PDF file - Facultatea de Chimie şi Inginerie Chimică

PDF file - Facultatea de Chimie şi Inginerie Chimică

PDF file - Facultatea de Chimie şi Inginerie Chimică

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

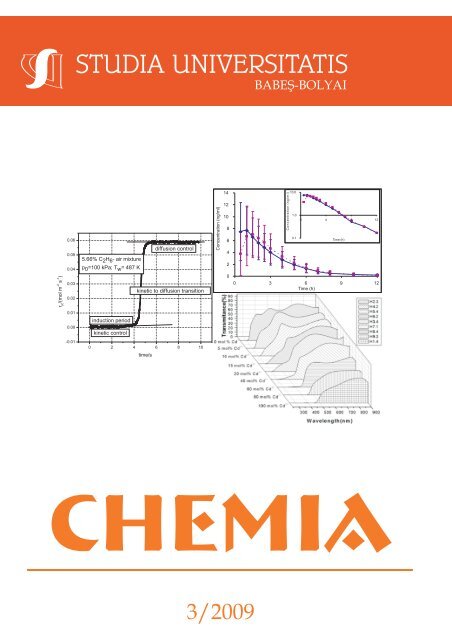

R /(mol m -2 s -1 )<br />

0.06<br />

0.05<br />

0.04<br />

0.03<br />

0.02<br />

0.01<br />

0.00<br />

-0.01<br />

5.66% C2H6-airmixture p0 =100 kPa; Tw =487K<br />

induction period<br />

kinetic control<br />

kinetic to diffusion transition<br />

0 2 4 6 8 10<br />

time/s<br />

diffusion control<br />

Concentration (ng/ml)<br />

CHEMIA<br />

14<br />

12<br />

10<br />

3/2009<br />

8<br />

6<br />

4<br />

2<br />

0<br />

Concentration (ng/ml)<br />

10.0<br />

1.0<br />

0 4 8 12<br />

0.1<br />

Time (h)<br />

0 3 6 9 12<br />

Time (h)

ANUL LIV 2009<br />

S T U D I A<br />

UNIVERSITATIS BABEŞ-BOLYAI<br />

CHEMIA<br />

3<br />

Desktop Editing Office: 51 ST B.P. Has<strong>de</strong>u Street, Cluj-Napoca, Romania, Phone + 40 264-405352<br />

CUPRINS – CONTENT – SOMMAIRE – INHALT<br />

LIANA MUREŞAN, ALEXANDRA CSAVDÁRI, Professor Ioan Bâl<strong>de</strong>a<br />

at his 70’s Anniversary ..............................................................................5<br />

MARCELA ACHIM, DANA MUNTEAN, LAURIAN VLASE, IOAN BÂLDEA,<br />

DAN MIHU, SORIN E. LEUCUŢA, New LC/MS/MS Method for the<br />

Quantification of Phenytoin in Human Plasma ...................................... 7<br />

ECATERINA BICA, LAURA ELENA MUREŞAN, LUCIAN BARBU-<br />

TUDORAN, EMIL INDREA, IONEL CĂTĂLIN POPESCU,<br />

ELISABETH-JEANNE POPOVICI, Studies on WO3 Thin Films<br />

Prepared by Dip-Coating Method ........................................................ 15<br />

ADRIAN-IONUŢ CADIŞ, ADRIAN RAUL TOMŞA, ECATERINA BICA,<br />

LUCIAN BARBU-TUDORAN, LUMINIŢA SILAGHI-DUMITRESCU,<br />

ELISABETH-JEANNE POPOVICI, Preparation and Characterization<br />

of Manganese Doped Zinc Sulphi<strong>de</strong> Nanocrystalline Pow<strong>de</strong>rs<br />

With Luminescent Properties............................................................... 23<br />

COSMIN CĂŢĂNAŞ, MIHAI MOGOŞ, DANIEL HORVAT, JAKAB<br />

ENDRE, ELEONORA MARIA RUS, IULIU OVIDIU MARIAN,<br />

Electrical Characteristics of a Biobattery with Staphylococcus Aureus ..... 31

ANA-MARIA CORMOS, JOZSEF GASPAR, ANAMARIA PADUREAN,<br />

Mo<strong>de</strong>ling and Simulation of Carbon Dioxi<strong>de</strong> Absorption in<br />

Monoethanolamine in Packed Absorption Columns............................ 37<br />

EUGEN DARVASI, LADISLAU KÉKEDY-NAGY, Red Pepper Pow<strong>de</strong>r<br />

Color Measurement by Using an Integrating Sphere and Digital<br />

Image Processing................................................................................ 49<br />

VALENTINA R. DEJEU, BARABÁS RÉKA, POP ALEXANDRU,<br />

BOGYA ERZSÉBET SÁRA, PAUL-ŞERBAN AGACHI, Mathematical<br />

Mo<strong>de</strong>ling for the Crystallization Process of Hydroxyapatite<br />

Obtained by Precipitation in Aqueous Solution ................................... 61<br />

SILVIA LENUŢA DUNCA, MONICA KULCSAR, ANCA SILVESTRU,<br />

CRISTIAN SILVESTRU, COSTEL SÂRBU, Study of The<br />

Chromatographic Retention of Some New Organoselenium and<br />

Organotellurium Compounds Containing Intramolecular Interactions<br />

by HPTLC............................................................................................ 71<br />

NATHAN FLEURET, SEBASTIAN PAIC, GABRIELA NEMES,<br />

RALUCA SEPTELEAN, PETRONELA PETRAR, IOAN SILAGHI-<br />

DUMITRESCU, Lower Rim Silyl Substituted Calix[8]Arenes .............. 81<br />

OSSI HOROVITZ, MARIA TOMOAIA-COTIŞEL, CSABA RACZ,<br />

GHEORGHE TOMOAIA, LIVIU-DOREL BOBOŞ, AURORA<br />

MOCANU, The Interaction of Silver Nanoparticles with Lipoic Acid ....... 89<br />

FLORICA IMRE-LUCACI, SORIN-AUREL DORNEANU, PETRU ILEA,<br />

Optimisation of Copper Removal from Diluted Solutions .................... 97<br />

MELINDA-HAYDEE KOVACS, DUMITRU RISTOIU, SIDONIA VANCEA,<br />

LUMINITA SILAGHI-DUMITRESCU, Volatile Organic Disinfection<br />

by Products Determination in Distribution System from Cluj Napoca ... 107<br />

ANDRADA MĂICĂNEANU, COSMIN COTEŢ, VIRGINIA DANCIU,<br />

MARIA STANCA, Iron Doped Carbon Aerogel as Catalyst for<br />

Phenol Total Oxidation ...................................................................... 117<br />

ANDRADA MĂICĂNEANU, HOREA BEDELEAN, SILVIA BURCĂ , MARIA<br />

STANCA, Heavy Metal Ions Removal from Mo<strong>de</strong>l Wastewaters<br />

Using Oraşul Nou (Transilvania, Romania) Bentonite Sample.......... 127<br />

CRISTINA MIHALI, GABRIELA OPREA, ELENA CICAL, PVC Matrx<br />

Ionic - Surfactant Selective Electro<strong>de</strong>s Based on the Ionic Pair<br />

Tetra Alkyl-Ammonium –Laurylsulphate............................................ 141<br />

DAN MIHU, LAURIAN VLASE, SILVIA IMRE, CARMEN M. MIHU,<br />

MARCELA ACHIM, DANIELA LUCIA MUNTEAN, New LC/MS<br />

Method for Determination of Progesterone in Human Plasma for<br />

Therapeutic Drug Monitoring in Pregnancy and Gynecological<br />

Disor<strong>de</strong>rs ........................................................................................... 151

ANCA PETER, MONICA BAIA, FELICIA TODERAS, MIHAELA LAZAR,<br />

LUCIAN BARBU TUDORAN, VIRGINIA DANCIU, Photo-Catalysts<br />

Based on Gold - Titania Composites................................................. 161<br />

TÍMEA PERNYESZI, KRISZTINA HONFI, BORBALA BOROS, KATALIN<br />

TÁLOS, FERENC KILÁR, CORNELIA MAJDIK, Biosorption of Phenol<br />

from Aqueous Solutions by Fungal Biomass of Phanerochaete<br />

Chrysosporium .................................................................................. 173<br />

ANDREI ROTARU, MIHAI GOŞA, EUGEN SEGAL, Isoconversional<br />

Linear Integral Kinetics of the Non-Isothermal Evaporation of<br />

4-[(4-Chlorobenzyl)Oxy]-4’-Trifluoromethyl-Azobenzene .................. 185<br />

OCTAVIAN STAICU, VALENTIN MUNTEANU, DUMITRU OANCEA,<br />

Overall Kinetics for the Catalytic Ignition of Ethane-Air Mixtures<br />

on Platinum........................................................................................ 193<br />

MARIA ŞTEFAN, IOAN BÂLDEA, RODICA GRECU , EMIL INDREA,<br />

ELISABETH-JEANNE POPOVICI, Growth and Characterisation of<br />

Zinc-Cadmium Sulphi<strong>de</strong> Thin Films with Special Optical Properties .... 203<br />

MIHAELA-CLAUDIA TERTIŞ, FLORINA IONESCU, MARIA JITARU,<br />

Equilibrium Study on Adsorption Processes of 4-Nitrophenol and<br />

2, 6-Dinitrophenol Onto Granular Activated Carbon.......................... 213<br />

CAMELIA VARGA, MONICA MARIAN, ANCA PETER, DELIA BOLTEA,<br />

LEONARD MIHALY-COZMUTA, EUGEN NOUR, Strategies of<br />

Heavy Metal Uptake by Phaseolus Vulgaris Seeds Growing in<br />

Metalliferous and Non-Metalliferous Areas........................................ 223<br />

SIMONA VARVARA, MARIA POPA, LIANA MARIA MURESAN,<br />

Corrosion Inhibition of Bronze by Amino Acids in Aqueous Acidic<br />

Solutions............................................................................................ 235<br />

LIDIA VARVARI, SORIN-AUREL DORNEANU, IONEL CĂTĂLIN<br />

POPESCU, Potassium-Selective Electro<strong>de</strong> Based on a CALIX[6]<br />

Arenic Ester (C6ES6) ........................................................................ 247<br />

CODRUTA VARODI, DELIA GLIGOR, LEVENTE ABODI, LIANA<br />

MARIA MURESAN, Comparative Study of Carbon Paste<br />

Electro<strong>de</strong>s Modified with Methylene Blue and Methylene Green<br />

