Textile Art

Buying the wool

Generations ago people raised and sheared the sheep but now we buy the wool.

We buy raw wool or thread.

Every 3 or 4 months we are offered raw wool from nearby ranches in the highlands, which is where the wool tends to grow better.

We try to make sure that the wool is of high quality, that it is clean and that the fibers are long.

Carding

Once the wool is dry it is carded or “brushed”

We do the carding in the afternoon as form of resting (from other tasks); we do some carding each day so we don’t have an estimate of how long it takes

After the carding, when the wool is fluffy like a cloud, we spin it into tread with a spinning wheel.

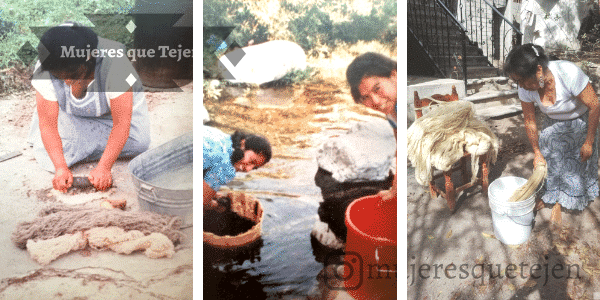

First washing

There is a first washing process to remove any dirt and grease from the wool.

After this first washing to remove any dirt and grease, the wool is put out to dry.

It has to be washed on a sunny day so that it won’t retain humidity or any unpleasant odor.

Spinning

The characteristics of the thread depend on what it will be used for.

For example: the thread used for the weft of a rug must be resistant enough to support tension so it has to be thicker and more tightly twisted. If it is for a fabric it can be looser but must be very even.

This is a tedious task that requires a lot of skill and is in danger of disappearing because generally only older women do. All of our members know how to spin but Adela, Rosa and Josefina are the ones who usually do it.

It takes approximately 6 to 8 hours to make a kilogram of wool thread.

At this point we may combine different colors of natural wool to obtain a variety of tones.

Second washing

Once the wool has been spun it is washed again with a type of tubercular called amole which is used instead of detergent

Once the wool has been spun it is washed again with a type of tubercular called amole which is used instead of detergent

The dyeing process actually begins with gathering the fruits, flowers and mosses we use and ends when the wool has been dyed but the steps don’t necessarily follow one after the other because the fruits, flowers and mosses are gathered seasonally and then stored throughout the year and the dyeing depends on the specific use or project.

The colors we will use and the amount of wool we need are determined by what we are going to make (rugs, bags, garments, etc.)

The dyeing process can take from a week to 10 days to produce all the colors that will be needed.

Collecting flowers and fruits

We use wild fruits and flowers that grow around Teotitlán del Valle, which are collected when they are in season and then stored throughout the year.

Cempasuchil and pericon flowers are gathered in October, ¿…? They are dried in a way that they become dehydrated and do not rot and then are used little by little throughout the year.

Most of the gathering takes place near the end of the year

Some years we are not able to gather moss or pericon.

Once the fruits flowers and mosses have been collected they have to be cleaned before the dyes are extracted.

Flowers, fruits and mosses for natural dyes

Red tones are derived from the cochinlla, which can be mixed with lemon to produce different hues or bathed with pericón to make shades of orange.

We get tones of yellow from cempasúchil, zacatlaxcalli or bejuco

Various shades of blue are obtained from indigo

Huizache is used to make dark grays or black

We get a melón color from achiote.

Walnut is used to obtain various shades of brown depending on whether one uses the leaves or the shells when they are green.

Pericon provides mustard tones.

Moss is used for green tones.

Grinding with a metate

Cochinilla, indigo and achiote seeds are ground into powder with a metate.

The amount needed depends on the intensity of the color you want. An intense color requires from 250 to 300 grams per kilogram of wool. It takes from 15 to 20 minutes to grind this amount with a metate.

The amount of wool required depends on the product you are going to make: a handbag, a rug, a garment, etc. For example a handbag requires approximately half a kilogram of wool; a small rug, 60 x 100 centimeters requires about 1 kilogram of wool.

