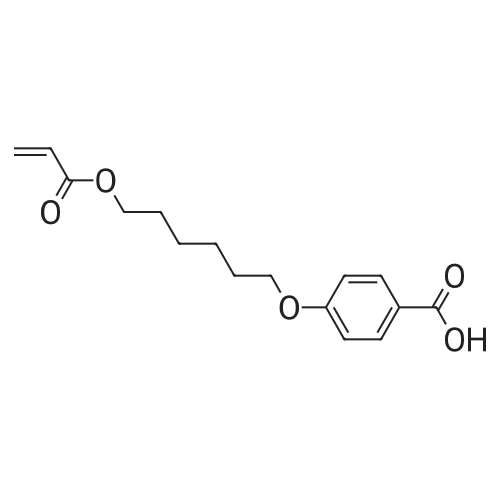

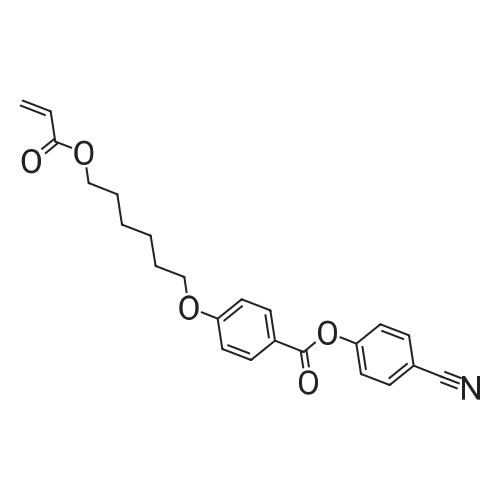

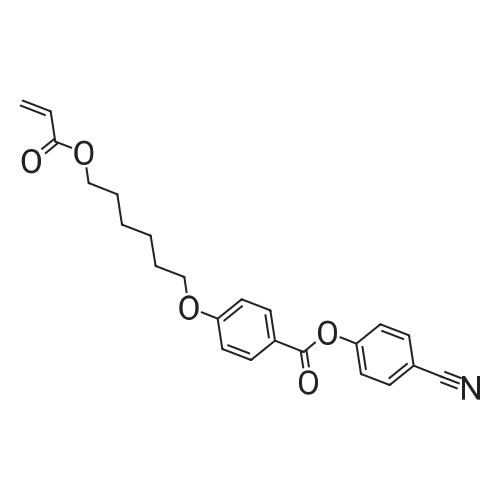

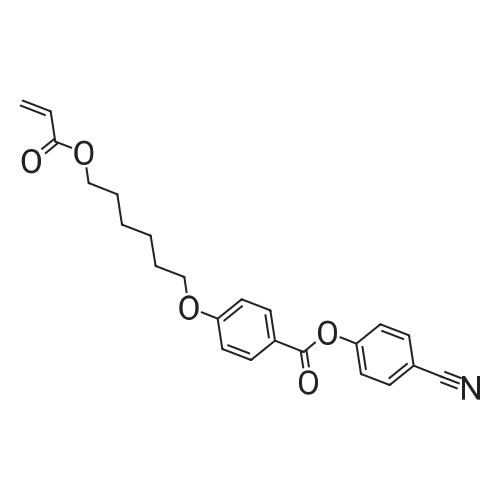

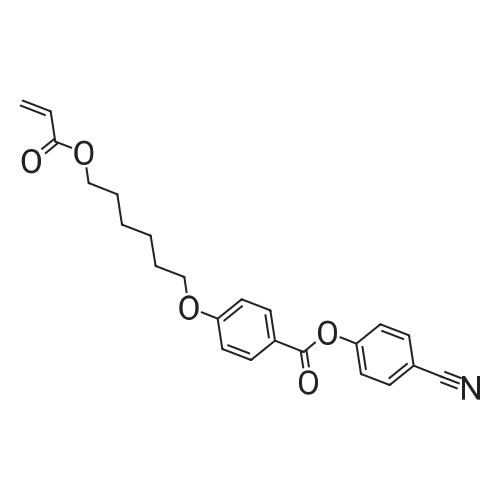

Alternatived Products of [ 83847-14-7 ]

