Abstract

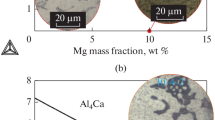

A comparative analysis of the phase composition and morphology of primary crystals in hypereutectic alloys of the Al–Ca–Ni–X system (where X is Fe, Si, Mn) has been carried out by calculation and experimental methods, including the construction of liquidus surfaces. Additional alloying of the base Al–6% Ca–3% Ni alloy with iron and silicon leads to the formation of coarse elongated primary crystals up to 100 μm in length. It is found that the addition of manganese, on the contrary, leads to the formation of relatively small (average size about 20 μm) compact primary crystals of two four-component phases. Presumably, they are phases based on ternary compounds Al9CaNi and Al10CaMn2. The composition of eutectics in quaternary alloys has been determined. All aluminum–calcium eutectics are characterized by a higher proportion of the second phases and a thinner structure compared to the aluminum–silicon eutectic in AK18 silumin, and they are also capable of spheroidization upon heating, starting from 500°C. The combination of compact and spherical particle morphology after annealing in the 63-2Mn alloy appears to be favorable for deformation. A comparison of the manufacturability of the experimental Al–8% Ca–1% Ni–2% Mn alloy and AK18 grade silumin shows the advantage of the former. In terms of the totality of its characteristics, the experimental alloy can be considered the basis for the development of new-generation hypereutectic alloys as an alternative to piston silumins of the AK18 type. The experimental alloy, the microstructure of which is characterized by a compact morphology and small size of primary crystals and a fine structure of the eutectic, unlke hypereutectic silumins, does not require special modification.

Similar content being viewed by others

Notes

Here and further, wt % is considered unless otherwise noted.

REFERENCES

Hatch, J.E., Aluminum: Properties and Physical Metallurgy, Materials Park, OH: American Society for Metals, 1984.

Polmear, I., StJohn, D., Nie, J.F., and Qian, M., Physical metallurgy of aluminium alloys, in Light Alloys, London: Elsevier, 2017, pp. 31–107.

Gloria, A., Montanari, R., Richetta, M., and Varone, A., Alloys for aeronautic applications: state of the art and perspectives, Metals, 2019, vol. 9, p. 662. https://doi.org/10.3390/met9060662

Graf, A., Aluminum alloys for lightweight automotive structures, in Materials, Design and Manufacturing for Lightweight Vehicles, London: Elsevier, 2021, pp. 97–123. https://doi.org/10.1016/B978-0-12-818712-8.00003-3

Jorstad, J. and Apelian, D., Hypereutectic Al–Si alloys: Practical casting considerations, Int. J. Metalcast., 2009, no. 3, pp. 13–36. https://doi.org/10.1007/BF03355450

Belov, N.A., Belov, V.D., Savchenko, S.V., Samoshina, M.E., Chernov, V.A., and Alabin, A.N., Porshnevye siluminy (Piston Silumins), Moscow: Ruda i Metally, 2011.

Zhang, H-h., Duan, Hm., Shao, G., and Xu, L., Microstructure and mechanical properties of hypereutectic Al–Si alloy modified with Cu-P, Rare Met., 2008, vol. 27, no. 1, pp. 59–63.

Zhu, Q., Rassili, A., Midson, S.P., and Hu, X.G., Thixoforming of hypereutectic AlSi12Cu2NiMg automotive pistons, Solid State Phenom., 2019, vol. 285, pp. 446–452. https://doi.org/10.4028/www.scientific.net/SSP.285.446

Prudnikov, A.N., Deformable heatproof transeutectic silumin for pistons, Steel Transl., 2009, vol. 39, no. 456, pp. 456–459. https://doi.org/10.3103/S0967091209060047

Naumova, E.A., Use of calcium in alloys: From modifying to alloying, Russ. J. Non-Ferrous Met., 2018, vol. 59, no. 3, pp. 284–298. https://doi.org/10.3103/S1067821218030100

Belov, N.A., Naumova, E.A., and Akopyan, T.K., Evtekticheskie splavy na osnove alyuminiya: novye sistemy legirovaniya (Eutectic Alloys Based on Aluminum: New Alloying Systems), Moscow: Ruda i Metally, 2016.