Adsorbed on Zeolite as Amperometric Sensors for H2O2 Detection ..... 255<br />

LAURIAN VLASE, DANA MUNTEAN, ADINA POPA, MARIA NEAG,<br />

IOAN BÂLDEA, MARCELA ACHIM, SORIN E. LEUCUŢA,<br />

Pharmacokinetic Interaction between Ivabradine and Ciprofloxacine<br />

in Healthy Volunteers ........................................................................ 265

Studia Universitatis Babes-Bolyai Chemia has been selected for coverage<br />

in Thomson Reuters products and custom information services. Beginning<br />

with V. 53 (1) 2008, this publication is in<strong>de</strong>xed and abstracted in the following:<br />

• Science Citation In<strong>de</strong>x Expan<strong>de</strong>d (also known as SciSearch®)<br />

• Chemistry Citation In<strong>de</strong>x®<br />

• Journal Citation Reports/Science Edition

Professor Ioan Bâl<strong>de</strong>a at his 70’s Anniversary<br />

Brilliant teacher and warm colleague,<br />

Professor Ioan Bâl<strong>de</strong>a was born on the 21 st<br />

of October 1939. Still active, he <strong>de</strong>dicates<br />

himself to science and teaching after<br />

graduating Babeş-Bolyai University as a<br />

chemist in 1962. Well-known in the aca<strong>de</strong>mic<br />

community as one of the top kineticists<br />

of the country, his 70’s anniversary<br />

finds him with unaltered optimism and<br />

creativeness.<br />

Beginning immediately after graduation<br />

as a teaching assistant, his aca<strong>de</strong>mic<br />

carrier unfol<strong>de</strong>d rigorously step by step, while<br />

obtaining his PhD in 1969. As an appointed<br />

lecturer (1971), associated professor (1990)<br />

and full professor (1993), his work continuously<br />

contributed to the <strong>de</strong>velopment and growth of the Department of Physical<br />

Chemistry.<br />

Besi<strong>de</strong>s over 120 various scientific papers, Professor Ioan Bâl<strong>de</strong>a also<br />

published 4 books as a single author and contributed to 2 others. These<br />

summarize his prodigious experience in chemical kinetics of homogeneous<br />

redox and organic reactions, characterization of short-life chemical complexes,<br />

mo<strong>de</strong>ling of complex processes, <strong>de</strong>sign and reactor engineering as well as<br />

kinetic methods of analysis. This valuable and diverse knowledge was shared<br />

with the young scientists he tutored during their PhD scholarships. It also<br />

contributed both to solving of over 50 contracts and putting forward of 4 patents<br />

for the Romanian chemical industry. A production line for ethyl acetate was<br />

based on his <strong>de</strong>signs and functioned till the early 90’s at the plant in<br />

Craiova. The 12 research Grants he coordinated (among these, one financed<br />

by the World Bank) substantially contributed to the <strong>de</strong>velopment of Chemical<br />

Kinetics and General Physical Chemistry at the Babeş-Bolyai University.<br />

While always en<strong>de</strong>avoring on sharing and passing over his knowledge<br />

to the young generations, Professor Bâl<strong>de</strong>a wrote or collaborated to the<br />

publication of 8 manuals of Physical as well as General Chemistry. The stu<strong>de</strong>nts<br />

highly appreciated the funny and nonconformist explanations; the examples<br />

illustrating daily life ma<strong>de</strong> his lectures colorful and easy to un<strong>de</strong>rstand. The<br />

approximately 100 graduate and postgraduate thesis coordinated by the<br />

Professor stand proof for this fact.

6<br />

PROFESSOR IOAN BÂLDEA AT HIS 70’S ANNIVERSARY<br />

Also beloved and highly regar<strong>de</strong>d by his colleagues, Professor Ioan<br />

Bâl<strong>de</strong>a was elected for nearly 10 years as Head of the Department of Physical<br />

Chemistry and represented for 23 years the same Department in the Faculty’s<br />

Council. He was also the local coordinator of the CEEPUS aca<strong>de</strong>mic exchange<br />

Program for 8 years. The vast experience allowed the Professor to manage the<br />

Program of didactic personnel improvement for 8 years and to be a referee<br />

for various scientific publications, grants and events.<br />

This issue of Studia Universitas Babeş-Bolyai, Seria Chemia reflects<br />

the tight professional relationships Professor Ioan Bâl<strong>de</strong>a has build within<br />

the aca<strong>de</strong>mic community of Romania. Teachers and researchers from the<br />

University of Bucharest, Baia-Mare or Iuliu HaŃieganu University of Medicine<br />

from Cluj-Napoca also contributed to this volume.<br />

Now, at his 70’s anniversary, we – the colleagues of the Department<br />

of Physical Chemistry – as well as all the colleagues and researchers of the<br />

Faculty of Chemistry of the Babeş-Bolyai University, along with the Editorial<br />

Board, wish Professor Ioan Bâl<strong>de</strong>a health in the many years to come, as well<br />

as the spice of current valuable scientific activity.<br />

Volum Editors<br />

Liana Mureşan<br />

Alexandra Csavdári

STUDIA UNIVERSITATIS BABEŞ-BOLYAI, CHEMIA, LIV, 3, 2009<br />

NEW LC/MS/MS METHOD FOR THE QUANTIFICATION<br />

OF PHENYTOIN IN HUMAN PLASMA<br />

MARCELA ACHIM a , DANA MUNTEAN a , LAURIAN VLASE a ,<br />

IOAN BÂLDEA b , DAN MIHU c , SORIN E. LEUCUŢA a<br />

ABSTRACT. A simple, reversed-phase high performance liquid chromatography<br />

method with mass spectrometric <strong>de</strong>tection (HPLC-MS/MS) was <strong>de</strong>veloped<br />

for <strong>de</strong>termination of an antiepileptic drug, phenytoin, in human plasma. The<br />

procedure involves a simple extraction step by mixing 0.2 ml plasma with<br />

0.6 ml methanol. After centrifugation, 1 µl of the supernatant was injected onto<br />

a Zorbax SB-C18 100 mm x 3 mm, 3.5 µm column, and eluted with a mobile<br />

phase consisting in a mixture of water containing 2 mM ammonium acetate<br />

and methanol 50:50 (v/v). Detection was in MRM mo<strong>de</strong>, using an electrospray<br />

positive ionization. The ion transition monitored was 253.1→(182.1+225.1). The<br />

method was evaluated in terms of linearity (between 2.0 µg/ml to 80.0 µg/ml),<br />

accuracy, precision, recovery, sensitivity. The lower limit of quantification<br />

was established at 2.0 µg/ml. The simple extraction procedure and short<br />

chromatographic runtime make the method suitable for therapeutic drug<br />

monitoring studies.<br />

Keywords: phenytoin, HPLC-MS/MS, human plasma<br />

INTRODUCTION<br />

Phenytoin (Figure 1) is wi<strong>de</strong>ly used in the treatment of epilepsy and is<br />

effective against all types of seisures. No drug has greater need for therapeutic<br />

drug concentration monitoring and individualized dosing than phenytoin. A good<br />

correlation usually is observed between the total concentration of phanytoin<br />

in plasma and the clinical effect. Therapeutic concentration of phenytoin is<br />

above 10 µg/ml [1]. Enzyme induction by phenytoin is well documented, even<br />

auto-induction by phenytoin should be consi<strong>de</strong>red during the treatment with<br />

phenytoin [2].<br />

a<br />

University of Medicine and Pharmacy “Iuliu Haţieganu”, Faculty of Pharmacy, Emil Isac 13,<br />

RO-400023 Cluj-Napoca, Romania, dana@tbs.ubbcluj.ro<br />

b<br />

Babeş-Bolyai” University, Faculty of Chemistry and Chemical Engineering, Arany Janos 11,<br />

RO-400028 Cluj-Napoca, Romania<br />

c<br />

University of Medicine and Pharmacy “Iuliu Haţieganu”, Faculty of Medicine, Emil Isac 13,<br />

RO-400023 Cluj-Napoca, Romania

MARCELA ACHIM, DANA MUNTEAN, LAURIAN VLASE, IOAN BÂLDEA, DAN MIHU, SORIN E. LEUCUŢA<br />

Plasma concentration monitoring is wi<strong>de</strong>ly used for the clinical management<br />

of epileptic patients receiving phenytoin [3]. To minimize toxicity, monitoring of<br />

plasma anticonvulsant levels is a part of the routine management of patients in<br />

many clinics. To the best of our knowledge, almost all of the methods that<br />

were applied for <strong>de</strong>termination of antieplileptic drugs in biological media are<br />

often chromatography, electrophoresis and immunoassay techniques [4,5].<br />

The aim of the present study was to <strong>de</strong>velop a fast LC-MS/MS method,<br />

able to quantify phenytoin in human plasma after a simple sample preparation<br />

by protein precipitation. The proposed method proved to be accurate and <strong>de</strong>spite<br />

of very simple sample preparation, showed high sensitivity.<br />

RESULTS AND DISCUSSION<br />

8<br />

C6H5<br />

C6H5<br />

O<br />

H<br />

N<br />

NH<br />

Figure 1. Molecular structure of phenytoin<br />

Figure 2 shows representative chromatograms of drug-free (blank)<br />

human plasma and a sample containing 2.0 µg/ml phenytoin (LOQ). No<br />

significant interference at the retention time of phenytoin (1.6 min) was<br />

observed, due to the specificity of the selected signal (Figure 3).<br />

Intens.<br />

6000<br />

4000<br />

2000<br />

0<br />

6000<br />

4000<br />

2000<br />

0<br />

CAL2__01.D: EIC 182.1; 225.1 ±MS2(253), Smoothed (0.3,1, GA)<br />

CAL2__02.D: EIC 182.1; 225.1 ±MS2(253), Smoothed (0.3,1, GA)<br />

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 Time [min]<br />

Figure 2. Chromatograms of a drug-free plasma sample (up) and LOQ plasma<br />

standard with 2.0 µg/ml phenytoin (down)<br />

O

NEW LC/MS/MS METHOD FOR THE QUANTIFICATION OF PHENYTOIN IN HUMAN PLASMA<br />

Intens.<br />

x105<br />

0.6<br />

0.4<br />

0.2<br />

0.0<br />

x104<br />

2.0<br />

1.5<br />

1.0<br />

0.5<br />

0.0<br />

182.1<br />

sp____02.d: +MS2(253.2), 540.8min (#2)<br />

225.1<br />

253.1<br />

sp____03.d: +MS2(253.2), 541.5min (#2)<br />

160 180 200 220 240 260 280 m/z<br />

Figure 3. Mass spectra of phenytoin. Full-scan spectrum (up) and<br />

MS/MS spectrum (down). The sum of ions with m/z 182.1 and 225.1<br />

was used for quantification<br />

The analyte <strong>de</strong>tection was ma<strong>de</strong> in MRM mo<strong>de</strong>, the ion transition<br />