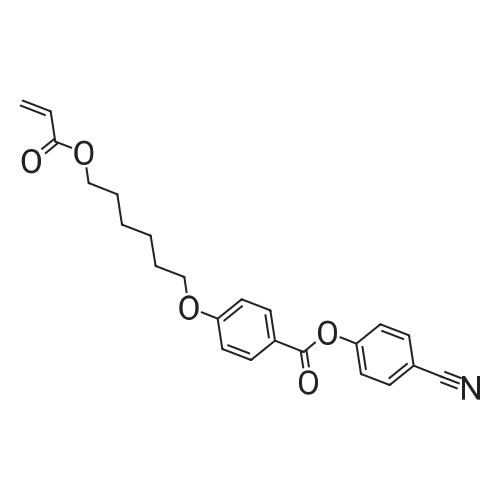

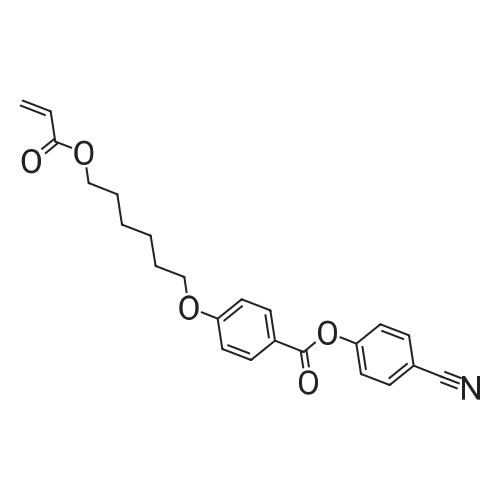

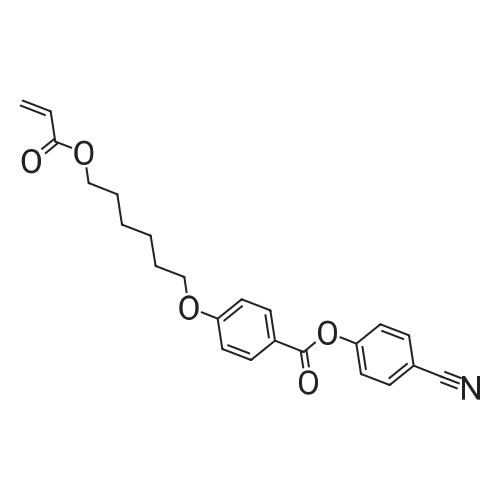

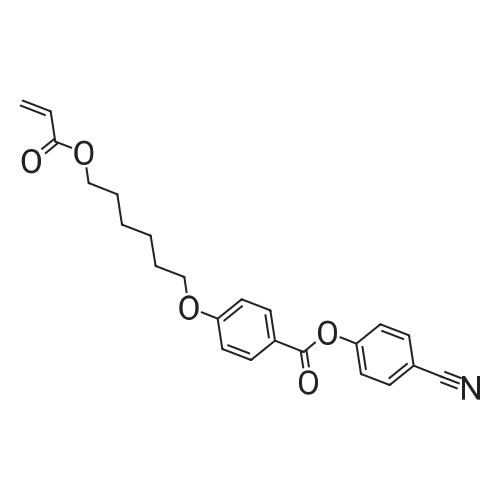

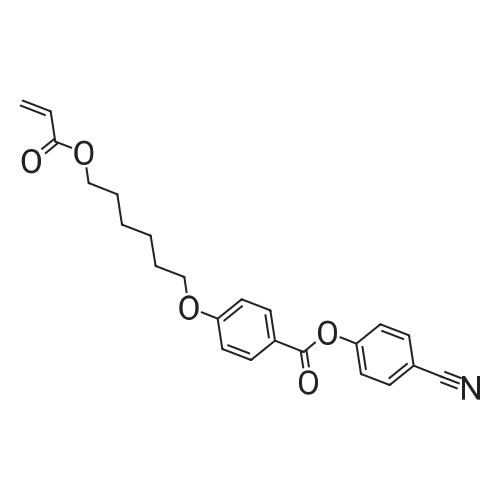

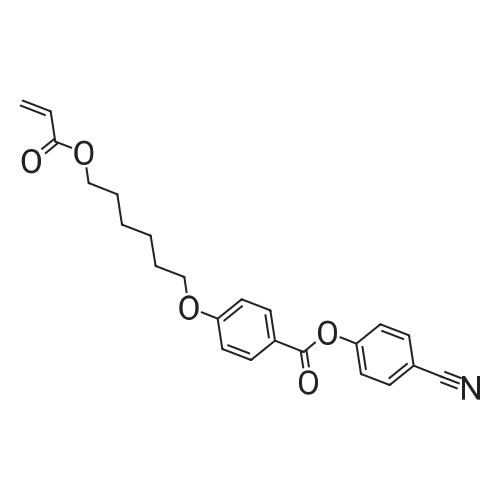

Product Details of [ 83847-14-7 ]

