Science

What is Material Science?

Indeed, we live in a material world. Here’s how we use materials to turn a problem-solving idea into actual products.

From the time humans began fashioning rocks into tools, materials have been a cornerstone of civilization and human advancement. Every physical aspect of our lives – from our homes to our devices, our clothes to the way we work and play – stems from developments in materials. Medicine. Transportation. Computers. Communications. Buildings. All the technology we use today would not be possible if we didn’t create the materials needed to make them.

Credits: Lateral Magazine, Materials for the ages

Materials make spaces you thrive in.

At Gush, we tap into this field of science to innovate products that improve your living spaces. As material scientists, we study the relationship between the properties and structure of materials. This knowledge helps us to identify and develop complex materials that can be engineered for various performances, all to help you.

The windows of opportunity that open up with every new material discovery are vast. But we won’t gush too much about that here. As a brief introduction to the wonderful world of material science, let's first understand a foundational principle that guides all our research. Breathe easy: it's pretty straightforward, and pretty cool.

What does Material Science consist of?

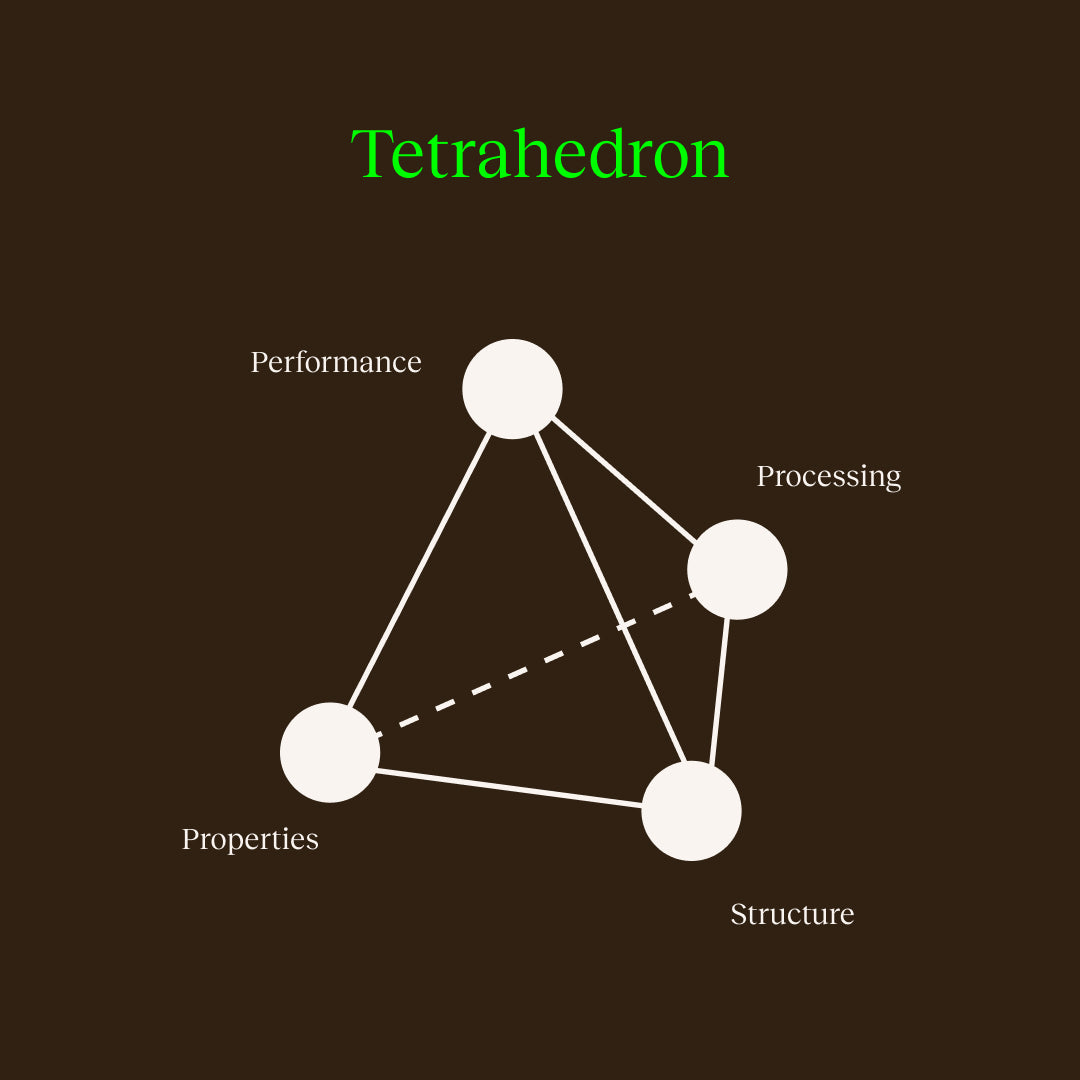

When we’re studying materials for possible products, we consider 4 components: Processing, Structure, Properties and Performance. This is represented by a tetrahedron, as it highlights the components’ interdependence.