monitored was m/z 253.1→(m/z 182.1 + m/z 225.1). This way, the <strong>de</strong>tection is<br />

more sensitive than in case based only on ion m/z 253.1 (Figure 3).<br />

The analyte carryover was verified using a blank injection ma<strong>de</strong> right<br />

after an injection of the most elevated concentration level from calibration<br />

curve. No interference at retention time of analyte due to carryover was<br />

observed.<br />

The mean calibration curve y = a(±S.D.)x + b(±S.D.), with S.D. standard<br />

<strong>de</strong>viation, was: y = (59590.4±1971.9)x – (10490.5±2501.6), N = 8 calibration<br />

points, n = 5 <strong>de</strong>terminations for each calibration point. The residuals had no<br />

ten<strong>de</strong>ncy of variation with concentration. The applied calibration curve mo<strong>de</strong>l<br />

proved to be accurate over the concentration range 2 – 80 µg/ml, with a<br />

correlation coefficient grater than 0.998 (Figure 4).<br />

The intra-day precision was <strong>de</strong>termined from replicate analysis of<br />

samples containing phanytoin at four different concentrations covering the low,<br />

medium and higher ranges of calibration curve (Table 1), in good agreement to<br />

international regulations regarding bioanalytical methods validation [6-8].<br />

The intra-day precision and accuracy ranged from 1.9% to 9.5% and 3.7%<br />

to 10% respectively.<br />

9

MARCELA ACHIM, DANA MUNTEAN, LAURIAN VLASE, IOAN BÂLDEA, DAN MIHU, SORIN E. LEUCUŢA<br />

10<br />

Figure 4. Calibration curve for phenytoin<br />

Table 1. Intra-day precision, accuracy and recovery for phenytoin (n = 5)<br />

cnominal<br />

(µg/ml)<br />

Mean cfound<br />

(µg/ml) (± S.D.)<br />

C.V. % Bias %<br />

Recovery %<br />

(± S.D.)<br />

2.0 2.07 (0.2) 9.5 3.7 106.5 (10.5)<br />

5.0 5.50 (0.10) 1.9 10.0 100.3 (1.9)<br />

32.0 34.87 (1.94) 5.6 9.0 102.4 (5.7)<br />

64.0 67.60 (3.74) 5.5 5.6 101.1 (5.6)<br />

The intra-day precision and accuracy were <strong>de</strong>termined by analyzing<br />

in five different days samples that have the same concentration, at lower,<br />

medium and higher levels from calibration curve. The precision ranged from<br />

3.5% to 10.1% and accuracy from 1.5% to 7.2 % (Table 2):<br />

Table 2. Inter-day precision, accuracy and recovery for phenytoin (n = 5)<br />

cnominal<br />

(µg/ml)<br />

Mean cfound<br />

(µg/ml) (± S.D.)<br />

C.V. % Bias %<br />

Recovery %<br />

(± S.D.)<br />

2.0 2.03 (0.20) 10.1 1.5 121.1 (35.3)<br />

5.0 5.36 (0.21) 4.0 7.2 97.3 (9.1)<br />

32.0 33.10 (1.16) 3.5 3.4 101.4 (5.6)<br />

64.0 66.32 (2.87) 4.3 3.6 99.1 (4.6)

NEW LC/MS/MS METHOD FOR THE QUANTIFICATION OF PHENYTOIN IN HUMAN PLASMA<br />

Un<strong>de</strong>r the experimental conditions used, the lower limit of quantification<br />

(LOQ) was of 2 µg/ml phenytoin. LOQ is the lowest amount of analyte<br />

which can be measured with accuracy and precision less than 20%.<br />

CONCLUSIONS<br />

A simple, sensitive, accurate and precise HPLC/MS/MS method for<br />

<strong>de</strong>termination of phenytoin in human plasma using a simple single-step<br />

extraction procedure is reported. Another advantage of the method is the<br />

short chromatographic runtime of only 2.1 min. The method is suitable for<br />

therapeutic drug monitoring studies and can also be used for pharmacokinetic<br />

studies conducted on healthy volunteers [9-13].<br />

EXPERIMENTAL SECTION<br />

Reagents<br />

Phenytoin, methanol, ammonium acetate, were purchased from Merck<br />

(Merck KgaA, Darmstadt, Germany). Solvents used were HPLC gra<strong>de</strong> and<br />

all other chemicals were of analytical gra<strong>de</strong>. Distilled, <strong>de</strong>ionised water was<br />

produced by a Direct Q-5 Millipore (Millipore SA, Molsheim, France) water<br />

system. The drug-free human plasma was supplied by the Local Bleeding<br />

Centre Cluj-Napoca, Romania.<br />

Preparation of standard solutions<br />

A stock solution containing 10 mg/ml phenytoin was prepared in<br />

methanol. A working solution of 200 µg/ml was prepared by diluting the<br />

appropriate volume of stock solution with plasma. Than this was used to<br />

spike different volumes of drug-free plasma, providing finally eight plasma<br />

standards with concentration between 2.0 and 80.0 µg/ml. Quality control<br />

samples (QC) of 5.0, 32.0, and 64.0 µg/ml were prepared by diluting specific<br />

volumes of working solution with plasma and were used to evaluate precision<br />

and accuracy of the method.<br />

Chromatographic and mass spectrometry systems and conditions<br />

The HPLC system was an 1100 series mo<strong>de</strong>l (Agilent Technologies)<br />

consisted in a binary pump, an in-line <strong>de</strong>gasser, an autosampler, a column<br />

thermostat and an Ion Trap VL mass spectrometer <strong>de</strong>tector (Bruckner Daltonics<br />

GmbH, Germany). Chromatograms were processed using QuantAnalysis<br />

Software. The <strong>de</strong>tection of phenytoin was in MRM (MS/MS) mo<strong>de</strong>, using an<br />

electrospray positive ionization (ESI positive). The ion transitions monitored<br />

was: m/z 253.1→(m/z 182.1 + m/z 225.1). Chromatographic separation was<br />

performed at 45ºC on a Zorbax SB-C18 100 mm x 3 mm, 3.5 µm column<br />

(Agilent Technologies), protected by an inline filter.<br />

11

MARCELA ACHIM, DANA MUNTEAN, LAURIAN VLASE, IOAN BÂLDEA, DAN MIHU, SORIN E. LEUCUŢA<br />

Mobile phase<br />

The mobile phase consisted in a mixture of water containing 2 mM<br />

ammonium acetate and methanol (50:50 v/v). It was always freshly prepared<br />

and was <strong>de</strong>gassed before elution for 10 min in am Elma Transsonic 700/H<br />

(Singen, Germany) ultrasonic bath. The pump <strong>de</strong>livered the mobile phase at a<br />

flow rate of 1 ml/min.<br />

Sample preparation<br />

Plasma samples were prepared as follows in or<strong>de</strong>r to be<br />

chromatographically analyzed: in an Eppendorf tube (max 1.5 ml), 0.2 ml<br />

plasma and 0.6 ml methanol were ad<strong>de</strong>d. The tube was vortex-mixed for 10 s<br />

(Vortex Genie 2, Scientific Industries) and centrifuged for 6 min at 5000 rpm<br />

(2-16 Sartorius centrifuge, Ostero<strong>de</strong> am Harz, Germany). The supernatant was<br />

transferred to an autosampler vial and 1 µl was injected into the HPLC system.<br />

Validation<br />

As a first step of method validation [6-8], specificity was verified<br />

using six different plasma blanks obtained from healthy volunteers who had<br />

not previously taken any medication.<br />

The concentration of the analyte was <strong>de</strong>termined automatically by the<br />

instrument data system. The calibration curve mo<strong>de</strong>l was y = ax + b, weight<br />

1/y linear response, where y-peak area and x-concentration. Distribution of the<br />

residuals (% difference of the back-calculated concentration from the nominal<br />

concentration) was investigated. The calibration mo<strong>de</strong>l was accepted, if the<br />

residuals were within ±20% at the lower limit of quantification (LOQ) and<br />

within ±15% at all other calibration levels and at least 2/3 of the standards<br />

meet this criterion, including highest and lowest calibration levels.<br />

The intra-day and inter-day precision (expressed as coefficient of<br />

variation, CV%) and accuracy (expressed as relative difference between<br />

obtained and theoretical concentration, bias%) of the assay procedure were<br />

<strong>de</strong>termined by analysing on the same day five different samples at each of<br />

the lower (5.0 µg/ml), medium (32.0 µg/ml) and higher (64.0 µg/ml) levels of<br />

the consi<strong>de</strong>red concentration range and one different sample of each at five<br />

different occasions, respectively.<br />

The recovery of phenytoin was analyzed at each of the three<br />

concentration levels mentioned above, e.g. lower, medium and higher level,<br />

and also at the quantification limit, by comparing the peack area response<br />

of spiked plasma samples with the response of standards prepared in water<br />

with the same concentration of ivabradine as the plasma samples, all these<br />

prepared as stated in section “Sample preparation”.<br />

ACKNOWLEDGMENTS<br />

This work was supported by Grant CEEX-ET co<strong>de</strong> 121, contract no.<br />

5860/2006, financed by CNCSIS Romania.<br />

12

NEW LC/MS/MS METHOD FOR THE QUANTIFICATION OF PHENYTOIN IN HUMAN PLASMA<br />

REFERENCES<br />

1. Z. Rezaei, B. Hemmateenejab, S. Khabnadi<strong>de</strong>h, M. Gorgin, Talanta, 2005, 65, 21.<br />

2. M. Cheety, R. Miller, M. A. Seymour, Ther. Drug Monit., 1998, 20, 60.<br />

3. K. M. Patil, S. L. Bodhankar, J. Pharm. Biomed. Analysis, 2005, 39, 181.<br />

4. D. J. Speed, S. J. Dickson, E. R. Cairus, N. D. Kim, J. Anal. Toxicol., 2000, 24, 685.<br />

5. M. E. Queiroz, S. M. Silvia, D. Carralho, F. M. Lancas, J. Chroma. Sci., 2002,<br />

40, 219.<br />

6. The European Agency for the Evaluation of Medicinal Products. Note for Guidance<br />

on the Investigation of Bioavailability and Bioequivalence, London, UK, 2001<br />