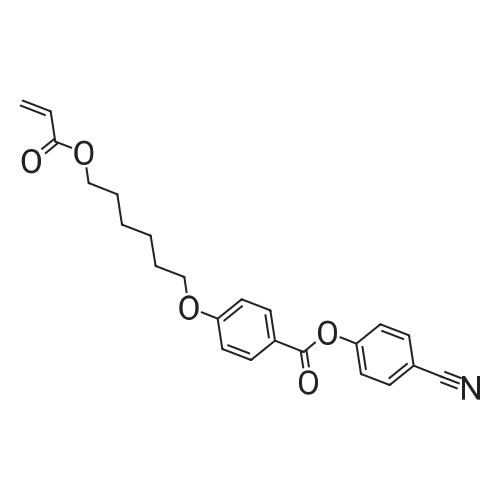

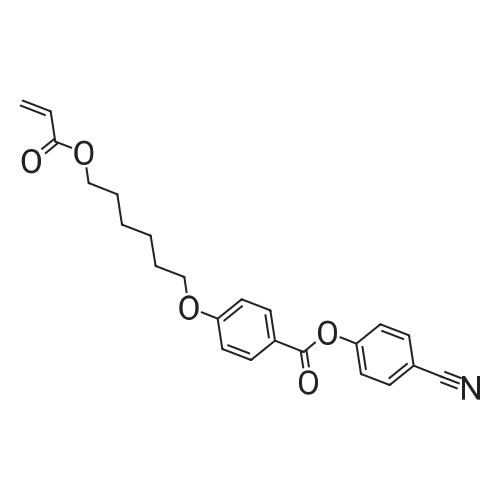

| CAS No. : | 83847-14-7 |

MDL No. : | MFCD23098829 |

| Formula : |

C23H23NO5

|

Boiling Point : |

- |

| Linear Structure Formula : | - |

InChI Key : | LNEDNZUQKOGNLJ-UHFFFAOYSA-N |

| M.W : |

393.43

|

Pubchem ID : | 640210 |

| Synonyms : |

|

Application In Synthesis of [ 83847-14-7 ]

* All experimental methods are cited from the reference, please refer to the original source for details. We do not guarantee the accuracy of the content in the reference.

- Downstream synthetic route of [ 83847-14-7 ]