But to achieve a certain material application, we look at these components in a linear sequence. To attain a material of a certain performance, you need to create a set of specific properties. The internal structure of the materials is responsible for those properties. The structures are created and influenced by processing the raw material.

In a nutshell, think of the material science research process as answering these key questions in order:

Performance: what function do we need this material to achieve?

Properties: What are the desired properties required for this material to perform this function?

Structure: Which candidate materials have the certain structure and composition to fulfil these properties?

Processing: Which processing method alters the selected raw material into the required structure?

Using this sequence to create materials that fulfil specific tasks forms the base of Gush’s research and development. It’s the means by which we make our ideas a reality.

Now, let’s go deeper into what each component entails. We’ll use the application of hiding power for paints as an example.

Using the Material Science Process in Paint.

Performance

Hiding power is a material feature that’s found in most paints. As its name implies, hiding power refers to the ability of the paint to obscure the surface being painted. This could be the previous colour or patterns, stains, or patch-up work. With good hiding power, you see none of these things – only a smooth, fresh wall. This is achieved through the use of pigments that coat thoroughly, show colour effectively and reflect light appropriately.

Properties

To achieve this performance, we need a material that has suitable properties. This includes aspects such as a high refractive index, good optical stability and chemical inertness. The selected material also has to be compatible with the other surface agents in the paint formulation.

In terms of chemical, photochemical, and physical characteristics, titanium dioxide (TiO2) pigments are found to be a good candidate material. It has a high refractive index, which means that when light hits this pigment, a significant portion of the light gets scattered. This gives the paint high opacity and helps colours look vivid. These characteristics are determined principally by the particle size of the pigment and the chemical composition of the material surface.

In addition, TiO2 pigments don’t penetrate the skin, and bind well with the paint formulation. This means that the risk of inhalation is safely low, and skin contact with painted surfaces does not pose safety hazards.

Structure

Under certain conditions, TiO2 particles tend to agglomerate or clump together. This affects properties such as gloss, opacity, tint strength, and storage stability. So, in order to achieve the properties we need, we have to adapt the particle surface structure of the titanium dioxide (TiO2) pigment. This is done through surface treatment agents. Most commercial grades of titanium dioxide undergo inorganic and, in some cases organic surface treatments.

Inorganic surface treatment agents coat TiO2 particles with inorganic materials like silica and aluminium oxide. Doing this improves its chemical and performance properties such as dispersibility, hiding power efficiency, chalk resistance, and resistance to discoloration by heat and/or photoreduction.

Organic surface treatment agents, on the other hand, usually use polyols, organic amines, or organosilicon (siloxanes and silicones). Because this surface treatment modifies the surface polarity of titanium dioxide, it enhances the surface wetting and dispersing properties of TiO2 pigment in various media. Such treatments improve TiO2’s dispersibility in aqueous systems, which is useful for water-based paint formulations and improving the gloss of coatings.

Processing

TiO2 pigments are obtained by processing raw materials. This is commonly extracted from the mineral ores of ilmenite, rutile and anatase. The ore then needs to be refined and purified into a useful form (i.e. pigments) with the controlled structural features and properties that we require.

Material processing methods like hydrolysis and calcination develop the structural features (i.e. crystal structure, microstructure, size, and shape) necessary for the TiO2 to function effectively in its intended application.

Using the linear sequence of the components in the material science tetrahedron, you can see how we take raw, natural materials and engineer them to create useful products. In this way, thousands of products are created that we use in our everyday lives.

And there’s still plenty of room for innovation. Many companies, scientists and engineers are designing more sustainable methods, to make products that don’t deplete the earth’s natural resources or produce waste that worsens climate change. Like them, we’re focused on innovating products that are sustainable and use closed-loop processes. So that everyone’s future with our planet is harmonious and mutually supportive.