(CPMP/EWP/QWP/1401/98).<br />

7. U. S. Department of Health and Human Services, Food and Drug Administration,<br />

Center for Drug Evaluation and Research. Guidance for Industry. Bioavailability<br />

and Bioequivalence Studies for Orally Administrated Drug Products – General<br />

Consi<strong>de</strong>rations, Rockville, USA, 2003, http://www.fda.gov/c<strong>de</strong>r/guidance/in<strong>de</strong>x.htm.<br />

8. U. S. Department of Health and Human Services, Food and Drug Administration,<br />

Guidance for Industry – Bioanalytical Method Validation, 2001.<br />

9. L. Vlase L, S. E. Leucuta, S. Imre, Talanta, 2008, 75, 1104.<br />

10. L. Vlase, A. Leucuta, D. Farcau D, M. Nanulescu, Biopharma. Drug Dispos., 2006,<br />

27, 285.<br />

11. L. Vlase, S. Imre, D. Muntean, S. E. Leucuta, J.Pharma. Biomed. Analysis, 2007,<br />

44(3), 652.<br />

12. L. Vlase, D. Muntean, S. E. Leucuta, I. Bal<strong>de</strong>a, Studia Univ. Babes-Bolyai Chemia,<br />

2009, 54, 43.<br />

13. A. Butnariu, D. S. Popa, L. Vlase, M. Andreica, D. Muntean, S. E. Leucuta, Revista<br />

Romana De Medicina De Laborator, 2009, 15, 7.<br />

13

STUDIA UNIVERSITATIS BABEŞ-BOLYAI, CHEMIA, LIV, 3, 2009<br />

STUDIES ON WO3 THIN FILMS PREPARED BY<br />

DIP-COATING METHOD<br />

ECATERINA BICA a,b , LAURA ELENA MUREŞAN a , LUCIAN BARBU-<br />

TUDORAN c , EMIL INDREA d , IONEL CĂTĂLIN POPESCU b AND<br />

ELISABETH-JEANNE POPOVICI a<br />

ABSTRACT. WO3 films obtained by dip-coating technique were investigated<br />

to evi<strong>de</strong>nce the properties of tungsten trioxi<strong>de</strong> films for water splitting applications.<br />

The <strong>de</strong>position solution containing peroxo-tungstic acid was prepared by<br />

sol-gel method. The films were <strong>de</strong>posited on conductive glass substrates and<br />

were annealed at 250-550 0 C. The properties of WO3 films were investigated<br />

by UV-Vis Spectroscopy, X-Ray diffraction (XRD) and Scanning Electron<br />

Microscopy (SEM).<br />

Keywords: Tungsten trioxi<strong>de</strong> films; ITO support; Dip-coating.<br />

INTRODUCTION<br />

Tungsten oxi<strong>de</strong> (WO3) is a wi<strong>de</strong> – band gap semiconductor of great<br />

interest because of its applications in optoelectronics, catalysis and environmental<br />

engineering [1-3]. On the other hand, it was <strong>de</strong>monstrated that WO3 thin films<br />

exhibits chemical sensing properties such as H2S, NOx, [4-7]. Moreover, WO3<br />

thin films electro<strong>de</strong>s are reversible and have fast electrochromic properties [8].<br />

Tungsten oxi<strong>de</strong> films can be synthesized by several physical and<br />

chemical routes such as sputtering [9], acid precipitation method [10] and<br />

sol-gel processing [11-14].<br />

Application of tungsten trioxi<strong>de</strong> (WO3) thin films strongly <strong>de</strong>pends on<br />

morpho-structural characteristics that are regulated during the synthesis.<br />

The aim of this study is to obtain high quality WO3 thin films for photocatalysis<br />

and water splitting applications. The performed study presents the<br />

influence of some preparative conditions on the morpho-structural characteristics<br />

a<br />

Babeş-Bolyai University, “Raluca Ripan” Institute for Research in Chemistry, Fantanele 30,<br />

Cluj-Napoca, Romania, ebica@chem.ubbcluj.ro<br />

b<br />

Babeş-Bolyai University, Faculty of Chemistry and Chemical Engineering, Arany Janos 11,<br />

Cluj-Napoca, Romania<br />

c<br />

Babeş-Bolyai University, Electronic Microscopy Centre, Clinicilor 5-7, Cluj-Napoca, Romania<br />

d<br />

National Institute for R&D of Isotopic and Molecular Technologies, Donath 30, Cluj-Napoca,<br />

Romania

16<br />

E. BICA, L.E. MUREŞAN, L. BARBU-TUDORAN, E. INDREA, I.C. POPESCU, E.-J. POPOVICI<br />

of WO3 films, and put in evi<strong>de</strong>nce that the quality of the dip-coating solution<br />

and the thermal treatment play an important role on the properties of conductive<br />

glass supported WO3 films.<br />

RESULTS AND DISCUSSIONS<br />

WO3/ITO/Glass/WO3 heterostructures containing tungsten oxi<strong>de</strong> thin<br />

films were obtained using the dip-coating method, from peroxo-tungstic acid<br />

sol. The multilayer technique was used to prepare films with variable thickness<br />

whereas the thermal treatment was performed at 250 - 550°C (Table 1).<br />

Film thickness varies between 35 and 135 nm, in parallel with the number of<br />

dip coating <strong>de</strong>position cycles; it seems that the thickness is not influenced<br />

by the annealing regime.<br />

Table 1. Synthesis conditions of WO3 thin films prepared from<br />

peroxo-tungstic acid sol (dip-coating method)<br />

Sample co<strong>de</strong> Thermal<br />

treatment<br />

( 0 C)<br />

Number of<br />

layers<br />

WO3 weight<br />

(g)<br />

Film thickness<br />

(nm)<br />

R4 I1 350 1 0.55 x 10 -3<br />

35<br />

R4 I2 350 2 0.94 x 10 -3 60<br />

R4 I3 350 3 1.62 x 10 -3 95<br />

R4 I4 350 4 1.97 x 10 -3 125<br />

R4 I5 350 5 2.20x 10 -3 135<br />

R3.1 I2 250 1 0.30 x 10 -3 20<br />

R3.1 I3 350 1 0.56 x 10 -3 35<br />

R3.1 I4 550 1 0.50 x 10 -3 35<br />

In or<strong>de</strong>r to establish the optimal thermal treatment regime for WO3 thin<br />

films, the peroxo-tungstic acid (PTA) precursor was investigated by thermal<br />

analysis.<br />

Figure 1. TGA and DTG curves of<br />

PTA precursor.<br />

Figure 2. FT-IR spectrum of<br />

PTA precursor.

STUDIES ON WO3 THIN FILMS PREPARED BY DIP-COATING METHOD<br />

The TGA and DTG curves of PTA precursor indicate three most<br />

important weight loss steps i.e. (1) -14.92% at 20-200°C (removal of physical<br />

adsorbed water and alcohol); (2) -3.35% at 235-345 °C (removal of H2O2, i.e.<br />

peroxo-tungstic acid <strong>de</strong>composition) and (3) -1.05% at 345-405 °C (removal of<br />

chemically bon<strong>de</strong>d water i.e. tungstic acid <strong>de</strong>composition) (Fig.1).The weight<br />

loss steps are accompanied by weak endo- and exo- thermal effects.<br />

The FT-IR spectrum of the precursor pow<strong>de</strong>r (that corresponds to<br />

the as- <strong>de</strong>posited WO3 film), illustrates the hydrated and the hydroxilated<br />

nature of the WO3 <strong>de</strong>posit (Figure 2). Water presence is signalled by the<br />

3418 cm -1 {ν(OH)} and 1617 cm -1 {δ(HOH)} bands. Because the ν(OH) appears<br />

as a single featureless band, it is difficult to isolate the in<strong>de</strong>pen<strong>de</strong>nt contributions<br />

from structural water, hydroxyl groups, hydrogen bon<strong>de</strong>d and adsorbed species.<br />

Despite the complexity of the W-O stretching bands region (400-1000cm -1 ), it<br />

gives important information about the precursor. Besi<strong>de</strong>s the specific ν(W-Ointra-W)<br />

and ν(W-Ointer-W) bridging stretches ( 863-823 cm -1 and 687 -625 cm -1 ), the<br />

stretching vibrations of W(O2) and W-O could be noticed (959 cm -1 and<br />

553 cm -1 ), thus indicating the formation of [(O2)2W(O).O.W(O)(O2)2] 2- complex<br />

associated with the peroxo-tungstic acid [15-17].<br />

The optical properties of WO3 films were evaluated from UV-Vis<br />

transmission (Figure 3) and reflection (Figure 4) spectra.<br />

a. b.<br />

Figure 3. Transmission spectra of WO3 films obtained in different conditions:<br />

a) multilayer films treated at 350°C; b) monolayer films annealed at 250 – 550°C.<br />

The monolayer WO3 film (R4I1) shows an almost constant transmittance<br />

of about 80% on the entire visible domain. As expected, the multilayer films<br />

R4I2, R4I3, R4I4 and R4I5 have a lower transmittance (50 -80 %) as compared<br />

with the monolayer heterostructures. The absorption edge shifts from 300 nm<br />

to 315 nm as the film thickness increases (Figure 3a).<br />

17

18<br />

E. BICA, L.E. MUREŞAN, L. BARBU-TUDORAN, E. INDREA, I.C. POPESCU, E.-J. POPOVICI<br />

The thermal treatment <strong>de</strong>termines the <strong>de</strong>creases of the transmittance,<br />

in parallel with the temperature increase (Figure 3b). The thermal treatment<br />

also produces the color change of transparent films from colorless to yellowpale,<br />

thus suggesting some morpho-structural variation.<br />

Figure 4. Reflectance spectra for the multilayer WO3 film (R4I5)<br />

measured on ITO face.<br />

The specular reflectance (8 0 -0 0 ) spectrum is obtained by the difference<br />

between the total reflectance (8 0 ) and diffuse reflectance (0 0 ) spectra. The<br />

reflection maximum is situated in the blue range of the spectral domain.<br />

In or<strong>de</strong>r to <strong>de</strong>termine the optical energy band gap of WO3 films, the<br />

Bar<strong>de</strong>en equation [18] was used:<br />

r<br />

( α hν ) = A(<br />

hν<br />

− Eg<br />

)<br />

(1)<br />

where: α is the absorption coefficient, Eg is the energy band gap of the<br />

semiconductor, h is the Plank’s constant, A is a parameter that <strong>de</strong>pends<br />

on the transition probability and r is a number that characterises the transition<br />

process. Depending on the semiconductor type, r values could be: r =2 and<br />

2/3 for direct allowed and forbid<strong>de</strong>n transitions, respectively, and r=1/2 and<br />

1/3 for indirect allowed and forbid<strong>de</strong>n transitions, respectively [18]. The<br />

absorption coefficient α was calculated using the formula (2):<br />

exp( − α d ) = T<br />

(2)<br />

where:<br />

d is the film thickness (see table 1), and T is the measured transmittance [19].