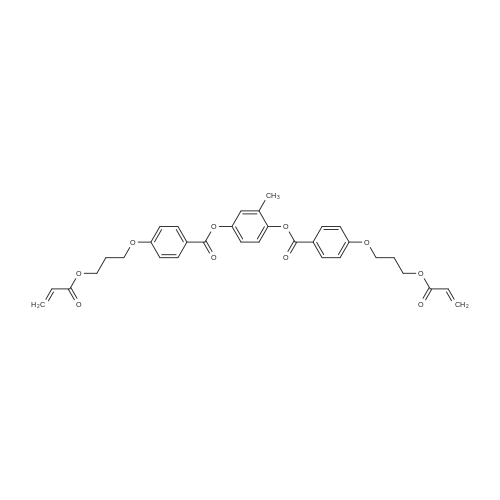

- 1

-

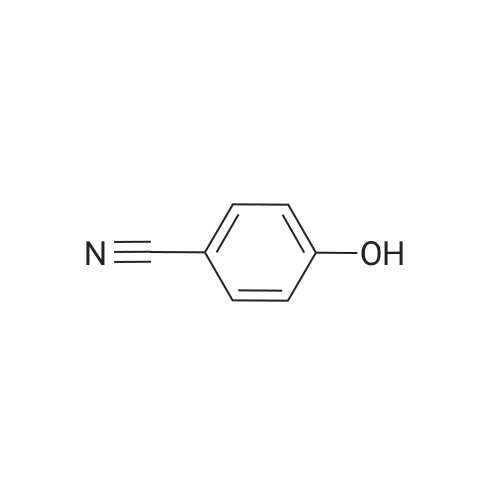

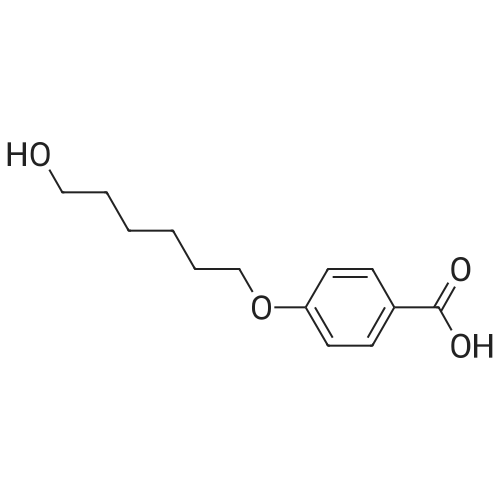

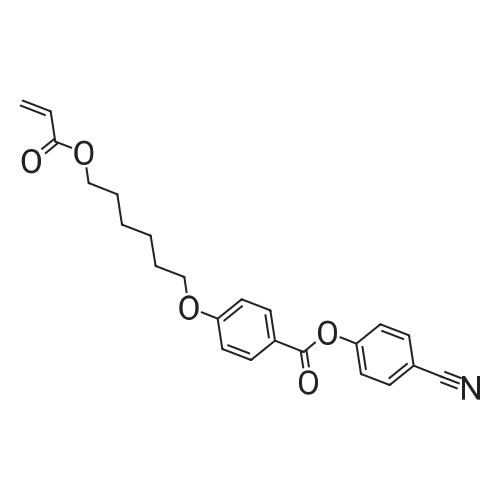

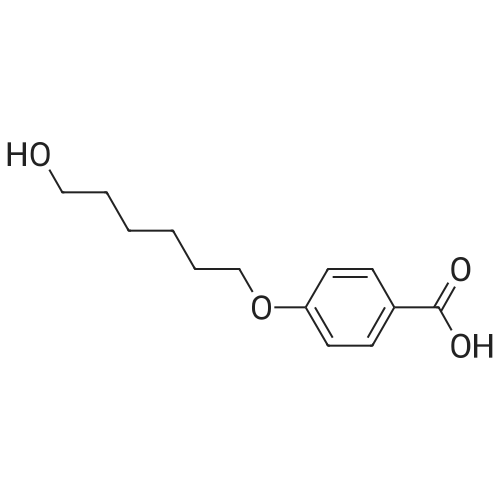

[ 767-00-0 ]

[ 767-00-0 ]

-

[ 83883-26-5 ]

[ 83883-26-5 ]

-

[ 83847-14-7 ]

[ 83847-14-7 ]

- 2

-

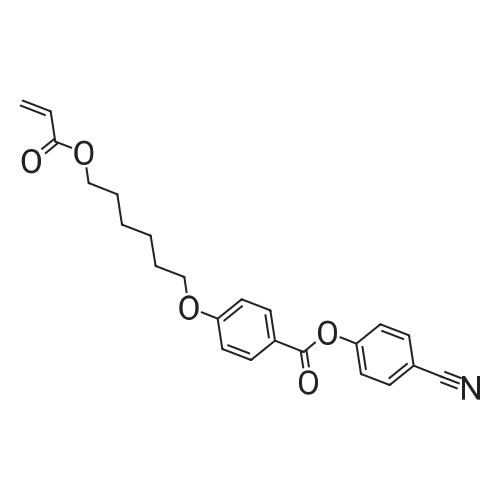

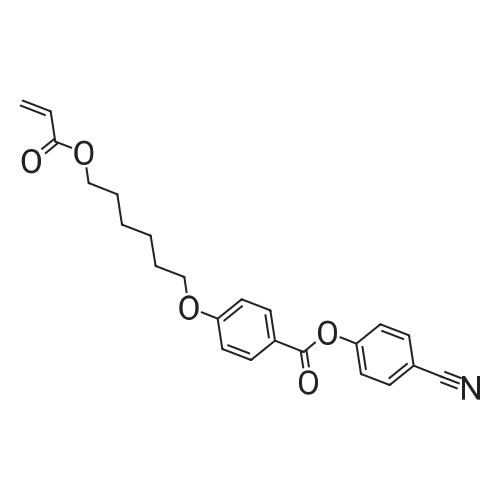

[ 83847-14-7 ]

[ 83847-14-7 ]

-

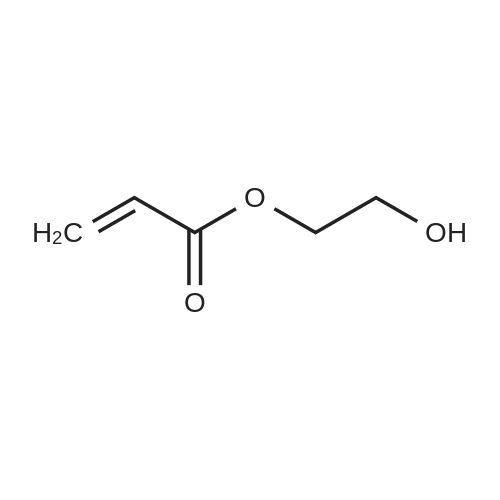

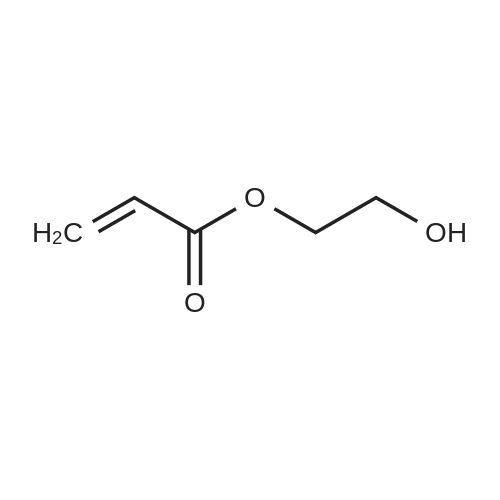

[ 818-61-1 ]