Extracting natural dyes

Each flower or fruit has a specific process, but most begin with boiling.

Generally leaves, bark and shells are boiled a day beforehand to extract the dyes. We begin with a low flame and then increase the temperature to the boiling point; then we leave a medium flame all night until all the wood burns and the contents cools to the surrounding temperature. The mixture is strained to eliminate the residues and leave only the dye. This is the process we use with cempasuchil, zacatlaxcalli, walnut leaves, pericon and mosses.

Huizache requires a different process. It is crushed then placed in water with rusted metal and set out in the sun to ferment. This process lasts about a month. Huizache is used to give dark gray wool an intense black tone.

When the huizache dye is ready the wool is put in it to soak and left for 2 or 3 days so that it absorbs the dye completely.

Indigo also requires a fermenting process to produce shades of blue.

Wool dyeing

.

Mordentado (preparing the wool prior to dyeing)

Prior to dyeing the wool is prepared by a mordentado process using potassium alum. This step fixes the color so that the wool does not fade subsequently.

The alum is dissolved in boiling water until liquefied. The wool is boiled in water and the liquefied alum is added, when the boiling point is reached again the flame is lowered ¿? and then the wool is left to cool in this liquid until it reaches the surrounding temperature. This process is similar to that of extracting the natural dyes and it requires another whole day.

The wool has to be wet (or damp), it should not be dried before putting it in the dye.

Third washing

Once again the wool is washed to eliminate excess dye and to make sure that the color will not wash out.

The dyed wool is hung to dry in the shade (it takes all day).

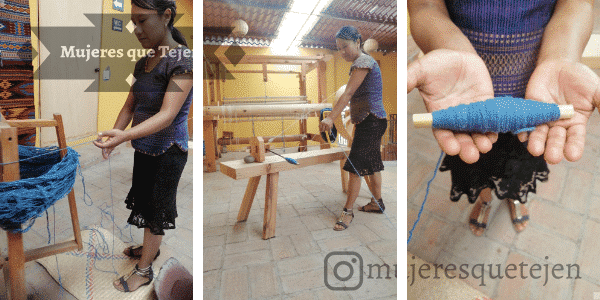

-Encanillar / enrollar en carrizo-

Once the skeins that were dyed and washed have dried they need to be wound on a bobbin to be ready for weaving

The dyed thread is placed on a winder which needs to be turned so the thread can be wound with the spinning wheel.

Leisu lady / preparing the framework

Liesu lady is the Zapotec word that describes the process of preparing the framework

The framework consists of the threads that run inside the piece to be woven and they determine the length and width. –Para realizarlo nos apoyamos de unos postes que tenemos en el piso y vamos caminando alrededor de ellos colocando el hilo, en la punta se hace un ocho para que no se enreden, se quitan de los palos y se pasa al telar y se va amarrando uno por uno hasta que queden todos amarrados. —

Urdido

The urdido is the process of knotting each thread

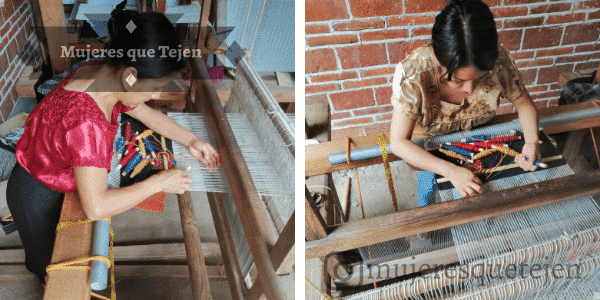

Woven Fabric in the loom

Most of the designs are geometric and they are determined by counting the threads. For a figurative design, paper, where the design has been traced with ink, is placed underneath the framework and used as a guide.

Once finished the piece has to be untied; there is a special knot used to unite the threads one by one.

Cleaning

Once a piece is finished it is taken off the loom and cleaned to remove any knots, thorns, etc.

They have to be tucked in so they don’t frey

-The tips must be —- to prevent —

Once the piece is completed the ends have to be finished or braided depending on whether it has a fringe or tassels or not.