200824 Crate dropped during lowering

On a ship at anchor, a crate containing machinery spares, reeved with two webbing slings, was being lowered into the engine room through the engine room hatch using the ship’s stores crane. During the lowering process, a corner of the base of the crate caught on a section of ducting immediately below the hatch coaming, became unbalanced and tipped through the slings, falling to the deck below. The impact destroyed the crate; however, there were no injuries or damage other than that the spares were rendered unuseable.

Root cause/contributory factors

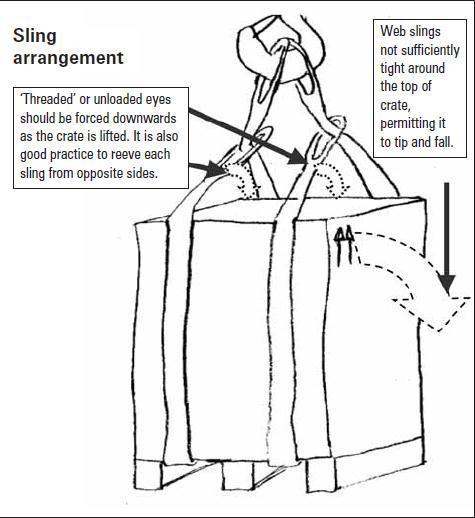

Failure to sling the crate properly; webbing slings not tight around the top of the crate;

Ship rolling slightly at anchorage, causing the crate to swing during passage through hatch;

Failure to conduct / review formal risk assessment prior to the lifting operation;

It is thought that the spare part was inadequately secured inside the crate and as the crate tilted, the internal shift of weight assisted the ‘tipping’ motion;

The crate’s height was greater than the other two dimensions, which made it more prone to tipping;

The crate had no fitting to prevent the slings from slipping off in case the load became unbalanced;

‘Routine task’ complacency and inadequate understanding of risk assessment among the ratings.

Corrective actions

The company issued notices to masters and safety bulletins on risk assessment, work planning and safe lifting techniques.

Crane operator familiarisation training was conducted on board and will be supplemented by further computer based or practical training in crane operations and rigging / slinging.

Permit to work system presently applying only to lifts within hazardous areas to be extended to include all lifting tasks.

Investigate and solicit vessel proposals for a steel cage / box to be used for lifting operations into engine room.

Lessons learnt

Expensive and relatively fragile components should be given a higher level of planning and supervision.

Although a task review was conducted during the initial work planning, it was not documented and should have been followed up with risk assessment and a tool box meeting.

There was a failure to assess the risks adequately, specifically vessel motion and the possibility of the crate contents shifting.

FEEDBACK Aug 2008

There are various comments on this in the entry but I would take this opportunity to highlight the following:

The value of the goods contained within the crate can easily be established, but the centre of gravity of the contents is (or was) a mystery. Based on the foregoing statement, the suggested method of proper slinging was incorrect as shown in the diagram.

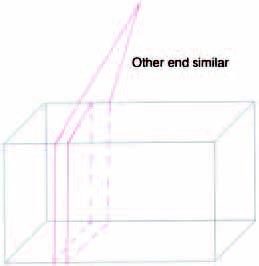

The only positive method of restraining any movement would be to sling it as shown in the diagram below. This method is an age-old traditional method known as a 'body and soul' slinging arrangement.

Editor's note: While this arrangement is definitely superior, in the original report, it was mentioned that the case was unusually tall, which would probably mean that each of the pair of slings required would measure upwards of, say, 15 metres in length. Ideally, an efficient slinging arrangement for awkward packages should be provided by the packer. From the report, it appears either that the slings used were not long enough for this method or that the ship could not produce or improvise a pair of slings of suitable length.

The method suggested by the Editor involves shorter slings like those illustrated in the original report and the 'tightening' is achieved simply by a person holding or tapping down the unloaded eye as the weight is taken by the lifting appliance. This method has been successfully used by stevedores the world over for decades, if not centuries.