for ES transmitter with 4-20 mA output and 2 limit transducers<br />

Page 14 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

8.6.3 Wiring diagram for ES transmitter with 4- 20 mA output, pulse output and limit transducer<br />

8.6.4 Wiring diagram for inductive limit transducers<br />

Page 15 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

8.6.5 Wiring diagram for KINAX 3W2 transmitter with 4-20 mA output, 2 wires<br />

8.6.6 Wiring diagram for KINAX 3W2 transmitter with 4-20 mA output, 3 wires<br />

Page 16 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

8.6.7 Wiring diagram for KINAX 3W2 transmitter with 4-20 mA output, 4 wires<br />

8.6.8 Wiring diagram for KEM 1 and KEM 2 double-throw microswitches<br />

Page 17 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

9 Indicator unit<br />

- Analog indicator approx. 90° with pointer<br />

- Customized product scale<br />

- ES transmitter with freely programmable user interface<br />

- Parameters may be changed based on the ES<br />

Operating Instructions.<br />

10 Auxiliary power<br />

see Electrical connection<br />

11 CE mark<br />

The measuring system meets the statutory requirements of<br />

the following EU directives: Directive 94/9/EC (Equipment<br />

and Protective Systems for Use in Potentially Explosive<br />

Atmospheres), the Electromagnetic Compatibility (EMC)<br />

Directive 89/336/EEC and the Pressure Equipment Directive<br />

97/23/EC.<br />

Measuring sensors with a connection nominal size equal to<br />

or smaller than or DN 25 fall within the scope of application<br />

of Article 3, section 3, of the Pressure Equipment Directive<br />

and need no CE mark in accordance with this directive.<br />

Heinrichs Messtechnik confirms compliance with the<br />

directives by attaching the CE mark.<br />

12 Order information<br />

Please include the following information in your order:<br />

Product data, specific weight, temperature, pressure,<br />

viscosity, material design, connection size, measuring range,<br />

desired accessories, required approvals and material<br />

certificates. See <strong>Device</strong> selection by model code.<br />

12.1 Available accessories<br />

- Stainless steel indicator unit, glass window IP 66<br />

- Indicator unit for high or low temperatures pulled<br />

forward by 100 mm<br />

- Fitting with heating or cooling jacket (with Ermeto or<br />

flange connection)<br />

- Float system with viscous damping<br />

- Float system with gas damping<br />

- Float system with spring stop<br />

- 1 or 2 inductive limit transducers<br />

- KINAX or ES electric transmitter<br />

- Drainable fitting (pump has been disconnected)<br />

- Magnetic filter<br />

13 Standards and directives,<br />

certificates and approvals<br />

- Certified to DIN-EN 9001<br />

- Production in accordance with AD guidelines and HPO<br />

approval (TRB200/TRD201)<br />

- TÜV approval for welding requirements in accordance<br />

with DIN-EN 729-2<br />

- Measuring range rated and converted to other products<br />

according to VDE/VDI guidelines 3513<br />

- Directive 94/9/Ec (Equipment and Protective Systems<br />

for Use in Potentially Explosive Atmospheres)<br />

- EN 50014:1997+A1-A2 - General requirements<br />

- EN 50020:1994 - Intrinsic safety “i”<br />

- Directive 89/336/EEC (EMC Directive)<br />

- EN 61000-6-2:1999 – Immunity industrial environment<br />

- EN 50 081-1 – Emitted interference residential<br />

environment<br />

- EN 55011:1998+A1:1999 – Group 1, Class B<br />

- NAMUR recommendation NE 21<br />

- EN 60529 – Degrees of protection through housing (IP<br />

code)<br />

- EN 61010 – Safety requirements for electrical<br />

measuring, control and laboratory devices<br />

- EN 60947-5-6:2000 – Switchgear and controlgear<br />