[ 818-61-1 ]

-

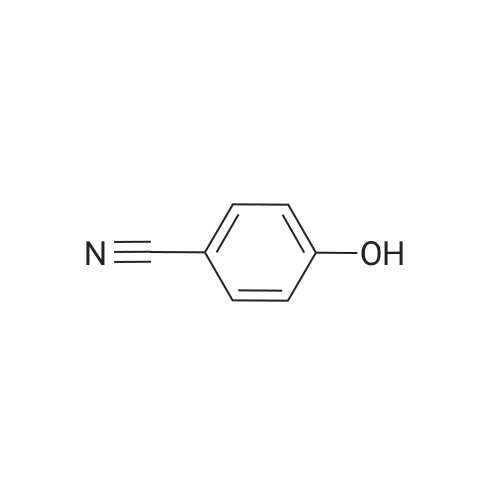

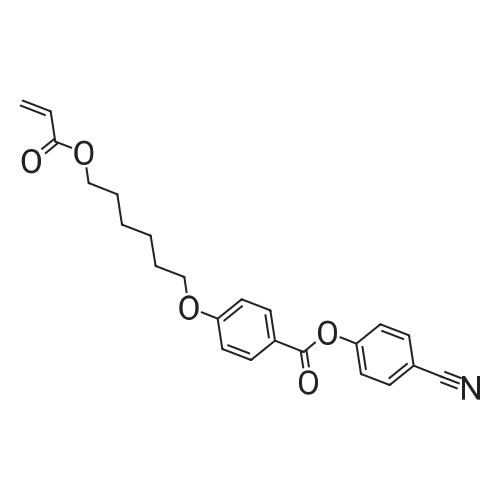

polymer, degree of polymerization 200, polydispersity 2; monomer(s): 2-hydroxyethyl acrylate, 10 percent; 4-(6-acryloyloxy-hexyloxy)-benzoic acid 4-cyano-phenyl ester

[ No CAS ]

| Yield | Reaction Conditions | Operation in experiment |

|

With 2,2'-azobis(isobutyronitrile) at 55℃; |

|

- 3

-

[ 83847-14-7 ]

[ 83847-14-7 ]

-

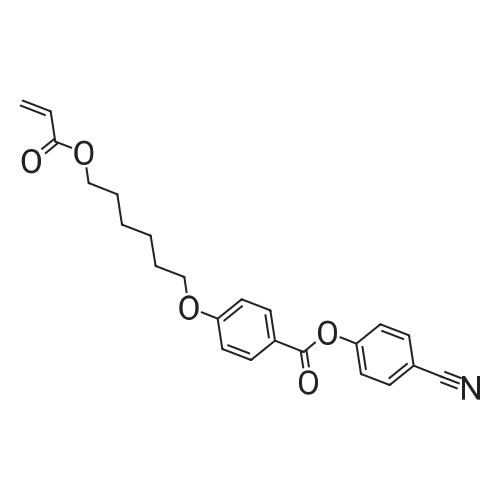

polymer, dispersion polymerization, colloid diameter (standard deviation) = 0.69 (0.05) μm; monomer(s): 4-(6-acryloyloxy-hexyloxy)benzoic acid 4-cyanophenyl ester

[ No CAS ]

| Yield | Reaction Conditions | Operation in experiment |

|

With hydroxypropyl cellulose (Mn = 82020, Mw = 138000 g/mol); dibenzoyl peroxide In ethanol at 75℃; for 24h; |

|

- 4

-

[ 83847-14-7 ]

[ 83847-14-7 ]

-

polymer, dispersion polymerization (in ethanol/2-methoxyethanol 10:1), colloid diameter (standard deviation) = 0.75 (0.05) μm; monomer(s): 4-(6-acryloyloxy-hexyloxy)benzoic acid 4-cyanophenyl ester

