ReCorr®QCQ Benefits

In today’s competitive and technologically demanding world, the power of innovation can hardly be underestimated. The advantages of the innovative QCQ device can serve as leverage to gain sustainable benefits from DIFFERENTIATING PRODUCTS AND SERVICES ON THE MARKET and AVOIDING PRODUCTION LOSSES AND HIGH MAINTENANCE COSTS.

- unique to the market

- simple and fast

- non-destructive

- portable

- applicable in the field and in the laboratory

- quantitative readout

- high-resolution

- integrated a.c. interference management

- single frequency or spectrum analysis

- substrate contact not mandatory

- uses self-adhering electrodes

- works on surfaces of any orientation

- adjustable electrode size

- no Faraday cage necessary

Device Architecture

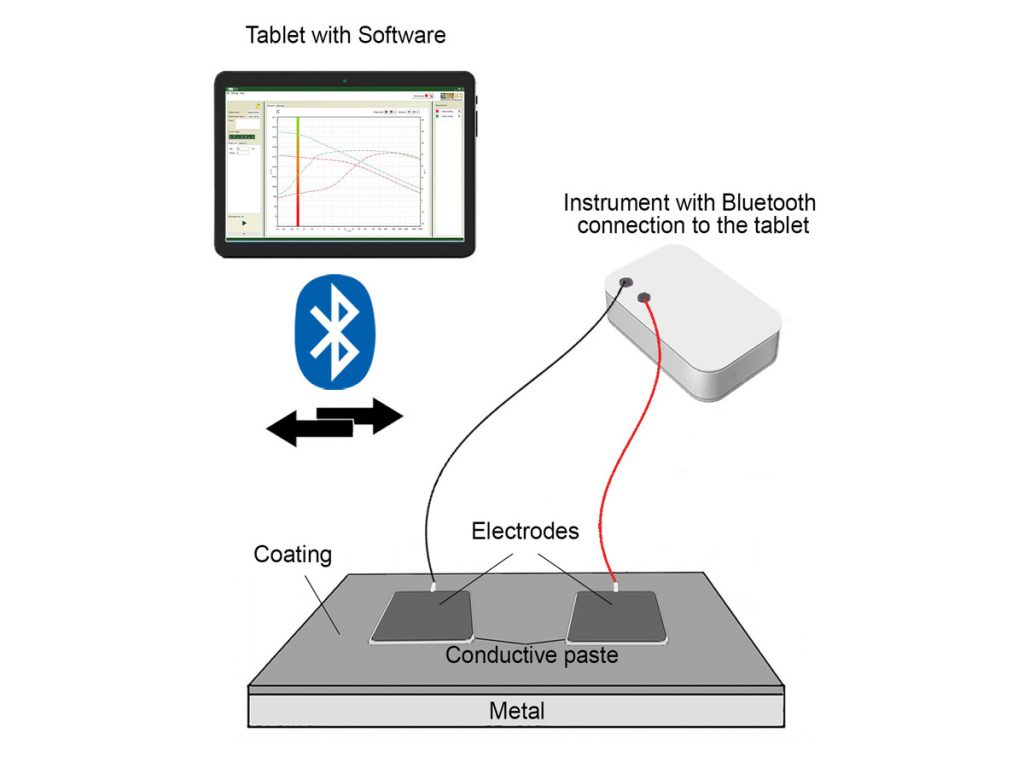

The device consists of a pair of flexible, conductive polymer sensor electrodes sticking to a coated surface with the aid of a low-resistivity paste. The electrodes are connected to the impedance spectroscopy instrument run from the Android tablet.

Any coated metallic object is suitable for ReCorr® QCQ measurements. In a custom configuration, the sample should accommodate a single sensor electrode or a pair of sensor electrodes with dimensions 4 cm × 6 cm surrounded by at least 1 cm of the coated surface.

For small or irregularly shaped samples and for continuous monitoring, customized electrode design is used.

QA/QC

The fast and easy application allows rating of the coatings with high confidence by performing a large number of measurements on duplicate samples or large coating areas, as well as performing a statistical analysis and taking into account the measurement uncertainty.

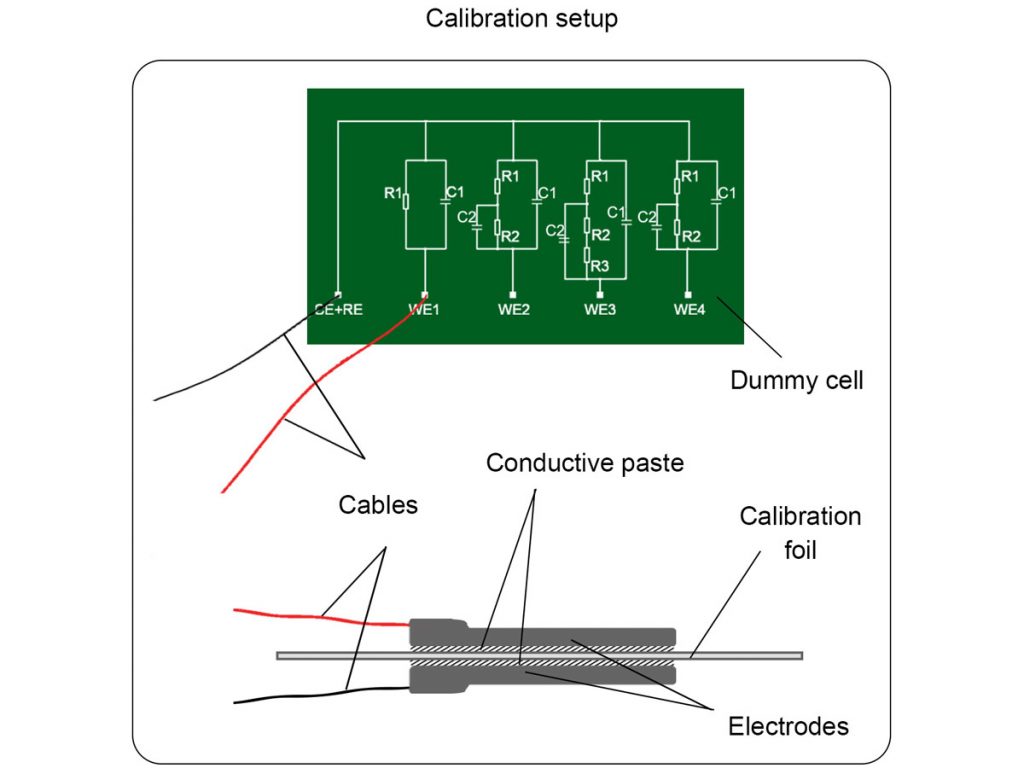

The measurement capability is verified according to ISO 13776-3 by dummy cell circuits with capacitance and resistance values of the order of magnitude expected for the actual coated specimens. Calibration foils of the thickness comparable to that of the coating can also be used.

Very accurate and precise measurements (≥ 97%) can be obtained outside the Faraday cage using the built-in software function for AC interference management.