Belov, N.A., Naumova, E.A., Akopyan, T.K., and Doroshenko, V.V., Phase diagram of the Al–Ca–Fe–Si system and its application for the design of aluminum matrix composites, JOM, 2018, vol. 70, no. 11, pp. 2710–2715. https://doi.org/10.1007/s11837-018-2948-3

Belov, N.A., Naumova, E.A., Bazlova, T.A., and Doroshenko, V.V., Phase composition and hardening of castable Al–Ca–Ni–Sc alloys containing 0.3% Sc, Met. Sci. Heat Treat., 2017, vol. 59, pp. 76–81. https://doi.org/10.1007/s11041-017-0106-0

Naumova, E.A., Akopyan, T.K., Letyagin, N.V., and Vasina, M.A., Investigation of the structure and properties of eutectic alloys of the Al–Ca–Ni system containing REM, Non-Ferrous Met. (Moscow, Russ. Fed.), 2018, no. 2, pp. 24–29. https://doi.org/10.17580/nfm.2018.02.05

Petzow, G. and Effenberg, G., Ternary Alloys: A Comprehensive Compendium of Evaluated Constitutional Data and Phase Diagrams, Berlin, Weinheim: Wiley-VCH, 1990, vol. 3.

Mondolfo, L.F., Aluminium Alloys: Structure and Properties, London: Butterworths, 1976, pp. 806–841.

Glazoff, M., Khvan, A., Zolotorevsky, V., Belov, N., and Dinsdale, A., Casting Aluminum Alloys: Their Physical and Mechanical Metallurgy, London: Elsevier, 2018. https://doi.org/10.1016/C2015-0-02446-7

Naumova, E.A., Petrov, M.A., Stepanov, B.A., and Vasilieva, E.S., Stamping with torsion of the Al–Ca alloy workpiece with high concentration of Al4Ca, Tsvetn. Met. (Moscow, Russ. Fed.), 2019, no. 1, pp. 66–71.

Rogachev, S.O., Naumova, E.A., Vasileva, E.S., Magurina, M.Yu., Sundeev, R.V., and Veligzhanind, A.A., Structure and mechanical properties of Al–Ca alloys processed by severe plastic deformation, Mater. Sci. Eng., A, 2019, vol. 767, article no. 138410. https://doi.org/10.1016/j.msea.2019.138410

Rogachev, S.O., Naumova, E.A., Sundeev, R.V., and Tabachkova, N.Yu., Structural and phase transformations in a new eutectic Al–Ca–Mn–Fe–Zr–Sc alloy induced by high pressure torsion, Mater. Lett., 2019, vol. 243, pp. 161–164. https://doi.org/10.1016/j.matlet.2019.02.043

Thermo-Calc Software TTAL5 Al-Alloys. https:// www.thermocalc.com. Accessed February 17, 2019.

Shelekhov, E.V. and Sviridova, T.A., Programs for X‑ray analysis of polycrystals, Met. Sci. Heat Treat., 2000, vol. 42, pp. 309–313. https://doi.org/10.1007/BF02471306

Belov, N.A., Diagrammy sostoyaniya troinykh i chetvernykh system. Uchebnoe posobie dlya vuzov (State Diagrams of Ternary and Quaternary Systems. Student’s Book for Institutions of Higher Education), Moscow: Moscow State Institute of Steel and Alloys (Technological Univ.), 2007.

Funding

This work was supported by the Russian Science Foundation, project no. 20-19-00746.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by A. Muravev

About this article

Cite this article

Belov, N.A., Naumova, E.A., Doroshenko, V.V. et al. Comparison of the Effect of Ni, Mn, Fe, and Si Additives on the Microstructure and Phase Composition of Hypereutectic Aluminum–Calcium Alloys. Russ. J. Non-ferrous Metals 63, 71–80 (2022). https://doi.org/10.3103/S1067821222010060

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821222010060