[ No CAS ]

| Yield | Reaction Conditions | Operation in experiment |

|

With hydroxypropyl cellulose (Mn = 82020, Mw = 138000 g/mol); dibenzoyl peroxide In ethanol; 2-methoxy-ethanol at 75℃; for 24h; |

|

- 5

-

[ 83847-14-7 ]

[ 83847-14-7 ]

-

polymer, dispersion polymerization (in ethanol/2-methoxyethanol 4:1), colloid diameter (standard deviation) = 0.83 (0.06) μm; monomer(s): 4-(6-acryloyloxy-hexyloxy)benzoic acid 4-cyanophenyl ester

[ No CAS ]

| Yield | Reaction Conditions | Operation in experiment |

|

With hydroxypropyl cellulose (Mn = 82020, Mw = 138000 g/mol); dibenzoyl peroxide In ethanol; 2-methoxy-ethanol at 75℃; for 24h; |

|

- 6

-

[ 83847-14-7 ]

[ 83847-14-7 ]

-

polymer, dispersion polymerization (in ethanol/2-methoxyethanol 2:1), colloid diameter (standard deviation) = 1.01 (0.08) μm; monomer(s): 4-(6-acryloyloxy-hexyloxy)benzoic acid 4-cyanophenyl ester

[ No CAS ]

| Yield | Reaction Conditions | Operation in experiment |

|

With hydroxypropyl cellulose (Mn = 82020, Mw = 138000 g/mol); dibenzoyl peroxide In ethanol; 2-methoxy-ethanol at 75℃; for 24h; |

|

- 7

-

[ 83847-14-7 ]

[ 83847-14-7 ]

-

polymer, dispersion polymerization (in ethanol/2-methoxyethanol 1:1), colloid diameter (standard deviation) = 1.16 (0.07) μm; monomer(s): 4-(6-acryloyloxy-hexyloxy)benzoic acid 4-cyanophenyl ester

[ No CAS ]

| Yield | Reaction Conditions | Operation in experiment |

|

With hydroxypropyl cellulose (Mn = 82020, Mw = 138000 g/mol); dibenzoyl peroxide In ethanol; 2-methoxy-ethanol at 75℃; for 24h; |

|

- 8

-

[ 83847-14-7 ]

[ 83847-14-7 ]

-

polymer, dispersion polymerization (in ethanol/2-methoxyethanol 2:3), colloid diameter (standard deviation) = 1.74 (0.75) μm; monomer(s): 4-(6-acryloyloxy-hexyloxy)benzoic acid 4-cyanophenyl ester

[ No CAS ]

| Yield | Reaction Conditions | Operation in experiment |

|

With hydroxypropyl cellulose (Mn = 82020, Mw = 138000 g/mol); dibenzoyl peroxide In ethanol; 2-methoxy-ethanol at 75℃; for 24h; |

|

- 9

-

[ 83847-14-7 ]

[ 83847-14-7 ]

-

polymer, dispersion polymerization (in ethanol/2-methoxyethanol 1:2), colloid diameter (standard deviation) = 3.65 (2.95) μm; monomer(s): 4-(6-acryloyloxy-hexyloxy)benzoic acid 4-cyanophenyl ester

[ No CAS ]

| Yield | Reaction Conditions | Operation in experiment |

|

With hydroxypropyl cellulose (Mn = 82020, Mw = 138000 g/mol); dibenzoyl peroxide In ethanol; 2-methoxy-ethanol at 75℃; for 24h; |

|

- 10

-

[ 83847-14-7 ]

[ 83847-14-7 ]

-

polymer, dispersion polymerization (in ethanol/2-methoxyethanol 1:5), colloid diameter (standard deviation) = 2.4 (1.1) μm; monomer(s): 4-(6-acryloyloxy-hexyloxy)benzoic acid 4-cyanophenyl ester

[ No CAS ]

| Yield | Reaction Conditions | Operation in experiment |

|

With hydroxypropyl cellulose (Mn = 82020, Mw = 138000 g/mol); dibenzoyl peroxide In ethanol; 2-methoxy-ethanol at 75℃; for 24h; |

|

- 11

-

[ 83847-14-7 ]

[ 83847-14-7 ]

-

polymer, dispersion polymerization, colloid diameter up to 30 μm; monomer(s): 4-(6-acryloyloxy-hexyloxy)benzoic acid 4-cyanophenyl ester

[ No CAS ]

| Yield | Reaction Conditions | Operation in experiment |

|

With hydroxypropyl cellulose (Mn = 82020, Mw = 138000 g/mol); dibenzoyl peroxide In 2-methoxy-ethanol at 75℃; for 24h; |

|

- 12

-

[ 83847-14-7 ]

[ 83847-14-7 ]