STUDIES ON WO3 THIN FILMS PREPARED BY DIP-COATING METHOD<br />

From the transmittance spectra of WO3 films (calculated without<br />

substrate), the band gap energy (Eg) was evaluated using the Tauc plot’s,<br />

by extrapolation of the straight line in the plot (αhν) 1/2 vs hν (Figure 5).<br />

The <strong>de</strong>termined band gap of dip-coated WO3 films varies between<br />

2.9 and 3.2eV, in agreement with the literature data [20, 21]. The plot feature<br />

illustrates that the as obtained WO3 films behaves as an indirect semiconductor<br />

between about 3.3 and 4.0 eV [20].<br />

Figure 5. Plot of (αhν) 1/2 vs hν for WO3 films.<br />

The X-ray diffraction indicates that peroxotungstic acid precursor<br />

is amorphous, whereas the WO3 films <strong>de</strong>posited on conductive glass are<br />

crystallized (Figure 6).<br />

Figure 6. XRD patterns for PTA precursor and the corresponding<br />

heterostructure WO3/ITO/Glass/WO3 (film R4I5).<br />

19

20<br />

E. BICA, L.E. MUREŞAN, L. BARBU-TUDORAN, E. INDREA, I.C. POPESCU, E.-J. POPOVICI<br />

The XRD pattern contains the characteristic diffraction lines of the<br />

conductive substrate i<strong>de</strong>ntified as being cubic SnO2 (JCPDS 33-1374) and<br />

the diffraction lines of monoclinic WO3 (JCPDS 72-0677). One can be noted<br />

that, due to the crystalline structure of the substrate, the growth of WO3 films<br />

seams to be oriented alongsi<strong>de</strong> the (200) reflection plane.<br />

The SEM images illustrate that WO3 film consists on nano-metric<br />

particles that creates a homogeneous surface (Figure 7). A small ten<strong>de</strong>ncy<br />

toward the increase of cracks number with the number of layers could be<br />

noticed. More than that, the increase of the annealing temperature from<br />

350 0 C to 550 0 C, leads to the formation of larger crakes in the WO3 film.<br />

a b<br />

c<br />

Figure 7. SEM images of WO3 film surface: (a) one layer (350°C)<br />

(b) five layers (350 0 C) and (c) one layer (550 0 C).<br />

CONCLUSIONS<br />

Homogeneous and adherent WO3 thin films were obtained by dip<br />

coating technique, on conductive glass substrates from aqueous solution of<br />

peroxotungstic acid obtained by dissolving fresh prepared tungstic acid into<br />

hydrogen peroxi<strong>de</strong> solution. Film thickness increases from ~35 to 135 nm<br />

as the number of dip coating <strong>de</strong>position cycles increases.

STUDIES ON WO3 THIN FILMS PREPARED BY DIP-COATING METHOD<br />

Thermal analysis and FT-IR spectroscopy suggest that the precursor<br />

isolated from the colloidal dip-coating solution, corresponds to peroxotungstic<br />

acid.<br />

The optical transmittance of WO3 films is influenced by the number<br />

of layers. In this respect, the WO3/ITO/Glass/WO3 monolayer has a good<br />

transmittance between 450-1000 nm and it <strong>de</strong>creases as the film thickness<br />

increases. The thermal treatment <strong>de</strong>teriorates the transmission of WO3 films.<br />

The calculated values of the optical band gap energy (Eg) vary between 2.9 and<br />

3.2eV, in accordance with the literature data. The reflectance of the as obtained<br />

WO3 films is dominant in the blue domain of visible spectra.<br />

SEM images put in evi<strong>de</strong>nce that WO3 film morphology <strong>de</strong>pends on<br />

the layer number as well as the thermal treatment that both <strong>de</strong>termine the<br />

number of cracks and their size.<br />

EXPERIMENTAL SECTION<br />

Preparation. In or<strong>de</strong>r to obtain WO3 thin films, the sol-gel solution<br />

was prepared starting from an 0.5M aqueous solution of sodium tungstate<br />

(Na2WO4 ⋅ 2H2O – Aldrich), which was passed through a cationic exchange<br />

resin (~2 ml/min) to yield a yellow pale solution of H2WO4. The freshly prepared<br />

tungstic acid was dissolved in hydrogen peroxi<strong>de</strong> (H2O2, Merck) and the as<br />

obtained peroxo-tungstic acid (PTA) was stabilized with ethanol addition. In the<br />

meantime, the conductive glass substrates (30x30x1mm, Optical Filters Ltd.)<br />

were cleaned in acidic bath and alcohol, and dried. From this peroxo-tungstic<br />

acid sol, WO3 films were <strong>de</strong>posited on the conductive support (notated ITO),<br />

by dip-coating method, using an withdrawal speed of 4cm/min. The films were<br />

dried at 110 0 C, and annealed at 350-550 0 C for 30 minutes, in air. Several<br />

dipping-drying cycles were used to consolidate the WO3 structure.<br />

Sample characterization. The PTA precursor (dried at ~70°C) was<br />

investigated by thermal analysis (Mettler Toledo TGA/SDTA851; heating<br />

rate 5 0 C/min; nitrogen atmosphere) and FT-IR Spectroscopy (JASCO 610<br />

Spectrometer; KBr pellets technique).<br />

UV-Vis spectroscopy (UNICAM Spectrometer UV4, with RSA-UC-40<br />

integrating sphere accessory), X-ray diffraction (DRON 3M Diffractometer,<br />

CoKα radiation) and scanning electronic microscopy (JEOL-JSM 5510LV<br />

Microscope Au coated samples) were used to characterize the WO3 thin films.<br />

The films thickness was estimated by micro-weighing method (Saltec Balance).<br />

ACKNOWLEDGEMENTS<br />

This work was supported by the Romanian Ministry of Education,<br />

Research and Innovation (Project: 71-047).<br />

21

22<br />

E. BICA, L.E. MUREŞAN, L. BARBU-TUDORAN, E. INDREA, I.C. POPESCU, E.-J. POPOVICI<br />

REFERENCES<br />

1. J. Luo, M. Hepel, Electrochim. Acta, 2001, 46, 2913.<br />

2. S. Wang, X. Shi, G. Shao, S. Duan, H. Yang, T. Wang, J. Phys. Chem. Solid.,<br />

2008, 69, 2396.<br />

3. J.-C. Yang, P. K. Dutta, Sensors and Actuators, 2008, 136, 523.<br />

4. A. K. Chawla, S. Singhal, H. O. Gupta, R. Chandra, Thin Solid Films, 2008, 517,<br />

1042<br />

5. C. Santato, M. Odziemkowski, M. Ullman, J. Augustinski, J. Am. Chem. Soc.,<br />

2001, 123, 10639.<br />

6. A. I. Gavrilyuk, Electrochim. Acta, 1999, 44, 3027.<br />

7. P. M. S. Monk, R. D. Partridge, R. Janes, C. G. Granqvist, Solar Energ. Mater.<br />

Solar Cell., 2000, 60, 201-262.<br />

8. G. Leftheriotis, P. Yianoulis, Solid State Ionics, 2008, 179, 2192.<br />

9. S. Supothina, P. Seeharaj, S.Yoriya, M. Sriyudthsak, Ceramics International,<br />

2007, 33, 931.<br />

10. M. Deepa, R. Sharma, A. Basu, S. A. Agnihotry, Electrochim. Acta, 2005, 50, 3545.<br />

11. Y. Suda, H. Kawasaki, T. Ohshima, Y. Yagyuu, Thin Solid Films, 2008, 516, 4397.<br />

12. B. Yang, P. R. F. Barnes, W. Bertram, V. Luca, J. Mater. Chem., 2007, 17, 2722.<br />

13. L. Muresan, E. J. Popovici, A. R. Tomsa, L. Silaghi-Dumitrescu, L. Barbu-Tudoran,<br />

E. Indrea, J. Optoelec. Adv. Mater., 2008, 10, 2261.<br />

14. K. Huang, J. Jia, Q. Pan, F. Yang, D. He, Physica B, 2007, 396, 164.<br />

15. B. Pecquenard, H. Lecacheux, J. Livage, C. Julien, J. Solid State Chem., 1998,<br />

135, 159.<br />

16. A. Novinrooz, M. Sharbatdaran, H. Noorkojouri, Central European J. Phys, 2005,<br />

3, 456.<br />

17. M. F. Daniel, B. Desbat, J. Solid State Chem., 1992, 67, 235.<br />

18. M. G. Hutchins, O. Abu-Alkhair, M. M. El-Nahass, K. Abd El-Hady, Mater.Chem.<br />

Phys, 2006, 98, 401.<br />

19. P. Sharma, V. Sharma, S. C. Katyal, Chalcogeni<strong>de</strong> Letters, 2006, 3, 73.<br />

20. K. J. Lethy, D. Beena, R. V. Kumar, V. P. Maha<strong>de</strong>van Pillai, V. Ganesan, V. Sathe,<br />

Applied Surface Sci., 2008, 254, 2369.<br />

21. M. Deepa, A. K. Srivastava, M. Kar, S. A. Agnitory, J. Phys. D: Applied Phys.,<br />

2006, 39, 1885.