- Directive 97/23/EC (Pressure Equipment Directive)<br />

14 Replacement parts<br />

The following parts can be ordered as replacement parts:<br />

1 ) Indicator cover with<br />

window/gasket/screws<br />

2 ) Scale with standard scaling<br />

3 ) Pointer<br />

4 ) Limit value indicator<br />

5 ) Pointer stop<br />

6 ) Float with guides and safety screw<br />

7 ) Spring stop<br />

8 ) Complete gas damping set with float<br />

9 ) Complete viscous damping set with float<br />

10) Screwed cone set with float for<br />

small measuring range up to 40 l/h<br />

11 ) Limit value initiatior<br />

Page 18 of 28

Heinrichs Messtechnik<br />

15 Exploded views<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

15.1.2 BGN-.... with spring stop<br />

15.1 Fitting with measuring element<br />

Name<br />

(Figures 12-16)<br />

Part no.<br />

Fitting 1<br />

Float 2<br />

Spring stop for float 3 / 4<br />

Cone with float, gasket and stop<br />

(Fig. 16)<br />

2/3/4<br />

Complete BGN gas damping set<br />

with float (Fig. 14)<br />

2/3/4<br />

4<br />

3<br />

2<br />

15.1.1 BGN-.... Standard version<br />

1<br />

2<br />

Figure 13<br />

15.1.3 BGN-.... with damping piston<br />

1<br />

4<br />

3<br />

Figure 12<br />

2<br />

1<br />

Figure 14<br />

Page 19 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

15.1.4 BGN-.... with damping piston and<br />

spring stop<br />

4<br />

3<br />

2<br />

1<br />

Figure 15<br />

15.1.5 BGN-.... small measuring ranges<br />

1<br />

2<br />

3<br />

4<br />

Figure 16<br />

Page 20 of 28

Heinrichs Messtechnik<br />

15.2 Indicator unit<br />

Name<br />

Part<br />

no.<br />

Mounting plate with 1 thread M 20 x 1.5 10<br />

Mounting plate with 2 threads M 20 x 1.5 11<br />

Bearing unit 20<br />

Fixing screws for bearing unit 30<br />

Dummy plug M 20 x 1.5 40<br />

Cable gland 41<br />

Cable gland 42<br />

Scale, blank 50<br />

Scale, product scale according to original shipment (order no.<br />

necessary)<br />

51<br />

Screw for fixing the scale 60<br />

Zero-point screw with nut 70<br />

Indicator cover with glass window, gasket, screws 80<br />

Scale pointer with hub 90<br />

Scale pointer with hub and 2 switching dials 91<br />

Scale pointer with hub and linearization disc 92<br />

Scale pointer with hub and linearization disc/switching dial 93<br />

Scale pointer with hub and 2 switching dials and ES position<br />

magnet<br />

94<br />

1. SJ 3,5 N limit transducer with limit value indicator 110<br />

1. SJ 3,5 SN limit transducer with limit value indicator 111<br />

2. SJ 3,5 N limit transducer with limit value indicator 120<br />

2. SJ 3,5 SN limit transducer with limit value indicator 121<br />

Connection plate for 1 limit transducer with mounting parts 130<br />

Connection plate for 2 limit transducers with mounting parts 131<br />

Installation set for transmitter type KINAX 3W2 Ex with<br />

lever arm and mounting parts<br />

132<br />

Installation set transmitter type KINAX 3W2 Ex with<br />

lever arm and mounting parts and connection for a limit 133<br />

transducer<br />

Installation set transmitter ES Ex Hart 140<br />

Installation set transmitter ES Ex with switch (min-max) 141<br />

Installation set transmitter ES Ex with Profibus 142<br />

15.2.1 Complete indicator unit, local with<br />

scale<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

15.2.2 Complete indicator unit with 1 SJ 3,5<br />

N limit transducer<br />

70<br />

60<br />

30<br />

Figure 2<br />

15.2.3 Complete indicator unit with 2 SJ 3,5<br />

N limit transducers<br />

80<br />

50<br />

70<br />

110<br />

111<br />

91<br />

130<br />

20<br />

30<br />

41<br />

10<br />

80<br />

80<br />

50<br />

70<br />

70<br />