-

polymer, seed polymerization, colloid diameter = 1.57 +/- 0.12 μm; monomer(s): 4-(6-acryloyloxy-hexyloxy)benzoic acid 4-cyanophenyl ester

[ No CAS ]

| Yield | Reaction Conditions | Operation in experiment |

|

With hydroxypropyl cellulose; dibenzoyl peroxide In ethanol; 2-methoxy-ethanol at 75℃; for 24h; |

|

- 13

-

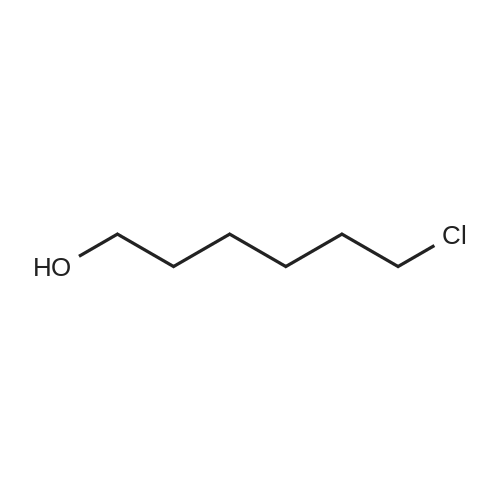

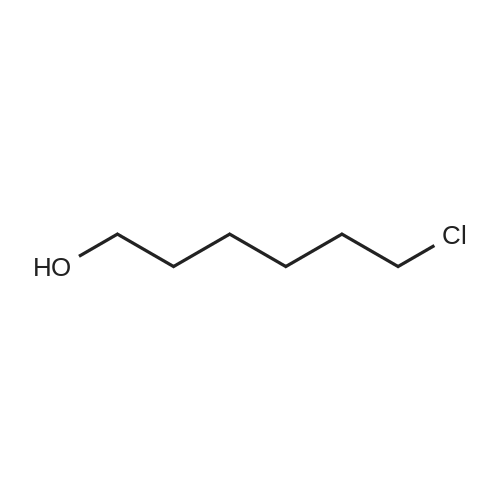

[ 2009-83-8 ]

[ 2009-83-8 ]

-

[ 83847-14-7 ]

[ 83847-14-7 ]

| Yield | Reaction Conditions | Operation in experiment |

|

Multi-step reaction with 3 steps

1: 54 percent / potassium iodide, potassium hydroxide / ethanol; H2O / 20 h / Heating

2: 67 percent / hydroquinone, p-toluenesulphonic acid / benzene / 20 h / Heating

3: 1.) thionyl chloride, 2,6-di-tert-butyl-4-methyl phenol, DMF; 2.) triethylamine / 1.) 25 min; 2.) chloroform, room t., 24 h |

|

- 14

-

[ 83883-25-4 ]

[ 83883-25-4 ]

-

[ 83847-14-7 ]

[ 83847-14-7 ]

| Yield | Reaction Conditions | Operation in experiment |

|

Multi-step reaction with 2 steps

1: 67 percent / hydroquinone, p-toluenesulphonic acid / benzene / 20 h / Heating

2: 1.) thionyl chloride, 2,6-di-tert-butyl-4-methyl phenol, DMF; 2.) triethylamine / 1.) 25 min; 2.) chloroform, room t., 24 h |