STUDIA UNIVERSITATIS BABEŞ-BOLYAI, CHEMIA, LIV, 3, 2009<br />

PREPARATION AND CHARACTERIZATION OF MANGANESE<br />

DOPED ZINC SULPHIDE NANOCRYSTALLINE POWDERS<br />

WITH LUMINESCENT PROPERTIES<br />

ADRIAN-IONUŢ CADIŞ a,b , ADRIAN RAUL TOMŞA a , ECATERINA BICA a ,<br />

LUCIAN BARBU-TUDORAN c , LUMINIŢA SILAGHI-DUMITRESCU b ,<br />

ELISABETH-JEANNE POPOVICI a<br />

ABSTRACT. Manganese-doped zinc sulphi<strong>de</strong> nanocrystalline pow<strong>de</strong>rs have<br />

been synthesized from zinc-manganese acetate and sodium sulphi<strong>de</strong>, in<br />

aqueous solution containing methacrylic acid. Precipitation was performed at<br />

low temperature, using the sequential reagent addition technique. Different Mn 2+<br />

concentrations have been used to control the optical properties of ZnS:Mn 2+<br />

nanoparticles. All samples were characterized by thermal analysis (TGA), infrared<br />

absorption spectroscopy (FT-IR), photoluminescence spectroscopy (PL),<br />

scanning (SEM) and transmission electron microscopy (TEM). A correlation<br />

between the preparation conditions and optical and morphological characteristics<br />

of ZnS:Mn 2+ pow<strong>de</strong>rs was established.<br />

Keywords: Zinc sulphi<strong>de</strong>, Mn-doped nanoparticles, Photoluminescence<br />

INTRODUCTION<br />

Nanocrystalline materials have been of interest for more than 25 years<br />

[1-3]. The main cause is in their unusual properties based on the high<br />

concentration of atoms at interfacial structure and the relative simple ways of<br />

their preparation. Recently, nanoparticles of zinc sulphi<strong>de</strong> have become the<br />

subject of intense investigations due to their potential applications in catalysis,<br />

sensors, nonlinear optics and molecular electronics [4-5]. At the same time,<br />

the synthesis of zinc sulphi<strong>de</strong> (ZnS) particles with uniform morphology and<br />

narrow size distribution is still in the future and need to be further studied.<br />

a<br />

”Raluca Ripan” Institute for Research in Chemistry, “Babes- Bolyai” University, 30 Fântânele,<br />

RO-400294 Cluj-Napoca, Romania, cadisadi@chem.ubbcluj.ro<br />

b<br />

Faculty of Chemistry and Chemical Engineering, “Babes-Bolyai” University, 11 Arany Janos,<br />

RO-400028 Cluj-Napoca, Romania<br />

c<br />

Electronic Microscopy Centre, “Babes-Bolyai” University, 5-7 Clinicilor, RO-400006 Cluj-Napoca,<br />

Romania

A.-I. CADIŞ, A.R. TOMŞA, E. BICA, L. BARBU-TUDORAN, L. SILAGHI-DUMITRESCU, E.-J. POPOVICI<br />

The increasing interest in these materials has lead to the <strong>de</strong>velopment of<br />

a variety of chemical routes to prepare nanoparticles, including sputtering [6],<br />

ultrasound irradiation [7], co-evaporation [8], sol–gel method [9], solid-state<br />

reaction [10], gas-phase con<strong>de</strong>nsation [11], liquid-phase chemical precipitation [12],<br />

ion complex transformation [13], microwave irradiation [14] and biological<br />

synthesis [15]. From all these works, it has been found that particle size<br />

and luminescent properties of ZnS pow<strong>de</strong>rs <strong>de</strong>pend strongly on the specific<br />

preparation method and the applied experimental conditions.<br />

This paper is the first in the series <strong>de</strong>dicated to the comparative<br />

investigation of luminescent and morphostructural properties of nanocrystalline<br />

ZnS:Mn pow<strong>de</strong>rs obtained by different synthesis routes. In this respect, attempts<br />

to obtain manganese doped ZnS nanoparticles are performed by precipitation,<br />

using the sequential reagent addition technique (SeqAdd). In or<strong>de</strong>r to control the<br />

particle morphology and size, methacrylic acid is used as passivating agent. A<br />

systematic investigation on the influence of Mn-concentration on the photoluminescence<br />

properties of nanocrystalline ZnS:Mn 2+ is reported. A variety<br />

of methods including scanning electron microscopy (SEM), Fourier transform<br />

infrared spectroscopy (FTIR), and photoluminescence spectroscopy (PL) were<br />

used to characterise the ZnS:Mn nanoparticles.<br />

RESULTS AND DISCUSSION<br />

The goal of our study was to obtain luminescent manganese doped<br />

zinc sulphi<strong>de</strong> ZnS:Mn 2+ nanoparticles with controlled particle dimensions. In<br />

this purpose, attempts were ma<strong>de</strong> to prepare ZnS:Mn 2+ pow<strong>de</strong>rs, starting from<br />

Zn-Mn acetate mixture and sodium sulphi<strong>de</strong>, in presence of methacrylic acid as<br />

particle size regulating agent. Precipitation was performed at low temperature,<br />

using SeqAdd technique. Zn-Mn acetate mixtures with variable compositions<br />

were used to obtain ZnS nanoparticles with variable Mn-doping level. The as<br />

obtained precipitation product can be consi<strong>de</strong>red as Zn-Mn double sulphi<strong>de</strong><br />

and the chemical process can be <strong>de</strong>scribed by the overall equation:<br />

In this manner, a series of 6 samples was prepared from mixture<br />

containing the following Mn/(Zn+Mn) ratios: 0 mol% (CAI17), 5.6 mol% (CAI19),<br />

11.0 mol% (CAI73), 16.4 mol% (CAI21), 21.8 mol% (CAI20) and 25.0 mol%<br />

(CAI77). Mention has to be ma<strong>de</strong> that, the amount of incorporated Mn is<br />

about 0.1% of its concentration, as illustrated by the ICP measurements.<br />

24

PREPARATION AND CHARACTERIZATION OF MANGANESE DOPED ZINC SULPHIDE …<br />

The as prepared ZnS pow<strong>de</strong>rs show a high capacity to absorb anionic<br />

impurities from the precipitation medium, as exemplified by thermal analysis<br />

and FTIR spectroscopy.<br />

The thermal behaviour of ZnS:Mn 2+ pow<strong>de</strong>rs was investigated in the<br />

25-1100ºC range, un<strong>de</strong>r N2 flow. Thermogravimetric (TGA) and differential<br />

thermogravimetric (DTG) curves of ZnS pow<strong>de</strong>r are <strong>de</strong>picted in Figure 1.<br />

There are four major weight loss steps i.e. (1) - 7.2% at 20-188°C; (2) -9.9%<br />

at 188-300°C; (3) - 9.9 % at 300-850°C and (4) over 850°C that could be<br />

associated with: (1) removal of physically adsorbed water; (2) thermal dissociation<br />

of the acetate species adsorbed on the particle surface; (3) thermal dissociation<br />

and removal of organic compound and (4) sublimation of zinc sulphi<strong>de</strong>,<br />

facilitated by the N2 flow.<br />

Figure 1. TGA and DTG curves for<br />

ZnS:Mn pow<strong>de</strong>r (CAI21)<br />

Figure 2. FT-IR spectrum of ZnS:Mn 2+<br />

sample (CAI21)<br />

The FT-IR spectrum of ZnS:Mn 2+ pow<strong>de</strong>r show the characteristic<br />

vibration bands for metal acetate, water and methacrylic acid, ionic or molecular<br />

compounds adsorbed from the precipitation medium (Fig.2.). The most<br />

important absorption bands are assigned as follows: hydroxyl groups (O-H)<br />

(between 3000 and 3600 cm -1 ), CH3 bending mo<strong>de</strong>s (950-1100 and 2800-<br />

3000 cm -1 ), H2O and COO group (between1300 and 1600 cm -1 ) and C=C<br />

and =CH groups (1000-1200 cm -1 ) [16].<br />

Mention has to be ma<strong>de</strong> of the large surface area of pow<strong>de</strong>rs<br />

<strong>de</strong>termines a high amount of anionic species to be adsorbed from the<br />

precipitation medium. In spite of the fact that all samples were carefully<br />

washed and centrifuged, the contaminants removal can not be completely<br />

done, due to the ZnS hydrolysis.<br />

The as prepared manganese doped zinc sulphi<strong>de</strong> pow<strong>de</strong>rs show<br />

photoluminescence properties un<strong>de</strong>r ultraviolet excitation. Figure 3 shows<br />

the emission spectra (λexc = 335 nm) for samples synthesised from acetate<br />

25

A.-I. CADIŞ, A.R. TOMŞA, E. BICA, L. BARBU-TUDORAN, L. SILAGHI-DUMITRESCU, E.-J. POPOVICI<br />

mixtures with different Mn 2+ concentrations. Nanocrystalline ZnS:Mn 2+ shows a<br />

weak blue emission (430 nm) and an orange emission (600 nm) un<strong>de</strong>r 335 nm<br />

excitation. The blue emission can be assigned to a <strong>de</strong>fect-related emission of<br />

the ZnS host-lattice whereas the orange emission can be attributed to the<br />

4 T1- 6 A1 transition of the Mn 2+ ion.<br />

The sample without Mn 2+ shows only the ZnS-related blue emission.<br />

As soon as Mn 2+ is incorporated in the ZnS nanoparticles, the intensity of<br />

the blue emission <strong>de</strong>creases and the Mn 2+ emission comes up, since the<br />

energy transfer between ZnS host and Mn 2+ impurity is very efficient. With an<br />

increasing Mn 2+ concentration, the characteristic 600 nm emission becomes<br />

stronger.<br />

Figure 3. Emission spectra of ZnS:Mn 2+<br />

pow<strong>de</strong>rs obtained from acetate mixtures<br />

with various Mn 2+ concentration.<br />

26<br />

Figure 4. Relative intensity of the orange<br />

and blue bands versus Mn concentration<br />

(blue band is 5 times multiplied)<br />

In figure 4, the luminescence intensity of the orange and blue bands<br />

is plotted as a function of the Mn/(Zn+Mn) ratio from acetate solution. The<br />

orange band intensity increases with Mn 2+ concentration, in parallel with<br />

the increase of the emission centres numbers. At higher Mn-amounts, the<br />

luminescence intensity starts to <strong>de</strong>crease due to the mutual interaction<br />

between the doping (activator) ions (concentration quenching). The maximum<br />

intensity is reached at about 11% Mn 2+ and corresponds to the optimum<br />

ratio between the number of the emission centres and the quenching ones.<br />

The blue band intensity <strong>de</strong>creases continuously with increasing Mn 2+ amount,<br />

due to the <strong>de</strong>crease of the numbers of self activated centres related with<br />

the lattice <strong>de</strong>fects of the zinc sulphi<strong>de</strong>.<br />

Usually the PL properties of ZnS pow<strong>de</strong>rs are connected with a high<br />

temperature firing stage. In this case, the nanostructure state of ZnS pow<strong>de</strong>rs<br />

<strong>de</strong>termines the unexpected intense luminescence.