70<br />

60<br />

50<br />

70<br />

60<br />

120<br />

121<br />

110<br />

111<br />

90<br />

91<br />

20<br />

131<br />

30<br />

30<br />

20<br />

30<br />

30<br />

40<br />

Figure 1<br />

Figure 3<br />

41<br />

10<br />

10<br />

Page 21 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

15.2.4 Complete indicator unit with E2<br />

KINAX Ex transmitter<br />

15.2.6 Indicator unit with transmitter type<br />

ES Ex HART®<br />

80<br />

80<br />

50<br />

50<br />

70<br />

70<br />

70<br />

70<br />

60<br />

60<br />

(141)<br />

(142)<br />

140<br />

94<br />

92<br />

20<br />

132<br />

30<br />

30<br />

30<br />

20<br />

30<br />

42<br />

Figure 4<br />

41<br />

Figure 6<br />

10<br />

10<br />

15.2.5 Complete indicator unit with E2<br />

KINAX Ex transmitter and 1 SJ 3,5 N limit<br />

transducer<br />

70<br />

60<br />

110<br />

111<br />

30<br />

Figure 5<br />

80<br />

50<br />

70<br />

93<br />

133<br />

20<br />

30<br />

41<br />

11<br />

Name<br />

Part<br />

no.<br />

Mounting plate with 1 thread M 20 x 1.5 10<br />

Mounting plate with 2 threads M 20 x 1.5 11<br />

Bearing unit 20<br />

Fixing screws for bearing unit 30<br />

Dummy plug M 20 x 1.5 40<br />

Cable gland 41<br />

Cable gland 42<br />

Scale, blank 50<br />

Scale, product scale according to original shipment (order<br />

no. necessary)<br />

51<br />

Screw for fixing the scale 60<br />

Zero-point screw with nut 70<br />

Indicator cover with glass window, gasket, screws 80<br />

Scale pointer with hub 90<br />

Scale pointer with hub and 2 switching dials 91<br />

Scale pointer with hub and linearization disc 92<br />

Scale pointer with hub and linearization disc/switching<br />

dial<br />

93<br />

Scale pointer with hub and 2 switching dials and ES<br />

position magnet<br />

94<br />

1. SJ 3,5 N limit transducer with limit value indicator 110<br />

1. SJ 3,5 SN limit transducer with limit value indicator 111<br />

2. SJ 3,5 N limit transducer with limit value indicator 120<br />

2. SJ 3,5 SN limit transducer with limit value indicator 121<br />

Connection plate for 1 limit transducer with mounting<br />

parts<br />

130<br />

Connection plate for 2 limit transducers with mounting<br />

parts<br />

131<br />

Installation set for transmitter type KINAX 3W2 Ex with<br />

lever arm and mounting parts<br />

132<br />

Installation set transmitter type KINAX 3W2 Ex with lever<br />

arm and mounting parts and connection for a limit 133<br />

transducer<br />

Installation set transmitter ES Ex Hart 140<br />

Installation set transmitter ES Ex with switch (min-max) 141<br />

Installation set transmitter ES Ex with Profibus 142<br />

Page 22 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

16 EC Type Examination Certificate<br />

Page 23 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

Page 24 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

Page 25 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

Page 26 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

Page 27 of 28

Heinrichs Messtechnik<br />

<strong>Device</strong> <strong>Description</strong> <strong>Variable</strong> <strong>Area</strong> <strong>Flowmeter</strong> BGN<br />

17 Sales representatives<br />

ADINCO BV, Bosmanskamp 30, 4191 MV Geldermalsen.<br />

tel +31 345 596 000, fax +31 345 596 001, heinrichs@adinco.nl<br />

18 Notes www.heinrichs-mt.nl<br />

Page 28 of 28

Since 1970<br />

Representative for<br />

Heinrichs<br />

www.heinrichs-mt.nl<br />

<strong>Adinco</strong> <strong>bv</strong><br />

P.O.Box 90<br />

4190 CB Geldermalsen<br />

Netherlands<br />

Tel. +31 (0) 345 59 60 00<br />

Fax +31 (0) 345 59 60 01<br />

E-mail: info@adinco.nl<br />

Internet: www.adinco.nl