|

- 15

-

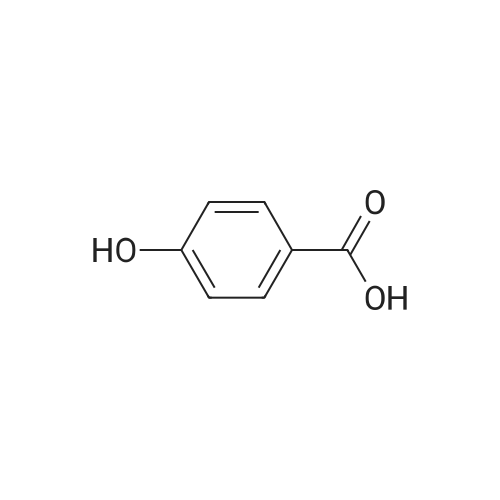

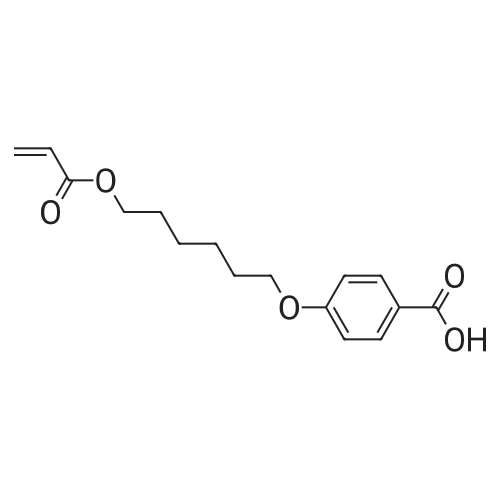

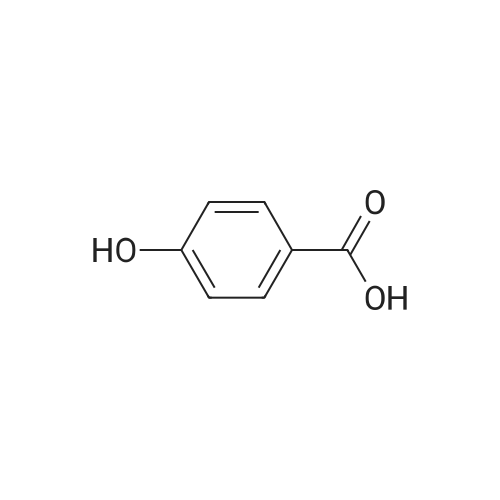

[ 99-96-7 ]

[ 99-96-7 ]

-

[ 83847-14-7 ]

[ 83847-14-7 ]

| Yield | Reaction Conditions | Operation in experiment |

|

Multi-step reaction with 3 steps

1: 54 percent / potassium iodide, potassium hydroxide / ethanol; H2O / 20 h / Heating

2: 67 percent / hydroquinone, p-toluenesulphonic acid / benzene / 20 h / Heating

3: 1.) thionyl chloride, 2,6-di-tert-butyl-4-methyl phenol, DMF; 2.) triethylamine / 1.) 25 min; 2.) chloroform, room t., 24 h |

|

- 16

-

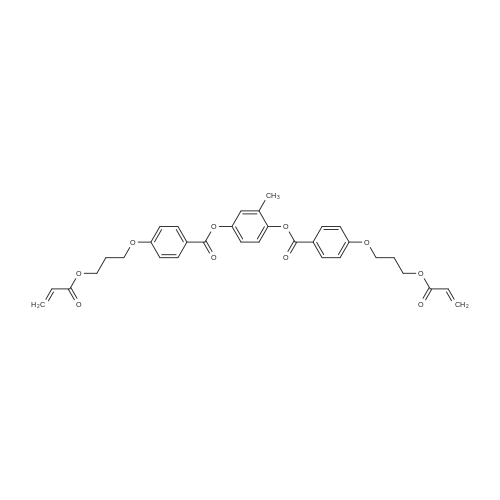

[ 174063-87-7 ]

[ 174063-87-7 ]

-

C31H40O5

[ No CAS ]

-

[ 83847-14-7 ]

[ 83847-14-7 ]

-

None

[ No CAS ]

| Yield | Reaction Conditions | Operation in experiment |

|

With 2-methyl-1-[4-(methylthio)phenyl]-2-morpholinopropan-1-one In cyclohexanone; toluene UV-irradiation; |

1

A solid, in which 40 % by weight of the compound of the Formula 1, 27 % by weight of the compound of the Formula 2, 27 % by weight of the compound of the Formula 3, and 6.0 % by weight of Irgacure907 (manufactured from the company Ciba-Geigy, Switzerland) were mixed, was dissolved in a mixed solvent including 70 % by weight of toluene and 30 % by weight of cyclohexanone so that content of the solid can be 25 % by weight, to prepare a polymerizable and reactive liquid crystalline EPO mixture solution.[110] A fluorocarbon-based surfactant Novec (trade name, manufactured from the company 3M, U.S.A.) FC4430 was added to the polymerizable and reactive liquid crystalline mixture solution so that its content can be 1.0 % by weight, based on 100 % by weight of the solid included in the entire solution.[Ill] The triacetyl cellulose film (trade name: 80UZ, manufactured from the companyFuji, Japan) was corona discharge-treated, and then coated with the polymerizable and reactive liquid crystalline mixture solution including the surfactant using a wire-bar coater (No.4), kept at 50°C in a drying oven for 2 minutes, and then cured once at a rate of 3 m/min using a 80 W/cm high-pressure mercury lamp. The resultant liquid crystal film was clear and its thickness was 1.0 D. |

Chemistry

Chemistry

Pharmaceutical Intermediates

Pharmaceutical Intermediates

Inhibitors/Agonists

Inhibitors/Agonists

Material Science

Material Science

For Research Only

For Research Only

110K+ Compounds

110K+ Compounds

Competitive Price

Competitive Price

1-2 Day Shipping

1-2 Day Shipping