PREPARATION AND CHARACTERIZATION OF MANGANESE DOPED ZINC SULPHIDE …<br />

The morphology and particle dimensions were put in evi<strong>de</strong>nce by<br />

scanning (SEM) and transmission (TEM) electron microscopy investigations.<br />

The SEM image of CAI21 sample shows that ZnS:Mn 2+ pow<strong>de</strong>r consists of<br />

1-3 µm aggregates of tightly packed particles with sizes un<strong>de</strong>r 20 nm (Fig. 5).<br />

The TEM image of the same sample illustrates that in fact, the ZnS:Mn 2+<br />

pow<strong>de</strong>r consists from very small particles (quantum dots) with diameters less<br />

than 3 nm. Due to the high surface area, these nanoparticles show a strong<br />

ten<strong>de</strong>ncy toward agglomeration to much larger particles.<br />

Figure 5. SEM image of ZnS:Mn 2+<br />

sample (inset scale bar = 1 μm)<br />

CONCLUSIONS<br />

Figure 6. TEM image of ZnS:Mn 2+<br />

(scale bar=50 nm)<br />

Manganese doped ZnS nanoparticles were obtained by precipitation,<br />

using the sequential reagent addition technique (SeqAdd). In or<strong>de</strong>r to<br />

control the particle morphology and size, methacrylic acid was used as particle<br />

regulating agent. The influence of Mn concentration on the luminescence<br />

properties of ZnS:Mn 2+ nanocrystals was investigated. Photoluminescence<br />

measurements show that the as obtained ZnS:Mn nanopow<strong>de</strong>rs exhibit a<br />

strong orange emission centred at 600 nm that is related with the Mn emission<br />

centres. The maximum intensity is reached at about 11% Mn 2+ in the Zn-Mn<br />

acetate mixture and corresponds to the optimum ratio between the number<br />

of the emission centres and the quenching ones. The strong PL of the unannealed<br />

ZnS:Mn 2+ pow<strong>de</strong>r could be associated with the particle nanodimension.<br />

Although ZnS:Mn 2+ pow<strong>de</strong>rs are formed from nano-sized crystallites<br />

(about 3 nm), they are tightly packed into larger and irregular shaped particles.<br />

The large surface area explains the high absorption capacity of the ZnS<br />

pow<strong>de</strong>r, as illustrated by TGA and FTIR investigations.<br />

Supplementary work has to be done in or<strong>de</strong>r to improve the ZnS:Mn 2+<br />

pow<strong>de</strong>r dispersability.<br />

27

A.-I. CADIŞ, A.R. TOMŞA, E. BICA, L. BARBU-TUDORAN, L. SILAGHI-DUMITRESCU, E.-J. POPOVICI<br />

EXPERIMENTAL SECTION<br />

ZnS pow<strong>de</strong>rs were prepared by precipitation, using SeqAdd technique,<br />

from Zn-Mn acetate and sodium sulphi<strong>de</strong> in aqueous medium, at low<br />

temperatures (5°C). For this purpose, Zn-Mn acetate mixture containing<br />

5.6, 11.0, 16.4, 21.8 and 25.0 mol Mn/100 mol (Zn+Mn) was prepared from<br />

1M Zn(CH3COO)2 and 1M Mn(CH3COO)2 solutions and it was diluted with<br />

<strong>de</strong>ionised water containing α-methacrylic acid (MA). The aqueous solution<br />

of Na2S was ad<strong>de</strong>d to the above mixture solution and vigorously stirred for<br />

30 min. The resulting pow<strong>de</strong>r was washed and centrifuged, and finally dried<br />

at 80°C un<strong>de</strong>r vacuum. The wash process was performed with <strong>de</strong>ionised<br />

water and isopropyl alcohol. As a comparison, pure ZnS nanoparticles were<br />

also prepared using the above method.<br />

A METTLER-TOLEDO TGA/SDTA851 thermogravimeter was used for<br />

thermal and differential thermal gravimetry (TGA-DTG). The measurements<br />

were performed in alumina crucibles, in nitrogen flow (20 mL/min), with a<br />

heating rate of 5°C/min. Infrared absorption spectra (FTIR) of the samples<br />

prepared in KBr pellets were registered on a NICOLET 6700 FT-IR Spectrometer.<br />

Photoluminescence (PL) spectra were registered with JASCO FP-6500 Spectrofluorimeter<br />

Wavel equiped with photomultiplier PMT R928 (Farbglasfilter WG<br />

320-ReichmannFeinoptik) and were normalized to the maximum intensity of<br />

the best sample (CAI73). The scanning electron microscopy (SEM) images<br />

were obtained with a JEOL–JSM 5510LV electron microscope using Au-coated<br />

pow<strong>de</strong>rs. The accelerating voltage was 20 kV. The transmission electron<br />

microscopy (TEM) was performed with JEM JEOL 1010 microscope. The<br />

accelerating voltage was 20 kV.<br />

ACKNOWLEDGMENTS<br />

Financial support for this study was provi<strong>de</strong>d by the Romanian Ministry<br />

of Education, Research and Innovation (Project ID-2488).<br />

28<br />

REFERENCES<br />

1. A. Henglein, Berichte <strong>de</strong>r Bunsengesellschaft für Physikalische Chemie, 1982,<br />

86, 301.<br />

2. H. Gleiter, Progress in Materials Science, 1989, 33, 223.<br />

3. L. F. Chen, Y. H. Shang, J. Xu, H. L. Liu, Y. Hu, Journal of Dispersion Science<br />

and Technology, 2006, 27, 839.

PREPARATION AND CHARACTERIZATION OF MANGANESE DOPED ZINC SULPHIDE …<br />

4. J. Wen, G. L. Wilkes, Chemistry of Materials, 1996, 8, 1667.<br />

5. M. Miyake, T. Torimoto, M. Nishizawa, T. Sakata, H. Mori, H. Yoneyama, Langmuir,<br />

1999, 15, 2714.<br />

6. S. K. Mandal, S. Chaudhuri, A. K. Pal, Thin Solid Films, 1992, 350, 209.<br />

7. A. R. Tomsa, E. J. Popovici, A. I. Cadis, M. Stefan, L. Barbu-Tudoran, S. Astilean,<br />

Journal of Optoelectronics and Advanced Materials, 2008, 10, 2342.<br />

8. R. Thielsch, T. Bohme, H. Bottcher, Physica Status Solidi A, 1996, 155, 157.<br />

9. B. Bhattacharjee, D. Ganguli, S. Chaudhuri, A. K. Pal, Thin Solid Films, 2002,<br />

422, 98.<br />

10. P. Balaz, E. Boldizarova, E. Godocıkova, J. Briancin, Materials Letters, 2003, 57,<br />

1585.<br />

11. J. C. Sanchez-Lopez, A. Fernan<strong>de</strong>z, Thin Solid Films, 1998, 317, 497.<br />

12. J. F. Suyver, S. F. Wuister, J. J. Kelly, A. Meijerink, Nano Letters, 2001, 8, 429.<br />

13. W. B. Sang, Y. B. Qian, J. H. Min, M. D. Li, L. L. Wang, W. M. Shi, Y. F. Liu,<br />

Solid State Communications, 2002, 121, 475.<br />

14. Y. Jiang, Y. J. Zhu, Chemistry Letters, 2004, 33, 1390.<br />

15. H. J. Bai, Z. M. Zhang, J. Gong, Biotechnology Letters, 2006, 28, 1135.<br />

16. N. B. Colthup, L. H. Daly, S. E. Wiberley, “Introduction to Infrared and Raman<br />

Spectroscopy”, Aca<strong>de</strong>mic Press, New York, 1964.<br />

29

STUDIA UNIVERSITATIS BABEŞ-BOLYAI, CHEMIA, LIV, 3, 2009<br />

ELECTRICAL CHARACTERISTICS OF A BIOBATTERY<br />

WITH STAPHYLOCOCCUS AUREUS<br />

COSMIN CĂŢĂNAŞ a , MIHAI MOGOŞ a , DANIEL HORVAT a , JAKAB ENDRE b ,<br />

ELEONORA MARIA RUS a , IULIU OVIDIU MARIAN a<br />

ABSTRACT. A homema<strong>de</strong> biobattery was studied from electrical point of view.<br />

The open circuit voltage for a 0.2 mA short circuit current was of 0.6 V. The<br />

maximum power for an internal resistance of 1.1 kΩ and a concentration of<br />

10 9 cells/cm 3 of Staphylococcus aureus was of 17.57 μW.<br />

Keywords: biobattery, electrical power, bacteria, Staphylococcus aureus.<br />

INTRODUCTION<br />

In the last years, microbial fuel cells (MFCs) have received a great <strong>de</strong>al<br />

of attention as a promising solution for renewable energy generation and waste<br />

disposal [1-6]. A MFC converts energy, available in a bio-convertible substrate,<br />

directly into electricity through the catalytic activities of microorganisms.<br />

It can be said that the MFCs are a hybrid of biological and electrochemical<br />

reactors. By this dualistic nature, MFCs offer the advantage of utilizing<br />

a wi<strong>de</strong> range of organic compounds as fuel, and exploit the value of electrochemical<br />

cells by direct generation of electricity [7].<br />

In a MFC, electricity is being generated in a direct way from biowastes<br />

and organic matter. This implies that the overall conversion efficiencies that can<br />

be reached are potentially higher for MFCs compared to other biofuel processes.<br />

Parameters influencing the overpotentials at the ano<strong>de</strong> are the<br />

electro<strong>de</strong> surface, the electrochemical characteristics of the electro<strong>de</strong>, the<br />

electro<strong>de</strong> potential, and the kinetics together with the mechanism of the<br />

electron transfer and the current of the MFC.<br />

Mediators are important in MFC cells that use microorganisms such<br />

as Escherichia coli, Pseudomonas, Proteus, and Bacillus species that are<br />

unable to effectively transfer electrons <strong>de</strong>rived from central metabolism to the<br />

a Babeş-Bolyai University, Faculty of Chemistry and Chemical Engineering, Romania, Cluj-<br />

Napoca, Arany Ianos, 11 iomar@chem.ubbcluj.ro<br />

b Babeş-Bolyai University, Center for Molecular Biology, Romania, Cluj-Napoca, Treboniu<br />

Laurian, 42

32<br />

C. CĂŢĂNAŞ, M. MOGOŞ, D. HORVAT, E. JAKAB, E. M. RUS, I. O. MARIAN<br />

outsi<strong>de</strong> of the cell. Common electron shuttles inclu<strong>de</strong> thionine, benzylviologen,<br />

2,6-dichlorophenolindophenol, 2-hydroxy-1,4-naphtho-quinone and various<br />

phenazines, phenothiazines, phenoxoazines, iron chelates and neutral red [8].<br />

These electron shuttles are typically capable to cross the cell membranes,<br />

accepting electrons from one or more electron carriers within the cell, exiting<br />

the cell in the reduced form and then transferring electrons onto the electro<strong>de</strong><br />

surface. The critical issue with mediated electron transfer is the diffusion of<br />

the shuttle out of the biofilm or the bacterial environment [9].<br />

There is a report on the bacteria, Rhodoferax ferrireducens that can<br />

be used in microbial fuel cells effectively without a mediator [10].<br />

Oxygen is generally used as the electron acceptor for the cathodic<br />

reaction in MFCs. Graphite is a commonly used electro<strong>de</strong> material. To improve<br />

catalytic activity, graphite can be modified with platinum [11].<br />

Various metals (copper, gold, palladium/cobalt, molyb<strong>de</strong>num, tungsten,<br />

and manganese) and their complexes have been investigated as replacements<br />

for expensive platinum in the catho<strong>de</strong> [11-13].<br />

Because the power output of MFCs is low relative to other types of fuel<br />

cells, reducing their cost is essential, if power generation using this technology<br />

is to be an economical method of energy production. Further research is<br />

required to enhance the power production.<br />

In this study, we investigate the performance of a biobattery with<br />

Staphylococcus aureus bacteria without mediator in the original arrangement<br />

of electro<strong>de</strong> materials at ano<strong>de</strong> compartment because the biobatteries are<br />

less investigated at this moment.<br />

RESULTS AND DISCUSSION<br />

The purpose of the experiments was to measure the open circuit<br />

voltage, the short circuit current and to plot the power curve of the biobattery.<br />

The bacteria used in the experiment were Staphylococcus aureus and the<br />

substrate was the sodium acetate.<br />

FeCl3 was used as a catho<strong>de</strong> mediator in or<strong>de</strong>r to improve oxygen<br />

reduction kinetics [14-15] and acetate was used as substrate in the anodic<br />

compartment. The purpose of the experiment was to measure the voltage<br />

between the two compartments at 2 different concentrations of acetate in<br />

the absence and presence of the bacteria. The activation of the biobattery<br />

has been achieved by adding the bacterial solution. After a few seconds it<br />

was observed the bubbling process on the ano<strong>de</strong> rods electro<strong>de</strong> material<br />

due to the carbon dioxi<strong>de</strong> gas resulted from the bacterial activity.<br />

The pH of first solution was 8.6 and for the second solution 8.9.

ELECTRICAL CHARACTERISTICS OF A BIOBATTERY WITH STAPHYLOCOCCUS AUREUS<br />

Figure 1. Biobattery representation<br />

In the first experiment by monitoring the cell voltage for 5 hours, a drift<br />

of OCV (open circuit voltage) appears from 0.46V to 0.42 V before activation.<br />

A maximum peak of 0.6 V was measured after biobattery activation. The short<br />

circuit current was of 0.2 mA. (Figure.2a).<br />

a b<br />

Figure 2. Voltage-time <strong>de</strong>pen<strong>de</strong>ncy.<br />

a) for 0.05M sodium acetate solution b) for 0.1M sodium acetate solution<br />

In the second experiment before activation the same drift appear<br />

(about 40mV) and after activation we measured a maximum cell voltage of<br />

0.3 V and the short circuit current of 0.2mA (Figure 2b). In both cases the<br />

open circuit voltage remains at the constant values of 0.56V respectively<br />

0.26 V for one month. Current-time curve and power curve, was recor<strong>de</strong>d<br />

for the biobattery with increased OCV.<br />

33

34<br />

C. CĂŢĂNAŞ, M. MOGOŞ, D. HORVAT, E. JAKAB, E. M. RUS, I. O. MARIAN<br />

Figure 3. Short circuit current-time <strong>de</strong>pen<strong>de</strong>ncy<br />

0.05M sodium acetate solution<br />

Initially, after the biobattery activation, a peak current of about 200 µA<br />

was registered. After 20 minutes, the limit current of about 20 µA was reached<br />

in agreement with the last point of the power curve (Figure 4).<br />

Figure 4. Power curve 0.05M sodium acetate solution

ELECTRICAL CHARACTERISTICS OF A BIOBATTERY WITH STAPHYLOCOCCUS AUREUS<br />

As we reduce the external resistance, a <strong>de</strong>crease of the voltage<br />

was recor<strong>de</strong>d. In this way, we looked for having the smallest possible drop<br />

in voltage as the current is increased in or<strong>de</strong>r to attain the maximum power<br />

production over the investigated range of interest.<br />

The internal resistance of the battery and the maximum power<br />

generated were calculated by using the Mathworks MATLAB® environment<br />

for processing the experimental data. Spline functions have been used to<br />

approximate the power curve. (Figure 4).<br />

All of the equipment used was sterilized with hydrogen peroxi<strong>de</strong><br />

after the experiments.<br />

CONCLUSIONS<br />

The maximum power of the biobattery was of 17.57 µW, achieved at the<br />

internal resistance of 1.1 kΩ and for the external resistance of about 15 kΩ<br />

the minimum power reached was 5.45 µW, in the case of 0.05M substrate<br />

concentration in ano<strong>de</strong> compartment.<br />

The value of the OCV remained at the constant value of about 0.56 V<br />

for a month. The difference which appears in OCV in both experiments can be<br />

explained by <strong>de</strong>creasing of the bacterial activity whit pH increase.<br />

The biobatteries represent a viable method of generating electricity<br />

from chemical energy. Further research must be done with the purpose of<br />

reducing the dimensions of the biobattery for possible applications in medicine<br />

and other fields.<br />

EXPERIMENTAL SECTION<br />

An electrochemical cell has been built with two chambers separated by<br />

a Nafion proton exchange membrane (Figure 1). Nine graphite rod electro<strong>de</strong>s<br />

of 6 mm in diameter and10 cm in length have been used for each chamber.<br />

For the ano<strong>de</strong> compartment a 300 ml sodium acetate solution 0.05 M and<br />

0.1 M respectively, has been combined with 2 ml of Staphylococcus aureus<br />

(10<br />

35<br />

9 cell/ml concentration). For the catho<strong>de</strong> compartment, 300 ml of 1 M FeCl3<br />

solution was used.<br />

The circuits which contain a biobattery and multimeters were connected<br />

to a computer with continuous data acquisition software.<br />

The used bacteria were Staphylococcus aureus. The bacteria posed<br />

no threat to the working environment because they were non sporogenous.<br />

Bacterial strains. Both used bacterial strains, the UCLA 8076 (University<br />

of California, Los Angeles, USA) [16] and the 1190R (Semmelweis University,<br />

Budapest, Hungary) [17], were heterogeneous MRSA (methicillin-resistant<br />

Staphylococcus aureus)strains. These strains are preserved in glycerol (25%<br />

final concentration) at -80°C and prepared as follows: 5ml of overnight bacteria<br />

culture at 37°C in LB broth (Gibco BRL, Life Technologies, Paisley, Scotland)

C. CĂŢĂNAŞ, M. MOGOŞ, D. HORVAT, E. JAKAB, E. M. RUS, I. O. MARIAN<br />

were centrifuged in 15ml centrifuge tubes in a Sigma 1-18K centrifuge (Sigma<br />

Laborzentrifugen, Ostero<strong>de</strong> am Harz, Germany –5,500 rpm, 10 min., room<br />

temperature) and the pellet was resuspen<strong>de</strong>d in 500μl sterile 50% glycerol.<br />

The thawed bacteria were cultured overnight in 5ml of Mueller Hinton<br />

broth (Fluka, Buchs, Switzerland) into a Certomat BS-T incubation shaker<br />

(Sartorius Stedim Biotech, Aubagne, France) at 37°C, 150 rpm until the<br />

culture reached an OD600 of 0.8-1.0 (Spekol UV VIS 3.02, Analytic Jena, Jena,<br />

Germany). A loop of bacterial suspension was passed on Mueller Hinton agar<br />

(Fluka, Buchs, Switzerland) to maintain the culture for further analysis. The<br />

bacteria were cultured also on blood agar plates (Fluka, Buchs, Switzerland)<br />

and confirmed using colony morphology method.<br />

REFERENCES<br />

1. K.J. Chae, M. Choi, F.F. Ajayi, W. Park, I.S. Chang and I.S. Kim, Energy & Fuels,<br />

2008, 22, 169.<br />

2. B.H. Kim, I.S. Chang, G.M. Gadd, Appl. Microbiol. Biotechnol., 2007, 76, 485.<br />

3. B.E. Logan, Water Science & Technology, 2005, 52, 31.<br />

4. B.E. Rittmann et all., Environ. Sci. Tech., 2006, 15, 1097.<br />

5. D.R. Lovley, Microbiology, 2006, 4, 497.<br />

6. A.K. Shukla, P. Suresh, S. Berchmans, A. Rajendran, Current Science, 2004, 87,<br />

455.<br />

7. A.K. Marcus, C.I. Torres, B.E. Rittmann, Biotechnology and Bioengineering,<br />

2007, 98, 1171.<br />

8. K. Rabaey, W. Verstraete, TRENDS in Biotechnology, 2005, 23, 291.<br />

9. S.E. Chil<strong>de</strong>rs, S. Ciufo, D.R. Lovley, Nature, 2002, 416, 767.<br />

10. A.K. Shukla, P. Suresh, S. Berchmans and A. Rajendran, Current Science, 2004,<br />

87, 455.<br />

11. T.H. Pham, J.K. Jang, I.S. Chang, and B.H. Kim, J. Microbiol. Biotechnol., 2004,<br />

14, 324.<br />

12. K.H. Kang, J.K. Jang, T.H. Pham, H.I. Moon, S.B. Chang, H. Kim, Biotechnol. Lett.,<br />

2003, 25, 1357.<br />

13. I.S. Chang, J.K. Jang, G.C. Gil, M. Kim, H.J. Kim, B.W. Cho, Biosens. Bioelectron.,<br />

2004, 19, 607.<br />

14. S. Cheng, H. Liu, B.E. Logan, Environ. Sci.Technol., 2006, 40, 364.<br />

15. B.H. Kim, H.J. Kim, M.S. Hyun, D.H. Park, J. Microbiol.Biotechnol., 1999, 9, 127.<br />

16. J.M. Swenson, F.C. Tenover, J. Clinical Microbiology, Cefoxitin Disk Study Group,<br />

2005, 43(8), 3818.<br />